Roll forming is a type of rolling that involves continuously bending long strips of metal sheet (typically coiled steel) into the desired cross-section.

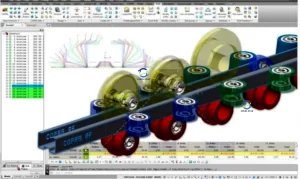

Design the mold shape and number of groups according to the required size. The shrinkage ratio of each group of cold bending is different. Through cold bending group by group, the final desired size can be achieved. Combined with electronic control system, hydraulic system, shearing system and counting encoder to realize automated operation.

Technical Parameters :

- Raw material width : 200mm — 600mm (Can be customized according to your needs)

- Thickness of sheet : 0.3mm — 0.8mm (Can be customized according to your needs)

- speed : 10 m — 30 m/min (Can be customized according to your needs)

- Voltage : 380v 50hz 3phase / 220v 60hz 3phase (Can be customized according to your needs)

- Language : English / Spanish / Arabic / Russian / Portuguese / German / French (Can be customized according to your needs)

- Material of rollers : C45 / Gcr15 / Cr12 / Cr12 Mov (Can be customized according to your needs)

- Motor brand : Siemens / other (Can be customized according to your needs)

- Electronic control PLC : Siemens / Delta / other (Can be customized according to your needs)

- Number of roller rows: According to product design

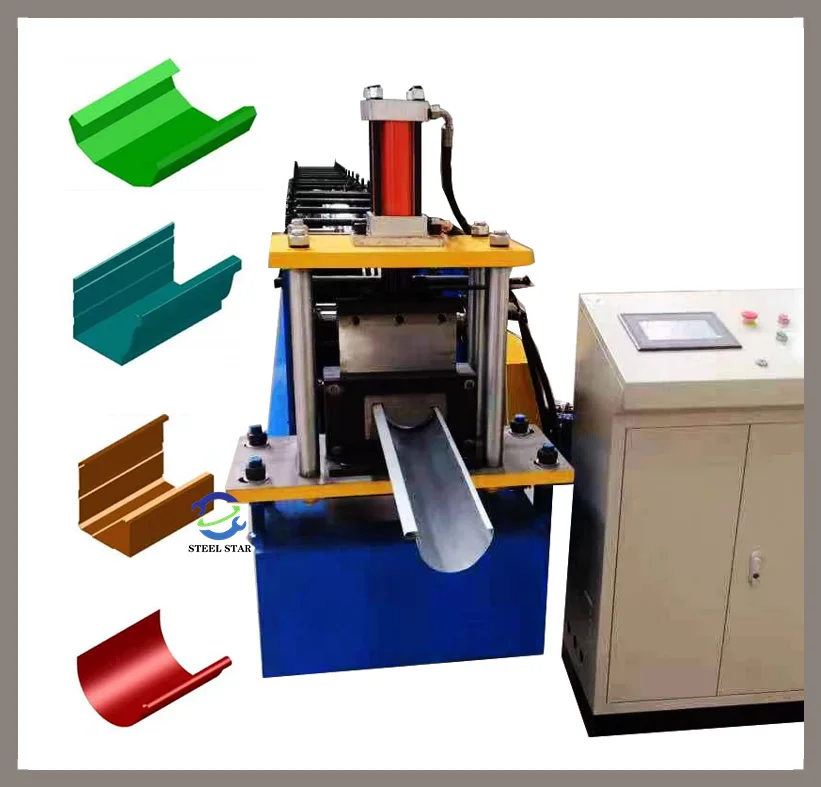

Application Scenarios :

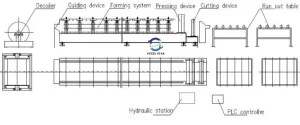

Equipment Production Line:

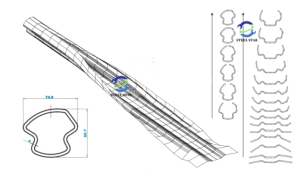

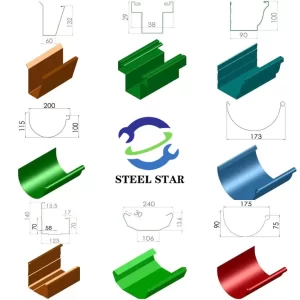

Related Product Layout Diagrams:

How to install a color steel plate sink :

I. Preparation before installation

1.1. Choose a suitable color steel plate sink and understand the size and installation method of the sink.

1.2. Purchase installation materials: wrench, electric drill, screws, glue, water pipes, etc.

1.3. Determine the installation location of the sink and reserve enough installation space.

1.4. Check whether the water pipe is unobstructed and whether the water valve is working properly.

II. Installation steps

2.1. Install the faucet and spout.

Insert the faucet and spout into the holes on the sink and fix them with screws.

2.2. Install the downpipe and drain.

Insert the downpipe and drain into the hole under the sink and fix it with screws. Note that the position of the drain should be aligned with the pipe.

2.3. Install the sink bracket.

Install the sink on the bracket and fix it with screws. Note that the position of the bracket should be aligned with the sink.

2.4. Install the tap water pipe and water valve.

Connect the tap water pipe and water valve and fix them with screws.

2.5. Install water pipes and drain pipes.

Connect the water pipes and drain pipes, and make sure the connection is firm.

2.6. Clean and test.

After installation, clean the inside of the sink and open the water valve to test whether the water flow is normal.

III. Precautions

3.1. Before installing the color steel plate sink, check the position of the water pipes and power cords to avoid damage during installation.

3.2. The sink should remain stable after installation and should not tilt or shake.

3.3. Pay attention to safety during installation to prevent accidents.

IV. Solutions to common problems

4.1. The sink is not draining smoothly. The reason may be that the sewer pipe is blocked or the sink is not in the right position. It should be cleaned and adjusted in time.

4.2. The sink is leaking. The reason may be that the sink is leaking. It should be treated with glue.

4.3. The sink is leaking. It may be leaking at the connection between the faucet and the faucet. The screws should be tightened or the sealing gasket should be replaced.

The above is the installation method and precautions of the color steel plate sink. As long as you install it correctly according to the steps, you can enjoy the convenience and comfort brought by the convenient and practical sink.

How to choose a suitable gutter roll forming machine?

1. Material adaptability and process requirements

Processing material matching

Prioritize the equipment that is compatible with a variety of metal coils such as stainless steel, color steel, aluminum, etc. Conventional models support plate processing with a thickness of 0.3-1.2mm, and special requirements can be customized to expand to 1.5mm.

If you need to process pre-coated steel coils or lightweight alloys (such as magnesium and aluminum), you need to confirm whether the equipment is equipped with a progressive shaping wheel design to reduce deformation caused by uneven bending stress.

Forming section requirements

Clarify the cross-sectional shape of the gutter (such as U-shaped, square, round), and choose a model that supports fast switching of multiple molds to avoid groove depth errors caused by mold mismatch.

2. Equipment performance and technical configuration Forming precision control

Prioritize models equipped with intelligent correction systems and servo motors to ensure that the longitudinal deviation is ≤0.1mm and the angle deviation is ≤0.5° during pipe rolling.

The hydraulic transmission system needs to support real-time pressure adjustment to avoid damage to the galvanized layer or deformation of the pipe body due to pressure fluctuations.

Production efficiency and energy consumption

Fully automatic models are recommended to have a forming speed of no less than 5m/min, and are equipped with automated unwinding and shearing modules to reduce the frequency of manual intervention.

In 2025, new models generally integrate energy consumption monitoring functions, which saves about 15% energy compared to traditional equipment and is suitable for long-term production needs.

III. Functional modules and scalability

Core function configuration

Basic equipment includes at least rolling and trimming modules; high-end models can expand elbow forming, automatic stacking and other functions to meet the needs of complex scenarios such as photovoltaic water tanks2.

Mold replacement requires standardized interfaces to support non-standard customization (such as special-shaped cross-section molds) and shorten the secondary development cycle.

Intelligent upgrade potential

Select equipment with reserved PLC or CNC system interfaces to facilitate the installation of remote monitoring, fault diagnosis and other modules in the future.

IV. Manufacturer service and cost evaluation

Equipment procurement cost

The budget needs to be balanced in combination with production capacity requirements.

After-sales service guarantee

Preferentially choose manufacturers that provide lifetime mold maintenance and on-site debugging guidance (such as manufacturers in Cangzhou, Hebei). Confirm whether it includes concrete mix recommendations (if composite structure construction is required) and the supply time of emergency accessories.

V. Operation specifications and safety requirements

Operation compatibility

The equipment must comply with the “Technical Specifications for Grooved Pipe Connections” and support standardized operating procedures such as horizontal fixing of pipes and vertical adhesion of end faces.

The grooving process must support the segmented pressurization mode to avoid single overpressure damage to the plate strength.

Factory Information:

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)

Key points for maintenance of gutter roll forming machine

I. Mechanical system maintenance

Daily cleaning and inspection

Roller and mold cleaning: Clean the residual metal chips and oil on the roller surface after daily shutdown, use special cleaning tools to avoid scratching the surface, and wipe the mold contact surface with alcohol to remove impurities38.

Transmission component inspection: Check the meshing state of the chain and gear. If abnormal noise or wear is found, stop the machine immediately to adjust the tension or replace accessories.

Hydraulic system management

Oil monitoring: Regularly check the viscosity and contamination of the hydraulic oil. When it is turbid or emulsified, it is necessary to replace new oil. The tank cleaning cycle does not exceed 1 year.

Pipeline maintenance: Check the oil leakage of the hydraulic pipeline joints every week, replace the aging seal ring, and ensure that the system pressure is stable within the equipment calibration range.

II. Electrical and control system

Line and component maintenance

Check whether the line terminals in the control cabinet are loose, the integrity of the sensor wiring, and the error of the calibrated temperature and pressure monitoring module (allow ±1℃/±0.1MPa) every month.

Clean the dust from the heat dissipation port of the electric control cabinet to avoid overheating of components due to poor heat dissipation.

3. Special maintenance of molds and rollers

Rust prevention of molds

If the shutdown time exceeds 48 hours, anti-rust oil should be applied to the mold surface. High-temperature resistant lithium-based grease should be used first to prevent oxidation and shedding of the zinc plating layer.

Progressive wear repair

Measure the depth of the mold groove regularly. When the wear exceeds 0.3mm, repair welding or replace the new mold to avoid dimensional deviation of the molded parts.

4. Lubrication management specifications

Key lubrication points

Lubricating oil should be added to the guide rails and lead screws every week, grease should be added to the bearings every 200 working hours, and the chain should be lubricated with oil immersion (ISO VG220 gear oil is recommended).

Lubricant selection

Molybdenum disulfide grease should be used first in high-temperature working conditions to prevent the roller from getting stuck due to lubrication failure.