Roll forming is a type of rolling that involves continuously bending long strips of metal sheet (typically coiled steel) into the desired cross-section.

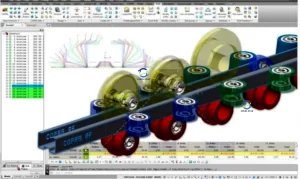

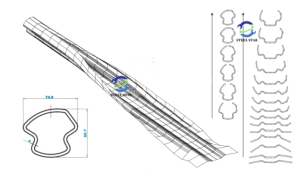

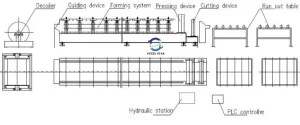

Design the mold shape and number of groups according to the required size. The shrinkage ratio of each group of cold bending is different. Through cold bending group by group, the final desired size can be achieved. Combined with electronic control system, hydraulic system, shearing system and counting encoder to realize automated operation.

Technical Parameters :

- Raw material width : 300mm — 600mm (Can be customized according to your needs)

- Thickness of sheet : 0.3mm — 0.8mm (Can be customized according to your needs)

- speed : 2 m — 8 m/min (Can be customized according to your needs)

- Voltage : 380v 50hz 3phase / 220v 60hz 3phase (Can be customized according to your needs)

- Language : English / Spanish / Arabic / Russian / Portuguese / German / French (Can be customized according to your needs)

- Material of rollers : C45 / Gcr15 / Cr12 / Cr12 Mov (Can be customized according to your needs)

- Motor brand : Siemens / other (Can be customized according to your needs)

- Electronic control PLC : Siemens / Delta / other (Can be customized according to your needs)

- Number of roller rows: According to product design

Application Scenarios :

Equipment Production Line:

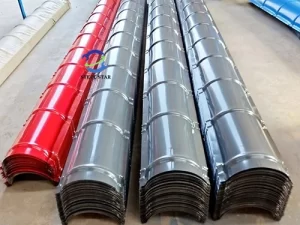

Related Product Information:

Preparation work

1. Prepare the color steel ridge tiles to be installed, and ensure that the quantity, model, size, etc. meet the requirements;

2. Confirm whether the roof structure where the color steel ridge tiles are to be installed meets the requirements, and repair them in time if any problems are found;

3. Remove the debris on the top of the roof to make it clean and tidy;

4. Prepare the necessary tools: lifting rope, hand drill, electric hammer, screwdriver, etc.;

Installation steps

1. Determine the installation position of the color steel ridge tiles and place the ridge tiles in the corresponding position;

2. Fix the ridge tiles and use screws to firmly fix the ridge tiles on the roof;

3. Next, according to the direction of the ridge tiles, install the next ridge tile on the previous one until it is installed to the end of the roof;

4. Pay attention to the treatment of the interface, and ensure that the interface is sealed to avoid water leakage;

5. After reaching the end of the roof, if the ridge tile is too long, you can use a hand drill to cut the ridge tile to the required length;

6. After the installation of the color steel ridge tiles is completed, conduct a final inspection.

Precautions

1. Pay attention to your own safety during the installation process and take safety measures;

2. When laying, the interface of the ridge tile should not be too long and should be controlled at about 400 mm;

3. When installing the color steel ridge tile, pay attention to the direction of the wind. If it is a windy season, be extra careful;

4. Avoid contact between the color steel ridge tile and sharp objects. If there is hail and other weather, it should be handled in time;

5. After the installation is completed, clean up the garbage left on the roof and conduct a final inspection.

In short, the installation of the color steel ridge tile is not difficult. As long as you master the correct methods and precautions, you can complete it successfully.

Factory Information:

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)