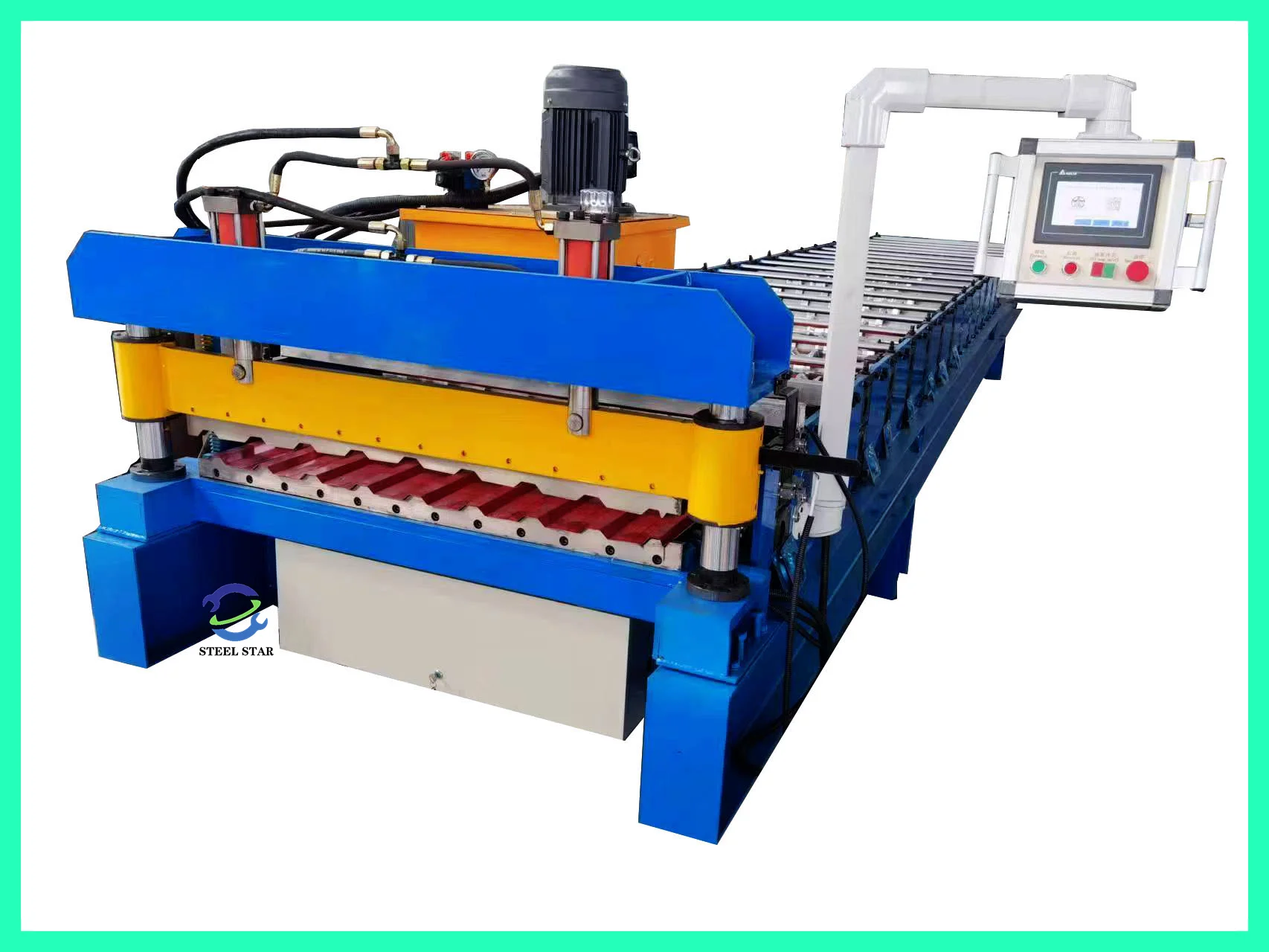

Roll forming is a type of rolling that involves continuously bending long strips of metal sheet (typically coiled steel) into the desired cross-section. Design the mold shape and number of groups according to the required size. The shrinkage ratio of each group of cold bending is different. Through cold bending group by group, the final desired size can be achieved. Combined with electronic control system, hydraulic system, shearing system and counting encoder to realize automated operation.

Technical Parameters :

- Raw material width : 914mm / 925mm / 1000mm / 1200mm / 1220mm / 1250mm (Can be customized according to your needs)

- Thickness of sheet : 0.15mm — 1.0mm (Can be customized according to your needs)

- speed : 15 m — 5 0 m/min (Can be customized according to your needs)

- Voltage : 380v 50hz 3phase / 220v 60hz 3phase (Can be customized according to your needs)

- Language : English / Spanish / Arabic / Russian / Portuguese / German / French (Can be customized according to your needs)

- Material of rollers : C45 / Gcr15 / Cr12 / Cr12 Mov (Can be customized according to your needs)

- Motor brand : Siemens / other (Can be customized according to your needs)

- Electronic control PLC : Siemens / Delta (Can be customized according to your needs)

- Number of roller rows: According to product design

Application Scenarios :

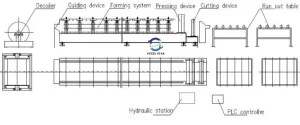

Equipment Production Line:

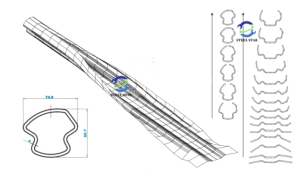

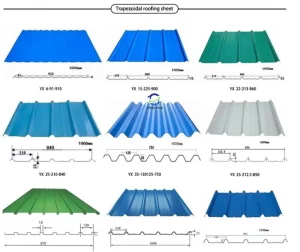

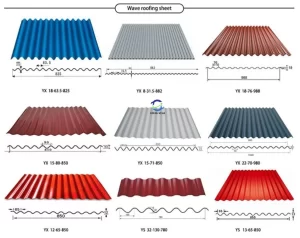

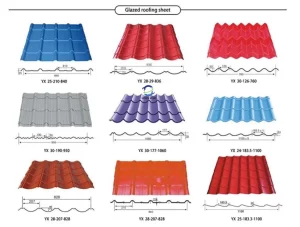

Related Product Layout Diagrams:

Color steel roof panels are a kind of roof covering material that uses color-coated sheets as panel materials. Its specifications include thickness, width and length. Color steel roof panels have the characteristics of good weather resistance, good waterproofness, lightweight, etc., and are suitable for various harsh climate conditions. During installation, attention should be paid to foundation treatment, construction sequence and expansion and contraction space at the overlap. Reasonable selection and use of color steel roof panels can effectively improve the quality and service life of the building. Color-coated steel roof panels are a kind of roof covering material that uses color-coated sheets as panel materials and is pressed by a cold-bending forming machine.

Color steel roof panels are a kind of roof covering material that uses color-coated sheets as panel materials. Its specifications include thickness, width and length. Color steel roof panels have the characteristics of good weather resistance, good waterproofness, lightweight, etc., and are suitable for various harsh climate conditions. During installation, attention should be paid to foundation treatment, construction sequence and expansion and contraction space at the overlap. Reasonable selection and use of color steel roof panels can effectively improve the quality and service life of the building. Color-coated steel roof panels are a kind of roof covering material that uses color-coated sheets as panel materials and is pressed by a cold-bending forming machine.

Commonly used specifications and sizes of color steel roof panels are as follows:

1. Thickness: Common color steel roof panel thicknesses include 0.4mm, 0.5mm, 0.6mm and other options. The selection of thickness should be determined according to the specific situation. Generally speaking, when the roof span and rainfall are large, thicker color steel roof panels should be selected to ensure the load-bearing capacity and durability of the roof.

2. Width: Common color steel roof panel widths have optional ranges, generally 1000mm, 1200mm, 1250mm, etc., of which 1000mm is the most common width. The selection of width mainly considers the roof coverage area and installation process to ensure the installation quality and overall beauty of the roof panels.

3. Length: The length of color steel roof panels is generally customized according to actual needs and can be determined according to the length and overall design of the roof. Common lengths include 2m, 3m, 4m, 5m,6m,etc.

The length should be chosen to minimize the shearing and splicing of panels to ensure the overall performance and waterproofing of the roof. Features of color steel roof panels: 1. Good weather resistance: Color steel roof panels use color-coated panels as panel materials. After advanced coating technology, they have excellent weather resistance and can be used for a long time in harsh climate conditions. They are not easy to fade and age.

2. Good waterproof performance: Color steel roof panels have excellent waterproof performance, and their surface coating has been processed to effectively prevent the penetration of rainwater and ensure the waterproof performance of the roof.

3. Lightweight: Color steel roof panels use thin steel plates as materials, which have lower weight.

They can not only reduce the weight of the building, but also reduce the use of other structural materials and improve the seismic performance of the building. Quality requirements for color steel roof panels:

1. The thickness of the panel must meet the specified standards to ensure the load-bearing capacity and durability of the roof.

2. The adhesion of the coating must meet certain requirements to ensure the weather resistance and waterproofness of the roof panel.

3. The flatness and dimensional accuracy of the panels must meet the requirements to ensure the installation quality and overall beauty of the roof panels.

Key points for installing color steel roof panels:

1. Before installation, basic processing work must be carried out to ensure the flatness and overall stability of the roof panel.

2. The installation of roof panels should be carried out in accordance with the prescribed construction sequence. First, install the upper edge, purlins and lap wings, and then install the roof panels.

3. When installing roof panels, attention should be paid to staggered positions, and a certain amount of expansion space should be left at the overlap to adapt to temperature changes and resist wind and rain. The specifications, characteristics, quality requirements and installation points of color steel roof panels are issues that need to be focused on in building roof design and construction. Reasonable selection and use of color steel roof panels can effectively improve the quality and service life of the building.

Factory Information:

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)