Purlin Roll Forming Machine: The Backbone of Modern Structural Framing

Introduction: The Unseen Skeleton of Industry

Walk into any modern warehouse, aircraft hangar, distribution center, or agricultural building, and you are standing within a framework defined by its purlins—the essential horizontal structural members that span between the primary rafters or trusses, supporting the roof and wall cladding. The machine that makes these critical components, the Purlin Roll Forming Machine, is a specialized piece of industrial equipment dedicated to producing the uniform, high-strength steel profiles that form the primary skeleton of countless industrial and commercial structures worldwide.

What is a Purlin Machine?

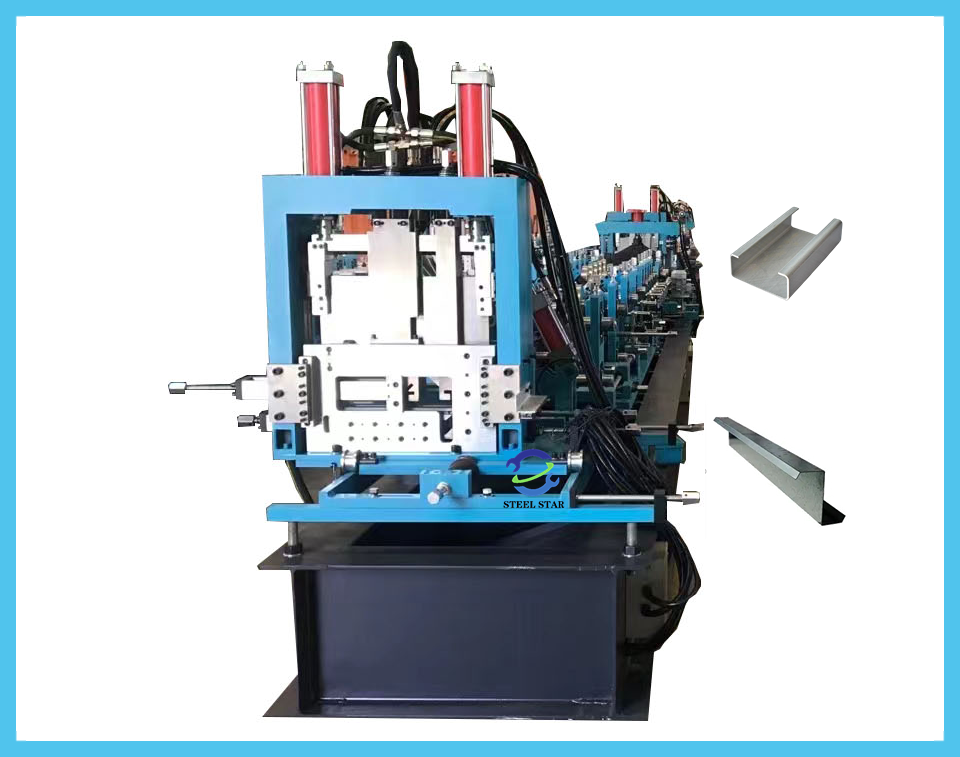

A Purlin Roll Forming Machine is a continuous cold roll-forming production line designed specifically to transform pre-galvanized or painted steel coils into standardized C-sections and Z-sections. These profiles are engineered for optimal strength-to-weight ratio and ease of assembly, forming the backbone of secondary structural framing systems.

Core Machine Function and Profiles

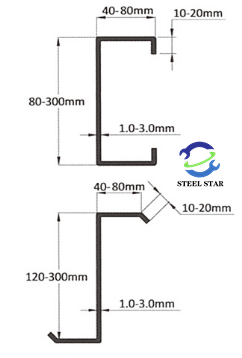

The machine’s core function is to progressively bend a flat metal strip into a precise, long-length structural shape without heat or welding. The two most critical profiles it produces are:

- C-Purlin: A symmetrical channel shape with inward-facing flanges. It is versatile and commonly used for both roof and wall framing, often as rafters or studs.

- Z-Purlin: An asymmetric shape with flanges pointing in opposite directions. This allows them to overlap efficiently at joints, creating a continuous beam over multiple supports. Z-purlins are predominantly used as roof members, offering superior spanning capabilities.

These profiles are produced in standardized depths (e.g., 100mm, 150mm, 200mm, 250mm) and material thicknesses (typically from 1.0mm to 3.0mm), with custom sizes available.

Anatomy of a Purlin Production Line

A complete, automated purlin line integrates several key stations:

- Decoiler/Uncoiler: A heavy-duty unit that holds the large, heavy steel coil (often 3-6 tons) and feeds it into the line under controlled tension.

- Feeding & Leveling Unit: Critical for structural integrity. A series of leveling rollers removes any coil curvature (coil set) and ensures the steel strip is perfectly flat before it enters the forming process.

- Pre-Punching/Hole-Punching Station: This is a defining feature of a purlin machine. A high-precision, servo-controlled punching unit punches a series of holes (for bolts, screws, or conduits) and slots into the flat strip before it is formed. This is vastly more accurate than post-forming punching and is essential for the bolted connections of structural framing.

- Roll-Forming Section: The heart of the machine. A sequence of 12 to 20 paired roll stands, each with precision-machined, hardened steel rollers, progressively bends the flat, punched strip into the final C or Z profile. Each stand makes a small, incremental bend.

- Cut-Off System: A heavy-duty hydraulic flying cut-off system cleanly shears the continuously moving purlin to the exact, pre-programmed length (e.g., 6m, 9m, 12m) without stopping the line.

- Output & Stacking System: A run-out table conveys the finished purlins to an automatic stacker, which organizes them into neat, stable bundles for strapping and crane handling.

- PLC Control System: The central nervous system. A Programmable Logic Controller with a touch-screen interface allows operators to set all parameters—profile dimensions, hole patterns, cut lengths, and quantities—ensuring complete automation and repeatability.

Key Technological Advantages

- Structural Precision: In-line pre-punching guarantees perfect hole alignment, which is non-negotiable for safe and efficient on-site structural assembly.

- High-Speed Production: Modern lines operate at 20-50 meters per minute, producing vast quantities of material for large-scale projects.

- Exceptional Consistency and Quality: Every purlin in a production run is identical, ensuring predictable structural performance and simplifying construction.

- Material and Labor Efficiency: The automated process minimizes scrap and requires minimal manual intervention, optimizing cost.

- Profile Flexibility: By changing the roller dies and punching programs, a single machine can produce a range of C and Z sizes, making it highly adaptable.

Impact on the Construction Industry

The purlin roll forming machine is a cornerstone of Metal Building Systems (MBS) and pre-engineered building construction. Its impact is profound:

- Enabling Rapid Construction: It supplies the standardized, ready-to-assemble components that allow pre-engineered buildings to be erected in weeks rather than months.

- Optimizing Structural Design: The ability to produce long-length, high-strength sections with precise connection points allows engineers to design lighter, more efficient structures.

- Driving Economic Development: By lowering the cost and time of constructing industrial space, it directly supports logistics, manufacturing, and commercial growth.

The Purlin Roll Forming Machine is a masterclass in applied engineering, transforming raw coil steel into the disciplined, high-performance bones of modern infrastructure. It is not merely a manufacturing tool but a critical enabler of efficient, cost-effective, and robust construction. As architecture continues to demand longer spans, smarter use of materials, and faster build times, the technology behind these machines—with increasing automation, data integration, and precision—will remain fundamentally important. In the grand framework of global construction, the humble purlin, and the machine that creates it, truly do carry the weight of industry.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)