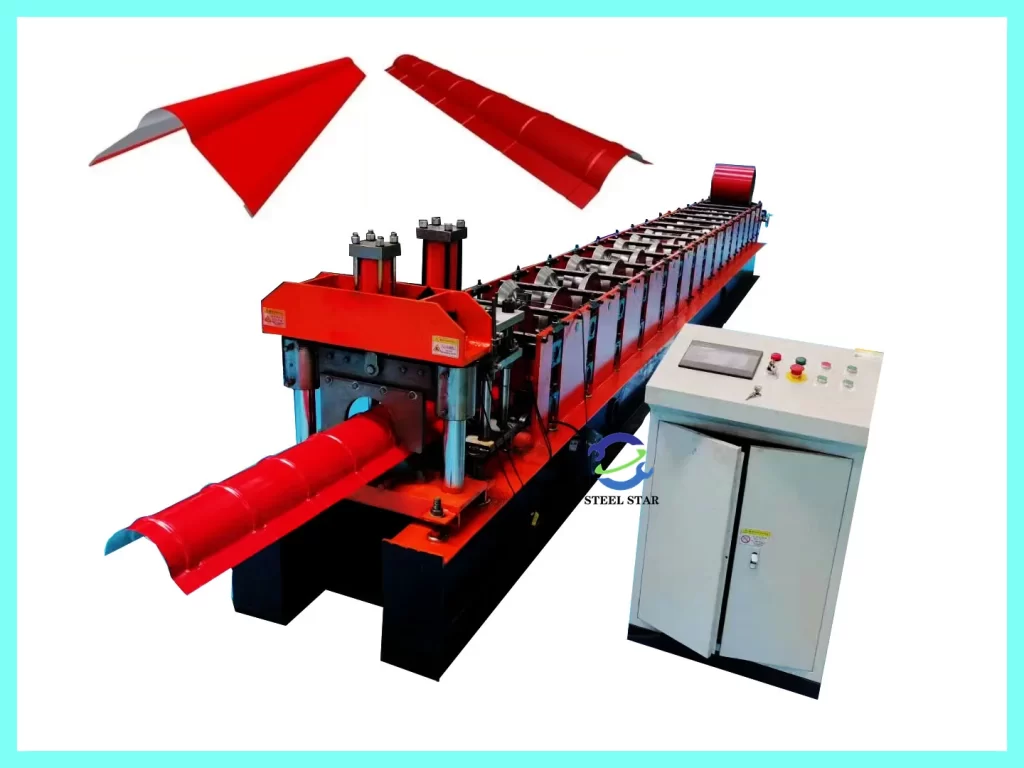

Ridge Cap Roll Forming Machine: Engineering the Peak of Roofing Performance

The ridge cap roll forming machine represents a specialized advancement in metal roofing manufacturing technology, dedicated to producing the critical components that seal and protect the peak of sloped roofs. As an essential element in roofing systems, ridge caps prevent water infiltration, provide ventilation, and deliver finished aesthetic appeal. These precision machines transform metal coils into consistently accurate, high-performance ridge components through automated cold roll forming processes, ensuring weathertight integrity and architectural coherence for residential, commercial, and industrial buildings.

Technical Specifications and Design Features

Core Operational Principle

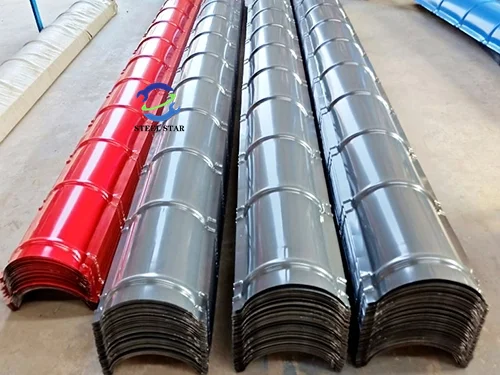

Utilizing progressive cold roll forming technology, the machine processes pre-finished steel, aluminum, or copper coils through a customized series of roller dies. Each station incrementally forms the metal into specific ridge profiles—including standard, hip, vented, and custom architectural designs—with tight dimensional tolerances and excellent repeatability.

Key Performance Parameters:

- Material Thickness Range: 0.4mm – 1.2mm

- Forming Width Capacity: 300mm – 600mm

- Production Speed: 8 – 25 meters per minute

- Power Configuration: 15 – 45 kW three-phase systems

- Profile Variants: 3 – 8 standard configurations

- Tolerance Standards: ±0.3mm dimensional accuracy

Mechanical Components and Integrated Systems

1. Material Handling System

- Dual mandrel decoiler with automatic tension control

- Coil car loading system for continuous operation

- Electro-pneumatic edge guiding mechanism

- Pre-notching and pre-piercing stations

2. Precision Forming Section

- Carbide-enhanced forming rollers (HRC 60-65)

- Quick-change cartridge design for profile switching

- Multi-axis adjustable roll stands

- Closed-loop lubrication with filtration systems

- Thermal management cooling circuits

3. Post-Forming Processing Units

- Servo-driven flying cut-off systems

- Embossing and marking stations

- Automatic stacking and bundling equipment

- Conveyorized discharge systems

4. Control and Monitoring Systems

- Industrial PC with graphical interface

- PLC-controlled synchronization systems

- Length measurement encoders

- Production counting and reporting software

Product Applications and Architectural Integration

Residential Roofing Systems

- Standard ridge caps for asphalt shingle alternative roofs

- Ornamental ridge details for premium architectural projects

- Ventilated ridge systems for attic airflow management

- Snow retention ridge integrations

Commercial and Industrial Applications

- Standing seam compatible ridge profiles

- Wide-span industrial building ridge systems

- Curved and radius ridge capabilities

- High-wind rated mechanical lock systems

Specialized Configurations

- Historical restoration profiles

- Solar panel integration designs

- Cool roof reflective ridge systems

- Heavy-duty industrial ventilation ridges

Performance Advantages

Production Efficiency

- 85-92% material utilization rates

- 400-600% productivity increase over manual fabrication

- Continuous 24-hour operation capability

- Fast changeover (under 20 minutes for preset profiles)

Quality and Consistency

- Uniform cross-sectional accuracy

- Consistent coating integrity maintenance

- Precise mitre cut and notch alignment

- Repeatable mechanical properties

Economic Benefits

- Reduced labor requirements (2-3 operators)

- Lower secondary processing costs

- Minimal material waste

- High return on investment (12-24 month typical ROI)

Technological Innovations

Smart Manufacturing Features

- IoT-enabled performance monitoring

- Predictive maintenance scheduling

- Mobile application remote diagnostics

- Production data cloud integration

Advanced Control Systems

- Automatic profile recognition

- Self-adjusting roll gap compensation

- Energy consumption optimization

- Scrap reduction algorithms

Customization Capabilities

- CAD/CAM profile import functionality

- Variable pitch and angle adjustments

- Integrated foam tape application

- Custom embossing and perforation patterns

Operational Requirements

Installation Specifications

- Foundation requirements: 200mm reinforced concrete base

- Operational space: 20m × 4m minimum floor area

- Utility requirements: Compressed air (6-8 bar), proper ventilation

- Material handling: 2-5 ton overhead crane access

Maintenance Protocols

- Daily visual inspection procedures

- Weekly lubrication schedule adherence

- Monthly roll surface condition assessment

- Quarterly alignment verification procedures

Safety Systems

- Light curtain protection at entry points

- Emergency stop circuits with reset protocols

- Electrical cabinet safety interlocks

- Noise reduction enclosures (optional)

Market Position and Industry Trends

Current Market Status

The global ridge cap forming equipment sector serves a $2.1 billion annual market for metal ridge components. North America and Europe represent mature markets with replacement demand, while Asia-Pacific shows 8-10% annual growth driven by new construction.

Sustainability Developments

- Energy-efficient motor systems

- Water-based lubrication compatibility

- Recycled material processing capability

- Low VOC coating system integration

Future Directions

- Increased automation in material handling

- Enhanced digital twin technology integration

- Broader material compatibility (composites, new alloys)

- Smaller footprint machines for distributed manufacturing

Selection and Implementation

Technical Evaluation Criteria

- Production volume requirements analysis

- Material type and gauge specifications

- Profile complexity and change frequency

- Facility space and utility constraints

- Future expansion considerations

Financial Analysis

- Operating cost structure

- Maintenance contract options

- Training and implementation support

Vendor Assessment

- Industry experience and references

- Technical support response time

- Spare parts inventory availability

- Software update policies

The ridge cap roll forming machine exemplifies the specialization and precision achievable in modern roofing component manufacturing. By combining mechanical engineering excellence with advanced control systems, these machines deliver consistently high-quality products that are essential for complete, weathertight roofing systems. Their efficiency advantages over traditional fabrication methods, combined with growing capabilities for customization and smart operation, position ridge cap formers as valuable investments for roofing manufacturers and metal service centers. As architectural trends continue to emphasize both performance and aesthetics in building envelopes, and as construction practices increasingly favor prefabricated precision components, these machines will continue evolving with enhanced connectivity, greater material flexibility, and improved sustainability features—ensuring their relevance in building the better-protected, more durable roofs of tomorrow. The technology’s ongoing development promises to further bridge manufacturing efficiency with architectural creativity, making customized, high-performance ridge solutions more accessible across global markets.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)