Roll Forming Machine,Roll Forming Machines:

In the realm of modern manufacturing, the roll forming machine stands as a remarkable technological innovation.

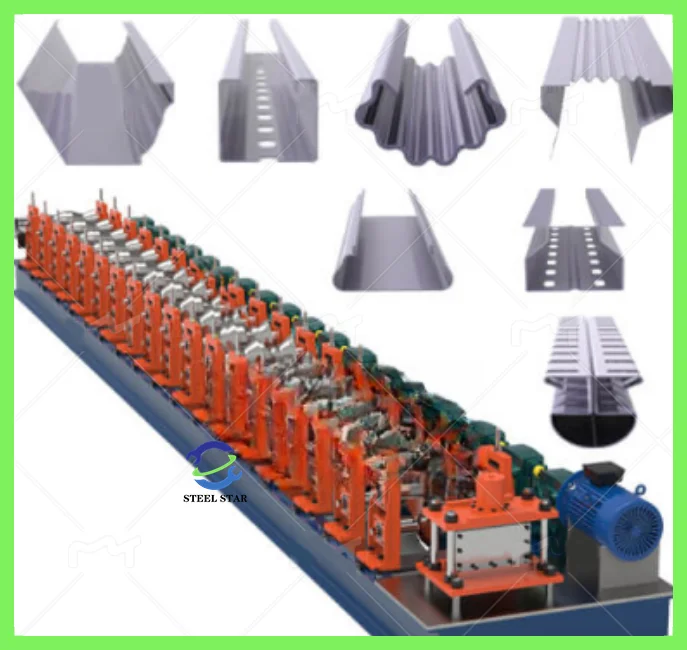

This sophisticated piece of equipment operates on a principle that is both elegant and highly efficient. It takes a long, flat strip of metal, such as steel or aluminum, and gradually transforms it into a complex and precise cross-sectional profile. As the metal strip passes through a series of meticulously designed rollers, each roller imparts a specific bend or shape change. The cumulative effect of this sequential process is the creation of a finished product with a consistent and accurate form.

Roll forming machines find extensive applications across diverse industries. In the construction sector, they are used to produce metal roofing sheets that offer durability and weather resistance. Metal studs for framing walls are also fabricated using these machines, providing strength and stability to building structures. The automotive industry benefits from roll formed parts in the manufacturing of chassis components and trim pieces, where high strength and precise dimensions are crucial.

One of the key advantages of roll forming machines is their ability to produce large quantities of parts with minimal waste. The continuous process ensures a high production rate, making it an economical choice for mass production. Additionally, the flexibility of the process allows for quick and relatively easy changes in the profile being produced, enabling manufacturers to adapt to evolving market demands.

The roll forming machine has truly revolutionized the way metal products are manufactured. Its precision, efficiency, and versatility have made it an indispensable tool in the modern manufacturing landscape, driving innovation and progress in countless industries.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)