Roll Forming Machine: The Engine of Precision Metal Profiling

Roll forming machines represent one of the most versatile and efficient continuous manufacturing processes in metal fabrication. These specialized machines transform flat metal coils into complex cross-sectional profiles through a progressive bending operation. From construction components and automotive parts to household appliances and industrial equipment, roll forming technology touches nearly every sector of modern manufacturing. This article explores the fundamental principles, applications, and advancements in roll forming machinery.

Fundamental Principles and Process

Roll forming operates on a simple yet sophisticated principle: a continuous metal strip passes through successive pairs of contoured rolls, each performing an incremental part of the total bending operation. This progressive deformation allows for the creation of complex profiles without compromising material integrity.

The standard roll forming line consists of several integrated components:

- Decoiler/Uncoiler – Holds and feeds the metal coil

- Entry Guide – Aligns material entering the forming section

- Roll Forming Station – Multiple stands of precision rollers

- Cut-off System – Hydraulic, servo, or flying cut mechanism

- Run-out Table – Supports and transfers finished product

- Control System – PLC-based operation with HMI interface

Types and Applications

Roll forming machines vary significantly based on their intended application:

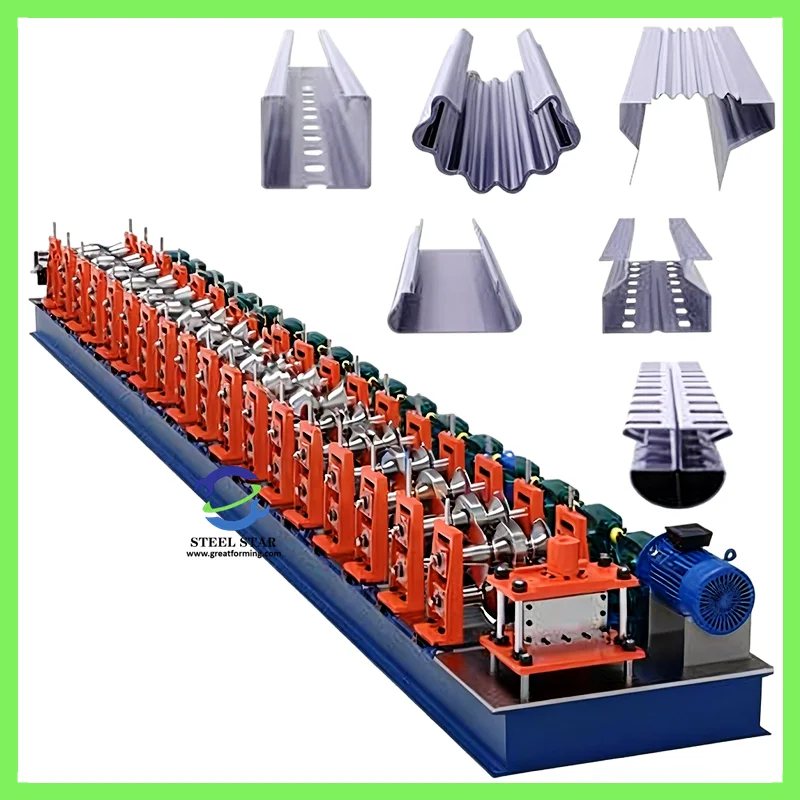

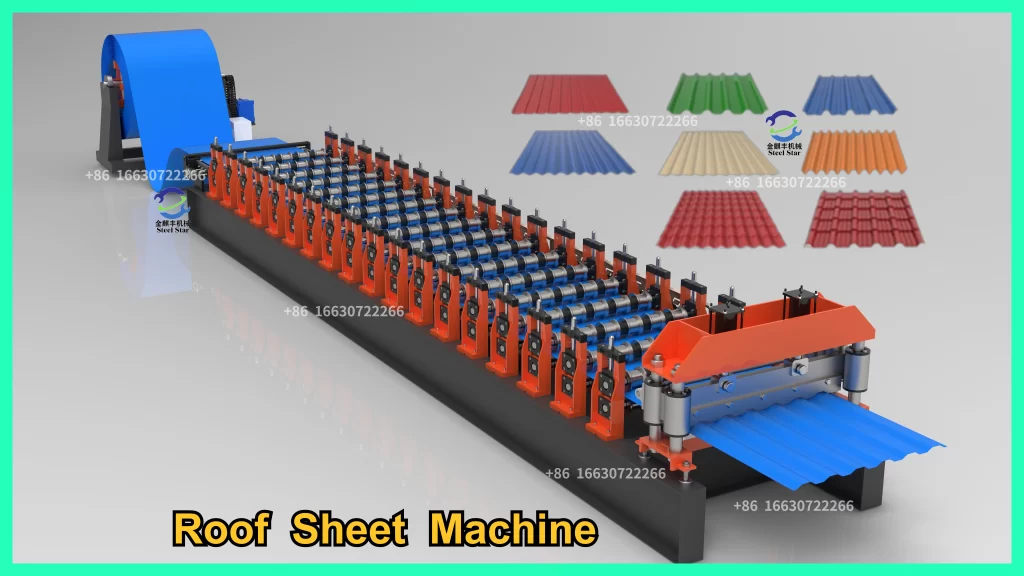

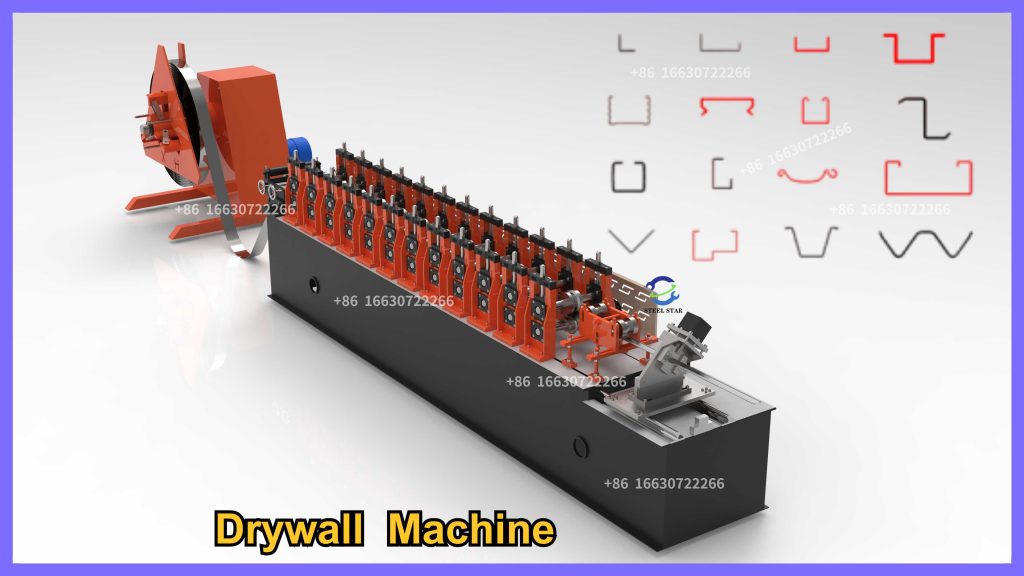

Construction Sector Machines

- Roofing and wall panel lines

- Deck floor forming systems

- Stud and track formers

- Gutter and downspout machines

Industrial Manufacturing

- Automotive trim and structural components

- Appliance cabinet profiles

- HVAC duct and framing systems

- Material handling components

Specialty Applications

- Custom profile formers for unique applications

- High-strength steel formers

- Multi-material compatible systems

Technological Advancements

Modern roll forming machines incorporate several technological improvements:

Precision Control Systems

- Servo-driven technology for synchronization

- Laser measurement for dimensional verification

- Real-time monitoring with data logging capabilities

Flexible Manufacturing Features

- Quick-change roll systems reducing setup time

- Adjustable forming stations for multiple profiles

- Hybrid systems combining roll forming with punching, notching, and welding operations

Material Handling Innovations

- Automated coil loading and feeding systems

- Vision systems for defect detection

- Robotic stacking and packaging integration

Economic and Operational Advantages

Roll forming offers distinct advantages over alternative forming methods:

Production Efficiency

- Continuous operation with speeds up to 200 meters per minute

- Minimal material waste compared to discrete forming processes

- Reduced secondary operations through in-line processing

Quality and Consistency

- Exceptional dimensional accuracy and repeatability

- Superior surface finish protection

- Consistent mechanical properties throughout length

Cost Effectiveness

- High production rates lowering unit costs

- Reduced labor requirements

- Energy efficiency compared to alternative processes

Selection Considerations

Choosing the appropriate roll forming machine requires careful analysis:

Technical Specifications

- Material type, thickness, and width capabilities

- Profile complexity and dimensional requirements

- Production speed and automation needs

Operational Factors

- Floor space and utility requirements

- Maintenance accessibility and support availability

- Operator skill requirements and training

Economic Analysis

- Capital investment versus operational savings

- Return on investment calculations

- Total cost of ownership considerations

Future Trends and Developments

The roll forming industry continues to evolve with several emerging trends:

Digital Integration

- Industry 4.0 connectivity and smart factory integration

- Predictive maintenance through IoT sensors

- Digital twin technology for process optimization

Sustainable Manufacturing

- Energy-efficient drive systems

- Material optimization algorithms

- Recycling-friendly designs

Advanced Materials Processing

- High-strength and advanced alloy capabilities

- Multi-material composite forming

- Precision forming for lightweight structures

Roll forming machines remain indispensable in modern manufacturing, combining centuries-old metalworking principles with cutting-edge technology. Their ability to produce precise, consistent profiles at high volumes makes them economically vital across numerous industries. As manufacturers face increasing demands for customization, efficiency, and quality, roll forming technology continues to adapt and innovate. The future will likely see greater integration with digital systems, expanded material capabilities, and even more flexible production systems, ensuring that roll forming maintains its essential position in the global manufacturing landscape for decades to come.

For businesses considering roll forming equipment, the key lies in thoroughly understanding production requirements, carefully evaluating machine capabilities, and selecting technology that balances current needs with future growth opportunities. With proper selection and implementation, roll forming machinery can provide decades of reliable service while delivering the competitive advantages of efficiency, quality, and cost-effectiveness that modern manufacturing demands.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)