The roll forming machine represents a cornerstone technology in modern automotive manufacturing, enabling the high-volume, precision production of the complex metal profiles that form the structural and functional skeleton of vehicles. From safety-critical chassis components to subtle interior trim, this versatile and efficient process is integral to building lighter, stronger, and more cost-effective automobiles.

Core Function and Strategic Importance

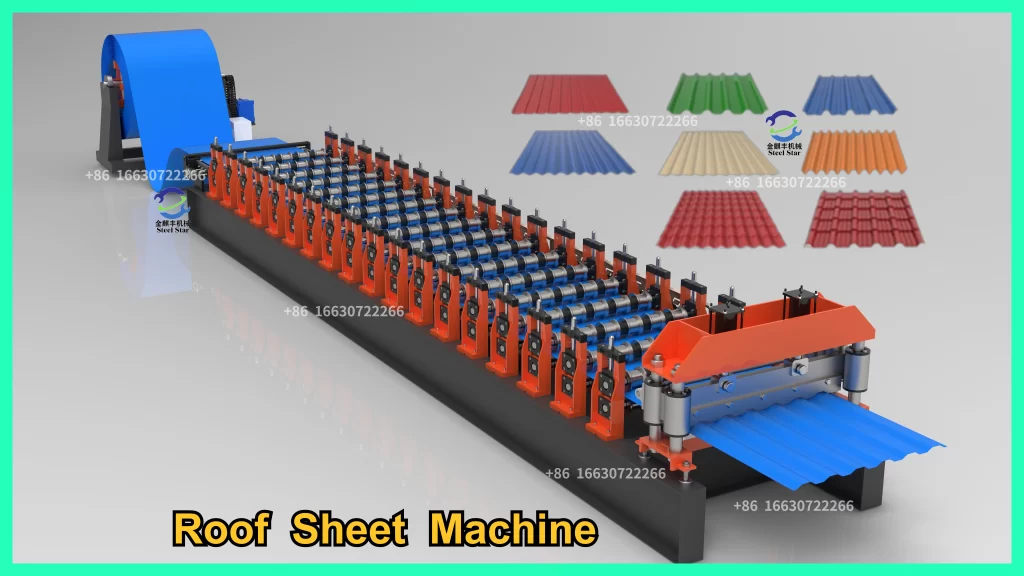

In the automotive industry, roll forming is a continuous, cold-forming process that transforms flat strips of high-strength steel, aluminum, or other alloys into precise, long-length profiles with consistent cross-sections. Unlike stamping, which is ideal for complex, deep-drawn parts, roll forming excels at creating linear components with intricate, uniform geometries. Its strategic value lies in its ability to produce parts with exceptional dimensional accuracy, excellent material properties, and high structural integrity—all at production speeds that match the demanding tempo of automotive assembly lines.

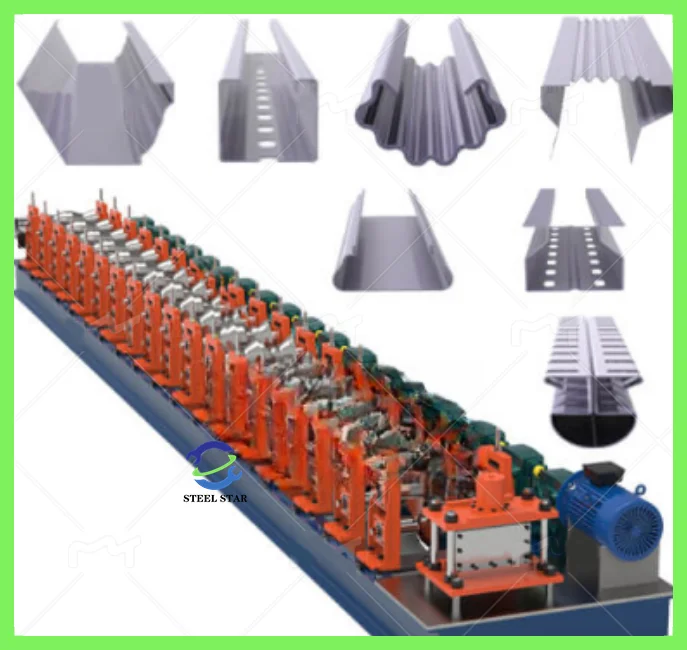

Key Components of an Automotive Roll Forming Line

A system designed for the automotive tier supply chain is a highly integrated and often customized solution:

- High-Precision Decoiler & Entry Guide: Feeds specialty automotive-grade coils with tight tolerances on thickness and coating.

- Pre-Notching and Piercing Stations: Servo-driven units perform precise cutting, punching, or embossing on the flat strip before forming. This is critical for creating mounting holes, weight-reduction cutouts, or attachment features in locations that would be impossible or weak if performed post-forming.

- Multi-Station Forming Mill: The heart of the machine. It features a robust series of roller dies (often 20+ stations) that gradually and precisely bend the metal into the final, often complex, profile. Tooling is engineered to manage springback in advanced high-strength steels (AHSS).

- Post-Forming Operations: May include in-line welding (for closed sections), precision cutting (flying cut-off or die cutting), or automated bending for 3D parts.

- PLC & Vision Control System: A sophisticated control system manages synchronization, stores recipes for different parts, and often integrates laser measurement or vision systems for 100% in-line quality verification of critical dimensions.

Primary Applications in Vehicle Construction

- Structural and Chassis Components: Long rails, side impact door beams (intrusion beams), bumper beams, roof bows, and seat frame components. Roll forming provides superior strength-to-weight ratios for these safety-critical parts.

- Exterior Trim and Sealing Channels: Window frames, beltline moldings, roof drip rails, and door seal channels. The process ensures perfect consistency for fit, finish, and weather sealing.

- Interior Systems: Seat track rails, headrest guides, and instrument panel supports.

- Underbody and Powertrain: Various reinforcement channels, heat shields, and exhaust system components.

- Electric Vehicle (EV) Specific: Battery tray enclosure frames and structural battery pack supports, where precision and integrity are paramount for safety and performance.

Advantages Driving Adoption in Automotive

- Superior Strength and Lightweighting: Cold working strengthens the material at bends. The process allows optimization of profile geometry (e.g., variable cross-sections) to place material only where needed, supporting vehicle lightweighting goals for fuel efficiency and EV range.

- Exceptional Consistency and Quality: Delivers ultra-consistent profiles with minimal tolerance variation, ensuring perfect fit and assembly in automated body shops. This reduces rework and improves overall vehicle quality.

- High Throughput with Low Waste: Operates at high speeds (up to 100+ m/min) with very little material scrap compared to competitive processes, aligning with the high-volume, cost-sensitive nature of auto manufacturing.

- Design Flexibility and Integration: Capable of producing profiles that combine multiple functions (e.g., a structural beam with integrated wiring conduit), reducing part count and assembly steps.

- Material Flexibility: Efficiently processes the latest generation of AHSS, aluminum, and coated materials essential for modern vehicle design.

Technological Synergy with Automotive Trends

The technology is evolving in tandem with industry megatrends:

- Industry 4.0 Integration: Machines are equipped with sensors and data interfaces for predictive maintenance, process monitoring, and full traceability of each produced length—a key requirement for quality assurance in automotive.

- Flexible and Agile Tooling: Quick-change systems allow smaller batch production runs, supporting the trend towards more vehicle platforms and derivatives.

- Hybrid Processes: Integration with robotic welding, adhesive application, or assembly in a single line creates value-added sub-modules ready for just-in-sequence delivery to the assembly line.

The automotive roll forming machine is far more than a simple metal bender; it is a precision engineering system that is fundamental to the modern automotive supply chain. By enabling the mass production of lightweight, high-strength, and complex metal profiles, it directly contributes to the safety, performance, efficiency, and manufacturability of vehicles. As the industry accelerates toward electric, autonomous, and more sustainable vehicles, the precision, efficiency, and material intelligence of advanced roll forming will remain a vital technology in shaping the future of mobility.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)