The Rolling Shutter Forming Machine: Precision in Continuous Motion

In the realm of industrial manufacturing, where efficiency, precision, and material consistency are paramount, the rolling shutter forming machine stands as a specialized and critical piece of equipment. This machine is the engine behind the production of rolling shutters, those ubiquitous security and shading elements used in commercial storefronts, warehouses, garages, and residential properties worldwide. Its operation represents a fascinating application of continuous cold roll forming technology.

Core Function and Principle

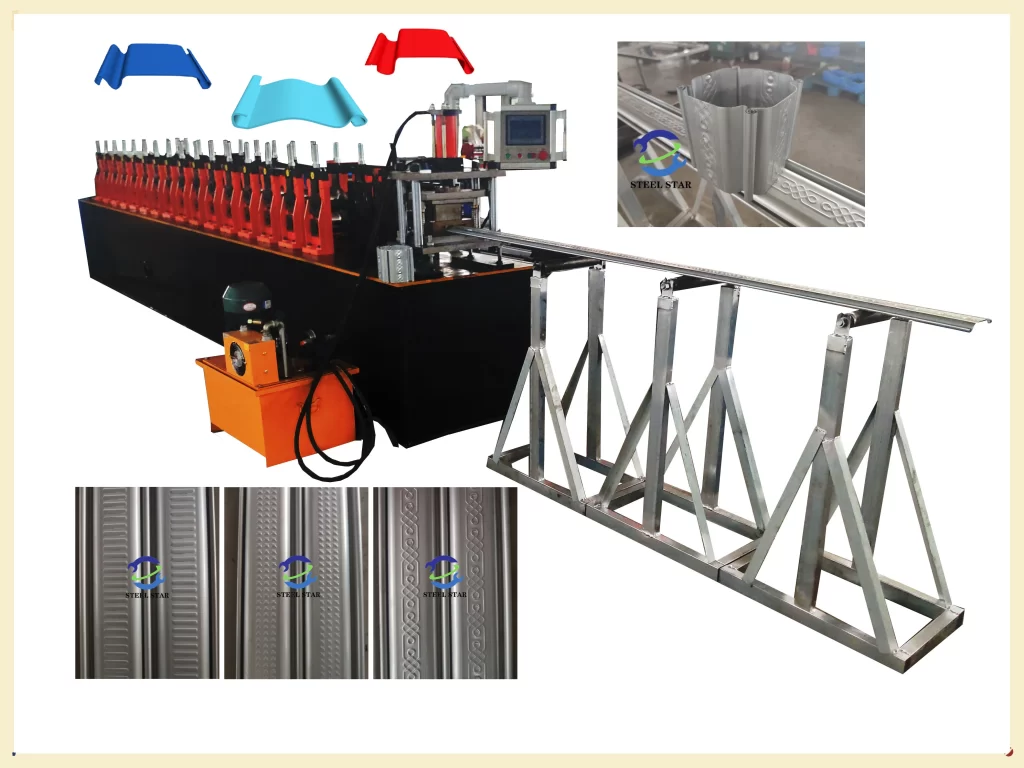

At its heart, a rolling shutter forming machine is a type of cold roll forming line. Its fundamental purpose is to transform a continuous coil of flat metal sheet—typically aluminum, steel, or sometimes PVC-coated materials—into a series of interconnected slats or curtain laths that interlock to form a flexible, yet robust, shutter curtain. Unlike punching or stamping, this is a continuous process. The metal strip is fed from a decoiler, progressively shaped through a series of precisely engineered roller dies.

Each set of rolls, arranged in stations along the machine, incrementally bends the material until it achieves the final, complex cross-sectional profile. This profile is not arbitrary; it is designed with precise interlocking hooks and ribs on each edge. These allow the individual slats to connect seamlessly, forming a cohesive curtain that can be wound around a barrel, providing security, insulation, and light control.

Key Components and Process Stages

A fully integrated forming line comprises several key components:

- Decoiler & Straightener: Holds the master coil and feeds the flat strip into the line, often incorporating a levelling mechanism to ensure flat, consistent material input.

- Pre-punching/Piercing Unit (Optional but common): Before forming, this station may punch necessary holes for the retention bars (which lock slats together) or create perforations for lighter-weight shutters.

- The Roll Forming Mill: The machine’s core. A series of matched roller die stations, mounted on a solid frame, gradually shape the metal. The number of stands depends on the profile complexity.

- Cut-off System: As the fully formed profile exits the final rolls, a precise cutting mechanism—usually a flying cut-off saw or hydraulic shear—cuts the continuous strip into predetermined slat lengths without stopping the line.

- Run-out Table & Stacker: Handles and collects the finished slats for subsequent assembly into the complete shutter curtain.

Technical Advantages and Design Considerations

The use of roll forming offers significant advantages for shutter production:

- High-Speed, Continuous Output: Enables mass production with consistent quality, crucial for meeting large-scale demand.

- Material Strength: The cold-working process can increase the yield strength of the metal along the bends.

- Consistent Dimensional Accuracy: Once the roller dies are set, every slat produced is identical, ensuring perfect interlock and smooth operation.

- Versatility: Modern machines can be equipped with quick-change roll systems, allowing a single line to produce different slat profiles and widths, enhancing flexibility.

Critical design considerations for the machine include the geometry of the interlocking mechanism, which must balance security strength with smooth rolling action. The precision of the roller dies is non-negotiable, as any imperfection is replicated across thousands of slats. Furthermore, machine rigidity is vital to maintain alignment and prevent deflection under the high torsional forces of forming.

Evolution and Technological Integration

Today’s rolling shutter forming machines are far more sophisticated than their predecessors. Integration with CNC (Computer Numerical Control) and PLC (Programmable Logic Controller) systems allows for precise control over speed, cut length, and sequencing. Advanced servo-driven cut-off systems provide exceptional length accuracy. Some lines also incorporate in-line painting or powder coating, or automated stacking and packaging, creating a truly continuous, end-to-end production cell.

The rolling shutter forming machine is a brilliant example of applied mechanical engineering solving a specific manufacturing need. It transforms a simple coil of metal into a functional, durable, and essential building component through a process of incremental, precision deformation. Its continuous, high-speed operation underpins the global availability of rolling shutters, making it an unsung hero in the fabrication of modern architectural elements for security, privacy, and energy efficiency. As material science and automation advance, these machines will continue to evolve, producing ever more sophisticated and reliable products with greater efficiency.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)