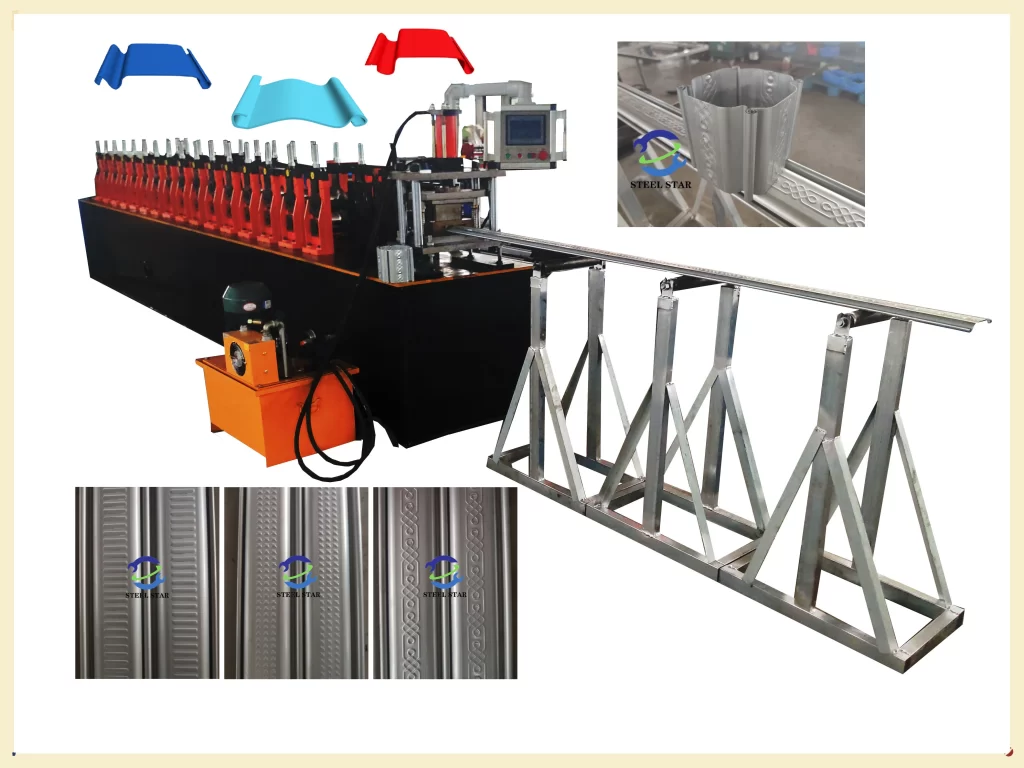

A Rolling Shutter Roll Forming Machine is a specialized industrial system designed for the continuous, automated production of metal slats—the interlocking strips that form the curtain of commercial and residential rolling shutters. These machines are critical for manufacturing security doors, fire-resistant barriers, and insulated closures used in storefronts, warehouses, garages, and industrial facilities worldwide.

Core Function and Product

The machine transforms pre-painted galvanized steel or aluminum coils into precise, interlocking slat profiles through a continuous cold roll forming process. Each slat features engineered interlocks (tongue-and-groove or hook-and-channel designs) along its edges, allowing the assembled curtain to coil smoothly around a barrel while providing structural rigidity, security, and often thermal or acoustic insulation when filled with foam.

Integrated Production Line Components

A complete rolling shutter slat production line is an integrated system combining several key stations:

- Decoiler & Straightener: Holds and feeds the metal coil into the line, ensuring flat, consistent material input.

- Pre-Punching Station (Critical): A servo-driven punching unit perforates the flat strip with precisely spaced holes. These holes serve multiple purposes: reducing weight, allowing for the injection of polyurethane foam for insulation, and providing mounting points for guide brackets and end locks.

- Main Roll Forming Section: The heart of the machine. A series of contoured roller dies progressively shape the flat, punched strip into the final slat profile. This includes forming the complex interlocking edges and the curved outer face of the slat in a single pass. Precision here ensures smooth interlocking and consistent coil diameter.

- Foam Injection System (Optional for Insulated Shutters): For insulated shutters, the formed slat passes through a chamber where liquid polyurethane is injected into the hollow profile. It expands and cures rapidly, creating a solid, lightweight foam core that provides excellent thermal and acoustic properties.

- Post-Forming & Cutting: The continuous slat is guided through a calibration section to ensure straightness. A high-speed, servo-controlled flying cut system then shears it to precise, pre-set lengths without stopping the line.

- Output Conveyor: Gently transports the finished slats to a stacking or packaging area.

Technical Advantages and Innovations

- High-Speed, Consistent Production: Capable of producing slats at speeds of 15-40 meters per minute, ensuring uniformity in every batch—a critical factor for reliable shutter operation and assembly.

- Complex Profile Fabrication in One Pass: Integrates punching and forming into a seamless process, handling intricate geometries that would be inefficient or impossible with separate operations.

- Integrated Insulation Manufacturing: The combination of roll forming with in-line foam injection creates a finished, insulated slat as a single composite product, streamlining production.

- Material Efficiency and Strength: The cold-forming process increases strength through work-hardening. Precise punching and cutting minimize scrap.

- Flexibility: Quick tooling changes allow a single machine to produce various slat widths, thicknesses, and interlock designs for different security ratings and aesthetic requirements.

Industry Impact and Applications

The slats produced are essential for:

- Commercial Security: Storefront grilles and security shutters for retail spaces.

- Industrial & Warehouse Closures: Large-scale sectional doors and fire-rated rolling barriers.

- Residential Garage Doors & Security Shutters: Providing safety, insulation, and noise reduction.

- Specialized Environments: Cleanrooms, cold storage, and noise-sensitive facilities utilizing insulated variants.

This machinery enables manufacturers to produce high-performance, customizable rolling shutter systems that meet stringent standards for security (e.g., resistance to manual attack), insulation (U-values), and fire resistance.

The Rolling Shutter Roll Forming Machine is a paradigm of integrated, value-added manufacturing. It transcends simple metal shaping by combining precision perforation, complex profile forming, and material compounding (with foam) into one efficient, automated line. This technology empowers manufacturers to meet the growing global demand for high-performance building envelope solutions that provide security, energy efficiency, and operational reliability. As building codes and security requirements evolve, this machinery remains fundamental in fabricating the dynamic closures that protect assets and insulate spaces worldwide.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)