In the vast landscape of construction and industrial manufacturing, few machines operate with such a direct and visible impact on our built environment as the roof panel forming machine. This robust, continuous roll-forming apparatus is the unsung hero behind the sleek, protective shells of warehouses, airports, stadiums, agricultural buildings, and residential homes. More than just a metal bender, it is a sophisticated engineering system that transforms flat coils of steel, aluminum, or other metals into high-strength, weather-tight, and often aesthetically pleasing roof panels with remarkable speed and precision.

1. The Core Principle: Continuous Roll Forming

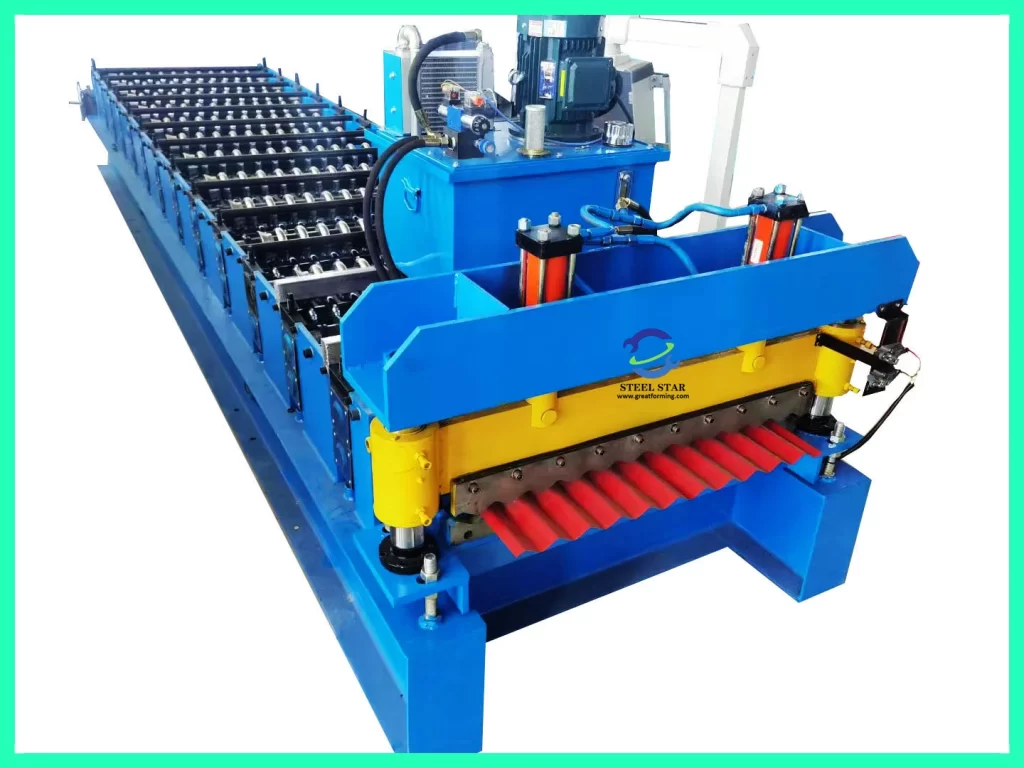

At its heart, a roof panel forming machine operates on the principle of continuous cold roll forming. Unlike stamping or pressing, which uses discrete cycles, roll forming is a progressive, linear process. A large coil of metal (the “mother coil”) is loaded onto an unwinding mandrel at the start of the line. This flat strip is then fed through a series of precisely engineered roll stations, typically arranged in tandem.

Each station consists of a set of hardened steel rolls, mounted on horizontal shafts. The geometry of these rolls incrementally bends the metal strip by fractions of a millimeter at each pass. The first few stations make broad, preliminary bends, while subsequent stations refine the shape, adding lock seams, stiffening ribs (or “ribs”), and the final profile. The metal is formed plastically at room temperature, work-hardening it in the process, which enhances its stiffness without adding weight. By the time the strip exits the final roll station, it has been transformed into a continuous, kilometers-long panel with a complex cross-section, ready to be cut to length and assembled on a roof.

2. Key Components of a Modern Forming Line

A complete roof panel forming line is a symphony of integrated components:

- Decoiler & Entry Guide: Holds and feeds the mother coil, often with automatic stitching to join coils end-to-end for non-stop production.

- Accumulator: A vital loop system that stores a reserve of material, allowing the decoiler to stop and load a new coil while the forming section continues running uninterrupted.

- Pre-Punching/Notching Unit (Optional): A CNC-controlled press that punches holes for screws, vents, or creates custom notches before the metal is formed, a critical feature for complex architectural panels.

- Roll Forming Mill: The machine’s core. It houses the series of roll stations, driven by a powerful motor via gearboxes and drive shafts. Modern mills are modular, allowing for quick profile changes.

- Cut-Off System: A high-speed flying cut-off machine, usually hydraulic or servo-electric, that shears the continuous panel to pre-programmed lengths without stopping the line. Laser cut-offs are emerging for complex, burr-free cuts.

- Exit Table & Stacker: Supports and conveys the finished panels, organizing them into neat, banded stacks for shipment.

- Control System: The brain of the operation. A centralized PLC (Programmable Logic Controller) with an HMI (Human-Machine Interface) synchronizes all components, controls speed, length, punching patterns, and monitors diagnostics.

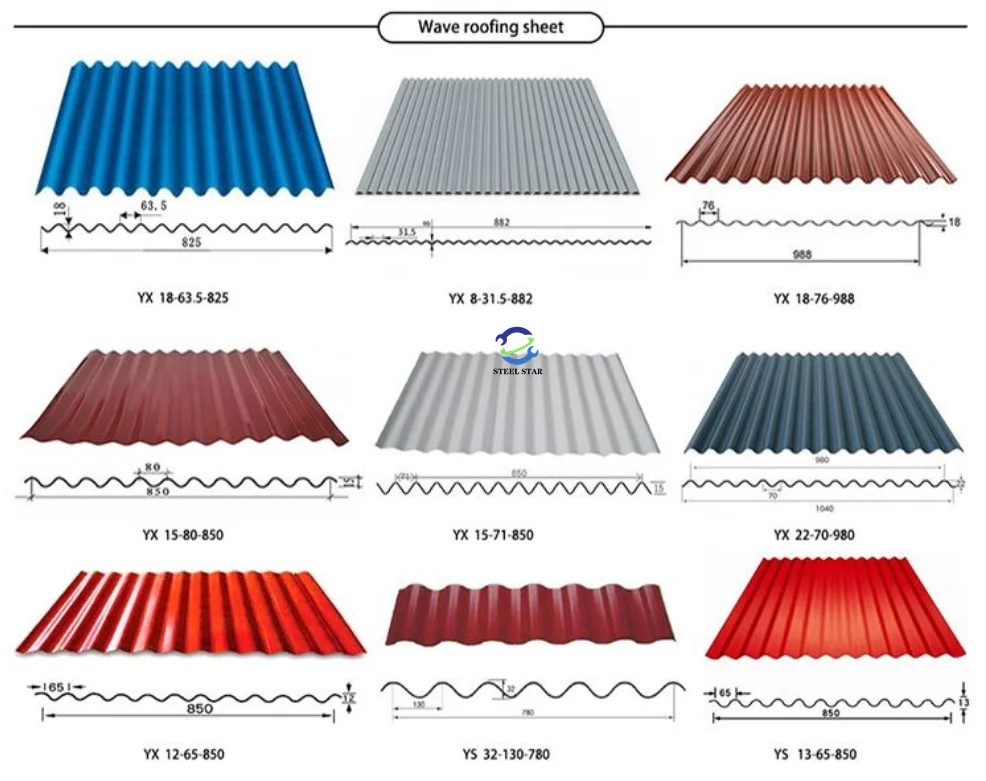

3. The Science of the Profile: More Than Just Shape

The design of the panel profile is where engineering meets performance. Each ridge, valley, and rib serves a purpose:

- Structural Integrity: Major ribs (like trapezoidal ribs) act as miniature I-beams, providing exceptional span capability and load resistance (for snow, wind, and maintenance workers).

- Water Management: Integrated drainage channels, steep slopes, and capillary breaks direct water efficiently off the roof.

- Sealing Systems: Critical for standing seam roofs. Panels are formed with male and female seams that are mechanically seamed together on-site using a mobile seamer, creating a watertight, concealed-fastener roof that can thermally expand and contract.

- Aesthetics: Profiles can mimic traditional tiles, shakes, or shingles, offering the durability of metal with the visual appeal of other materials.

The machine must be meticulously engineered to form these features consistently, accounting for springback—the metal’s tendency to slightly revert after bending—and maintaining tolerances often within fractions of a millimeter over the panel’s entire length.

4. Types and Applications

Machines are often categorized by the profile they produce:

Through-Fastened Panel Machines: Form panels with exposed fasteners, typically used for cost-effective agricultural, industrial, and utility buildings.

Standing Seam Machines: Produce high-end panels with raised, field-seamed edges. The gold standard for commercial and architectural applications due to longevity, weathertightness, and thermal performance.

Tile/Shingle Profile Machines: Create metal panels that replicate the look of clay tile, wood shake, or slate, popular in residential and historic renovation markets.

Custom/Architectural Panel Machines: Highly flexible systems capable of producing complex, often one-off profiles for iconic buildings, with advanced pre-punching and cutting capabilities.

5. The Evolution: Automation and Intelligence

The technology is not static. The latest advancements are revolutionizing the industry:

- Servo-Electric Drive Systems: Replacing hydraulic systems for greater precision, energy efficiency, quieter operation, and lower maintenance.

- Industry 4.0 Integration: Machines equipped with IoT sensors for predictive maintenance, real-time monitoring of roll wear and forming pressures, and data collection for production analytics.

- Advanced Software: 3D simulation software models the entire forming process digitally before a single roll is machined, optimizing station design and predicting material stress.

- Hybrid Lines: Integrating secondary processes like insulation foaming, laminated film application, or even painting in-line with forming.

The roof panel forming machine is a quintessential example of applied industrial engineering. It takes a raw, mundane material and, through a process of controlled deformation, converts it into a vital component of shelter and architecture. Its continuous hum in factories worldwide is the sound of efficiency, translating engineering designs into durable, reliable, and often beautiful building envelopes. As construction demands evolve towards greater sustainability, speed, and architectural ambition, the roof panel forming machine will continue to adapt, its rolls shaping not just metal, but the very skyline of our future. From safeguarding aircraft in hangars to sheltering families in homes, it remains an indispensable tool in the ongoing task of building and protecting our world from the top down.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)