Roof Roll Forming Machine: Engineering the Skyline, One Panel at a Time

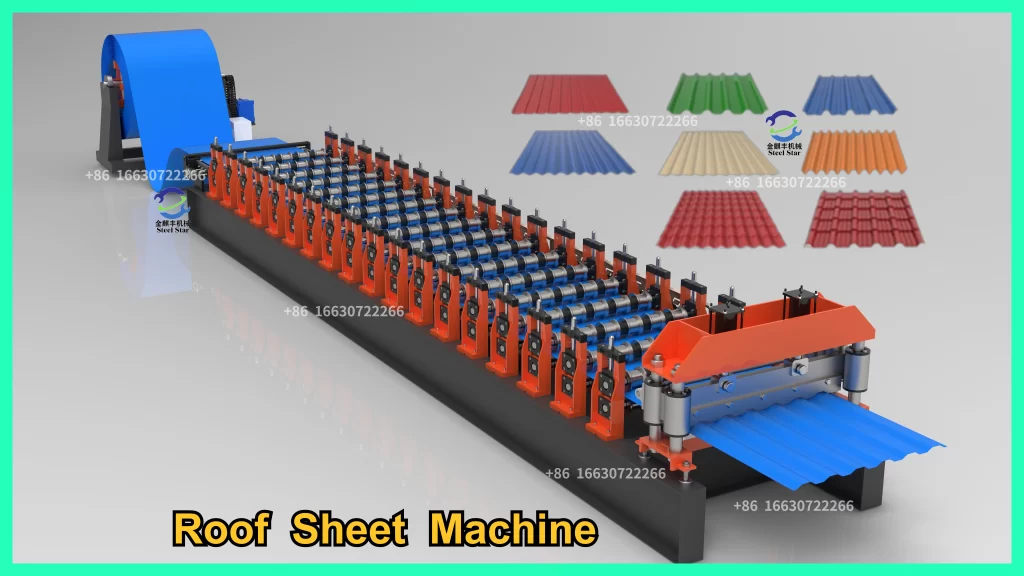

In the realm of modern construction, efficiency, durability, and design flexibility are paramount. At the forefront of meeting these demands for building envelopes is the Roof Roll Forming Machine—a sophisticated piece of industrial equipment that transforms flat metal coils into high-strength, consistent, and aesthetically pleasing roofing panels with remarkable speed and precision. This machine is the cornerstone of the metal roofing industry, enabling the creation of durable shelters for everything from residential homes to vast industrial complexes.

Core Function and Principle

A Roof Roll Forming Machine is a type of cold-forming equipment. Its fundamental operation is continuous and efficient:

- A coil of raw material (typically pre-painted galvanized steel, aluminum, or zinc-aluminum alloy) is loaded onto an uncoiler.

- The metal strip is fed progressively through a series of paired roller dies (stations), each performing an incremental part of the bending process.

- With each station, the flat strip gradually takes on the complex cross-sectional profile of the final roofing panel.

- The fully formed panel is then cut to a precise length by a flying cut-off system without stopping the line, and is automatically stacked for shipment.

This cold-forming process work-hardens the metal along the bends, enhancing the panel’s stiffness without compromising its corrosion-resistant coatings.

Key Components of the Machine

A complete roll forming line integrates several critical subsystems:

- Decoiler/Uncoiler: Holds the heavy metal coil and feeds it into the machine under controlled tension.

- Feeding & Leveling Unit: Ensures the strip is perfectly flat and aligned before entering the forming rolls, critical for profile consistency.

- Roll Forming Station: The heart of the machine. It consists of a series of shaft-mounted, hardened steel roller dies mounted in a robust frame. The design and precision machining of these rolls determine the final panel profile.

- Cut-Off System: Usually a hydraulic or servo-mechanical flying cut device that cleanly shears the moving panel to pre-set lengths.

- PLC Control System: The “brain” of the operation. A Programmable Logic Controller allows operators to input parameters (length, quantity, speed), monitors the entire process, and ensures synchronization of all components.

- Output Table & Stacker: Gently receives the finished panels and organizes them into neat bundles for handling.

Profile Versatility and Applications

The true power of these machines lies in their flexibility. By changing the set of roller dies, a single machine can produce a wide array of roof panel profiles, each serving specific functional and aesthetic purposes:

- Corrugated Panels: The classic, versatile profile known for its strength and simple installation.

- Standing Seam Roof Panels (SSR): The premium choice for commercial and architectural projects. These panels feature raised, interlocking seams that are mechanically seamed on-site, creating a watertight, fastener-free roof surface that allows for thermal expansion.

- Tile-Effect Profiles: Mimic the appearance of traditional clay or concrete tiles while offering the lightweight durability of metal.

- Batten Cap & Architectural Panels: Used for specialized commercial and residential designs.

These panels are essential for residential roofing, warehouses, factories, agricultural buildings, airports, and sports stadiums.

Technological Advancements and Benefits

Modern roof roll forming machines embody significant technological progress:

- High-Speed Servo Technology: Enables faster production speeds (often 30-100 meters per minute) and ultra-precise cut-to-length accuracy, minimizing material waste.

- In-Line Punching and Notching: Integrated servo-punching units can add custom holes, vents, or notches during the forming process in a single pass.

- Automatic Profile Changeovers: Advanced systems allow for quicker switching between different panel profiles, enhancing flexibility for small-batch production.

- Superior Consistency & Quality: Once calibrated, the machine produces kilometer-long runs of panels with identical geometry, ensuring predictable performance and ease of installation.

- Material Efficiency: The process generates minimal scrap compared to other forming methods, optimizing raw material use.

The Roof Roll Forming Machine is more than just a factory tool; it is an enabler of modern architecture and sustainable construction. By combining mechanical engineering, precision tooling, and digital control, it efficiently produces roofing systems that offer longevity, weather resistance, and energy efficiency. As the global construction industry continues to prioritize resilient and cost-effective building solutions, the evolution of these machines—towards greater automation, intelligence, and versatility—will continue to shape the skylines of the future, ensuring that the shelters over our heads are both strong and smart.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)