The Roof Roll Forming Machine Factory: Where Innovation Meets the Skyline

The modern roof roll forming machine factory is far more than an assembly floor; it is a specialized hub of engineering excellence, where precision, durability, and architectural ambition are forged into industrial machinery. These factories produce the equipment that, in turn, creates the protective shells of our buildings—the standing seam panels, trapezoidal sheets, and classic corrugated roofs that define skylines worldwide.

The Core Mission: Building the Machines That Build Roofs

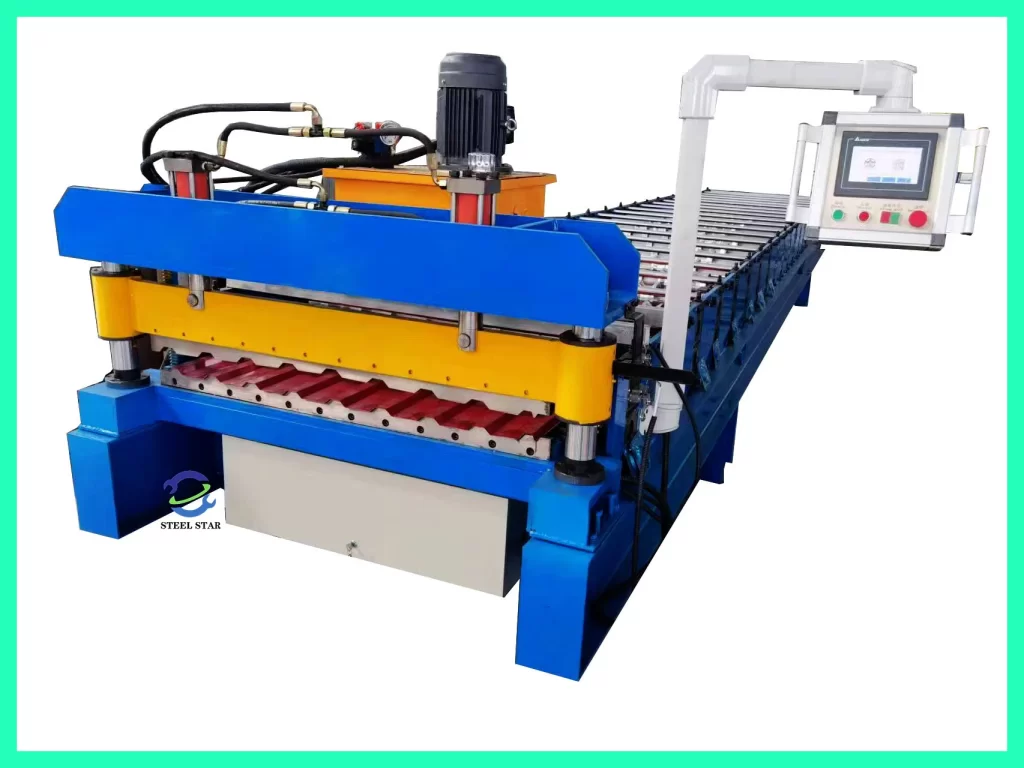

A roof roll forming machine factory is dedicated to designing, manufacturing, and supporting automated production lines that continuously shape metal coils into specific roof profile sections. Their primary product is a complete system, typically comprising a decoiler, a precision roll forming mill with a specific sequence of roller dies, a cutting unit, and a discharge table. The factory’s expertise lies in translating complex architectural profiles into robust, reliable, and efficient mechanical systems.

Inside the Factory: A Symphony of Specialized Processes

- Design & Engineering Hub: The process begins with CAD/CAM and simulation software. Here, engineers design the heart of the machine: the roll tooling. Each set of hardened steel rollers is meticulously calculated to progressively form the metal without stretching or distorting it. The factory’s proprietary tooling designs are often its key competitive advantage.

- Precision Machining Center: This is where raw steel blocks are transformed into precision components. Using CNC lathes, milling machines, and grinding equipment, factory technicians manufacture the roller dies, gearboxes, shafts, and structural frames. Tolerances are measured in hundredths of a millimeter to ensure flawless profile consistency.

- Assembly & Integration Floor: Machined components converge here. The roll forming mill is assembled like a vertical puzzle, with each stand of rollers aligned perfectly. The mechanical system is integrated with hydraulic, pneumatic, and electrical systems. The cutting unit (flying shear or hydraulic cutoff) is synchronized with the forming speed.

- Control Systems & Electrics Lab: Modern machines are driven by sophisticated PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) systems. In this area, control panels are wired, programmed, and tested to manage speed, length, count, and diagnostics for fully automated operation.

- Testing & Run-Off Area: Before shipment, every machine undergoes a rigorous “run-off” or commissioning test. Using real metal coils, the factory technicians and the client’s representatives verify profile accuracy, production speed, cut-length precision, and overall system stability. This phase is critical for quality assurance.

Product Portfolio: Catering to a Diverse Market

A leading factory typically offers a range of machines, reflecting diverse market needs:

- Standing Seam Roof Machines: High-precision machines for forming panels with integrated, concealed clip systems, enabling thermal expansion and superior weather tightness.

- Trapezoidal Roof Panel Machines: For producing strong, span-capable profiles widely used in industrial and commercial buildings.

- Corrugated Roof Sheet Machines: For classic, cost-effective profiles used in agricultural and utility buildings.

- Tile Effect & Shingle Machines: For producing metal panels that mimic traditional clay or concrete tiles, offering durability with aesthetic appeal.

- Integrated Systems: Complete lines that include automated embossing, pre-punching, or even inline insulation attachment.

The Hallmarks of a Leading Factory

- Engineering Depth: The ability to design complex tooling for new, custom profiles in-house.

- Build Quality & Robustness: Use of high-grade materials (e.g., alloy steel for rollers) and heavy-duty construction for 24/7 industrial operation.

- Technological Integration: Offering features like servo-driven cutting, quick-change tooling systems, IoT-enabled monitoring, and compatibility with Building Information Modeling (BIM) data.

- Comprehensive Support: Providing detailed installation guidance, operator training, readily available spare parts, and global technical service. The factory’s role extends far beyond the sale.

- Customization Capability: The flexibility to modify standard machines for unique client requirements regarding material type (steel, aluminum, zinc), thickness, width, and production speed.

Global Impact and Industry Drivers

These factories are enablers of modern construction. Their machines produce roofs that are:

- Rapid to Install: Large panels cover area quickly.

- Extremely Durable: Long-lasting with minimal maintenance.

- Energy Efficient: Compatible with solar integration and cool-roof coatings.

- Sustainable: Made from recyclable materials, with production generating little waste.

Factory innovation is driven by demands for faster installation speeds, more complex architectural forms, and the need for energy-efficient building envelopes.

A roof roll forming machine factory operates at the intersection of heavy industry and architectural artistry. It is a place where mechanical engineering expertise is applied to solve practical challenges of shelter, weatherproofing, and aesthetics. By building the machines that form the roofs over our heads, these factories play a foundational, though often unseen, role in shaping the built environment. Their continued innovation directly contributes to safer, more efficient, and more visually compelling structures around the globe. They don’t just manufacture machinery; they manufacture the capability to build better.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)