Roof Sheet Machine: Innovation and Global Influence of China’s Manufacturing

Roof Sheet Machine, also known as roll forming machine, is a core equipment in modern construction that transforms metal coils into standardized, high-strength roof panels. By virtue of continuous roll forming technology, it has become an indispensable part of industrial plants, warehouses, public buildings and residential constructions, reshaping the efficiency and quality of roofing projects worldwide. Among global suppliers, China’s Roof Sheet Machine stands out with technical upgrades, policy support and cost advantages, evolving into a key force driving the industry’s development.

Core Principles and Application Value of Roof Sheet Machine

Roof Sheet Machine operates on the principle of incremental continuous forming, realizing efficient production of roof panels through a streamlined workflow.

Working Mechanism

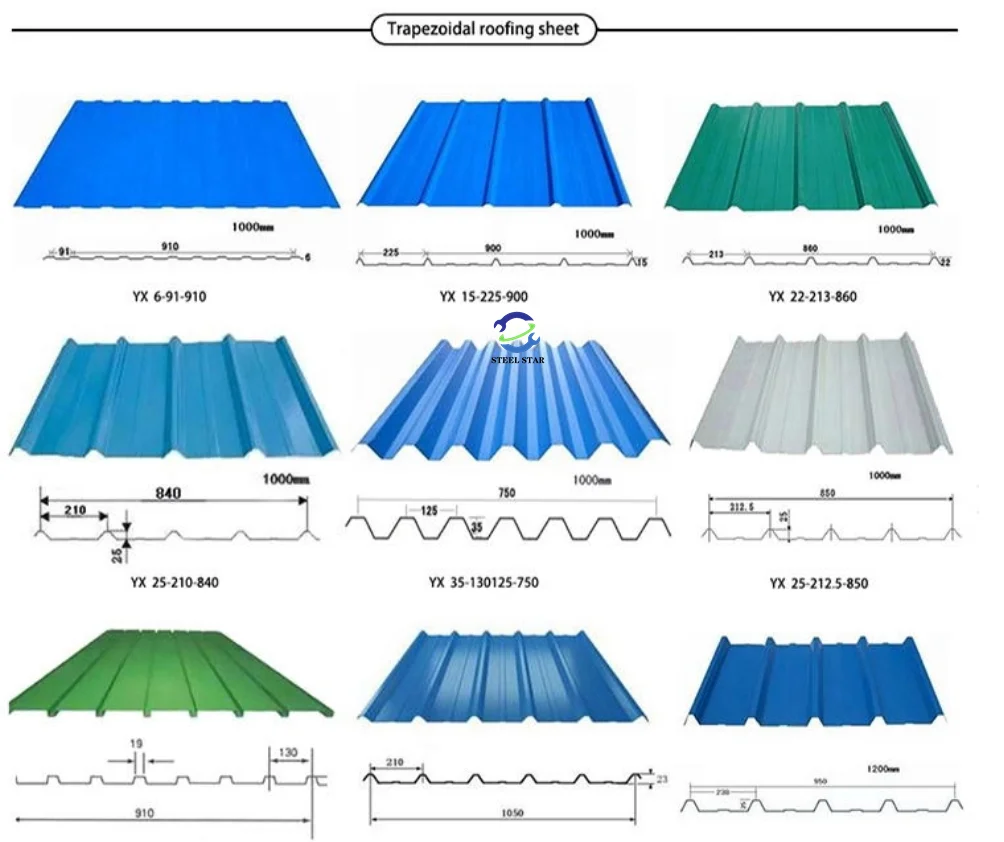

The production process starts with placing metal coils (such as galvanized steel, aluminum or coated alloys) on a decoiler for stable unwinding. The metal strip then passes through a leveling unit to eliminate defects, ensuring flatness before forming. Next, it enters multiple sequential forming stations, where each set of precision rollers gradually bends the strip into desired profiles—including corrugated, trapezoidal or tile patterns. Finally, a hydraulic or pneumatic cutting system trims the formed sheet to preset lengths, with the entire process controlled by PLC systems for automation and accuracy.

Core Advantages

High production efficiency: Advanced models can achieve speeds of 40-50 meters per minute, far exceeding traditional manual processing.

Superior product consistency: Precision roller design and automated control ensure uniform thickness and profile of each roof sheet.

Material and cost savings: The cold roll forming process minimizes material waste, while automation reduces labor input significantly.

Strong adaptability: It can process metal coils of 0.3-0.8mm thickness and customize profiles according to project requirements, suitable for various construction scenarios.

Technical Upgrades and Product Evolution

China’s Roof Sheet Machine has shifted from traditional mechanical models to intelligent, automated products. In 2024, the market penetration rate of fully automatic models exceeded 54.3%, and high-end CNC servo-type equipment accounted for 43.05% of the market. Leading manufacturers have launched intelligent models with remote monitoring, fault diagnosis and parameter self-adaptive adjustment functions, whose shipments increased by 23.7% year-on-year. Key components such as 45# steel rollers with chrome plating and balanced correction shafts enhance equipment durability and product surface quality, avoiding paint scratches on colored steel sheets.

Future Trends of Roof Sheet Machine Industry

The global Roof Sheet Machine industry is moving towards intelligence, greenization and customization, with China playing a pivotal role in promoting this transformation. Future development will focus on three directions: deeper integration of BIM technology and intelligent manufacturing systems to enhance equipment’s data analysis and predictive maintenance capabilities; optimization of energy-saving designs to adapt to the production of recycled metal materials; and expansion of application scenarios in new energy projects such as photovoltaic supporting plants.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)