Roofing Sheet Manufacturing Machines: Engineering the Backbone of Modern Shelter

Few building components are as ubiquitous—and as easily overlooked—as the humble roofing sheet. From the corrugated galvanized iron that shelters rural workshops to the standing seam panels enclosing airports and stadiums, profiled metal roofing has become the global standard for durability, affordability, and speed of installation. Behind every roll of formed roofing lies a machine that is itself a marvel of precision engineering: the roofing sheet manufacturing line.

These machines, which transform flat steel or aluminum coils into fully profiled, cut-to-length roofing panels, represent a mature yet continuously evolving technology. For entrepreneurs considering entry into the building materials sector, established manufacturers seeking to expand product lines, or contractors aiming to integrate backward into production, understanding the capabilities, configurations, and economics of roofing sheet machines is essential. This article provides a comprehensive examination of the equipment, processes, and market dynamics that define this critical manufacturing sector.

The Evolution of Roofing Production

The history of metal roofing production is a story of progressive mechanization. Early corrugating lines of the nineteenth century used paired rolls turned by hand or water power. By the mid-twentieth century, stand-alone roll formers required separate shears, stackers, and coil handling equipment, with operators moving material between stations. The 1980s brought integrated production lines, and the 1990s introduced CNC controls. Today, a modern roofing sheet machine is a continuous, synchronized system that converts coil to finished, stacked product with minimal human intervention.

This evolution has democratized production. A single operator can now produce more roofing in one hour than a team of ten could produce in a day fifty years ago. The barrier to entry has shifted from physical labor to technical knowledge and capital availability.

Core Machine Types and Configurations

Roofing sheet manufacturing machines are not monolithic; they are tailored to specific product categories and production volumes. Understanding these distinctions is the first step in equipment selection.

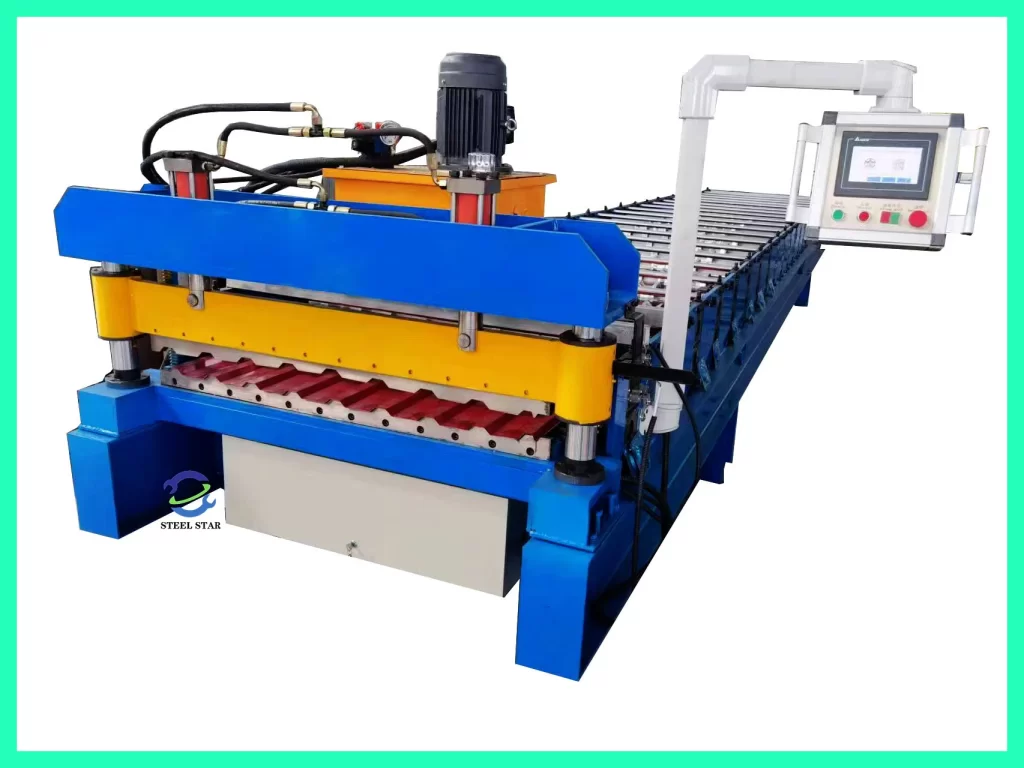

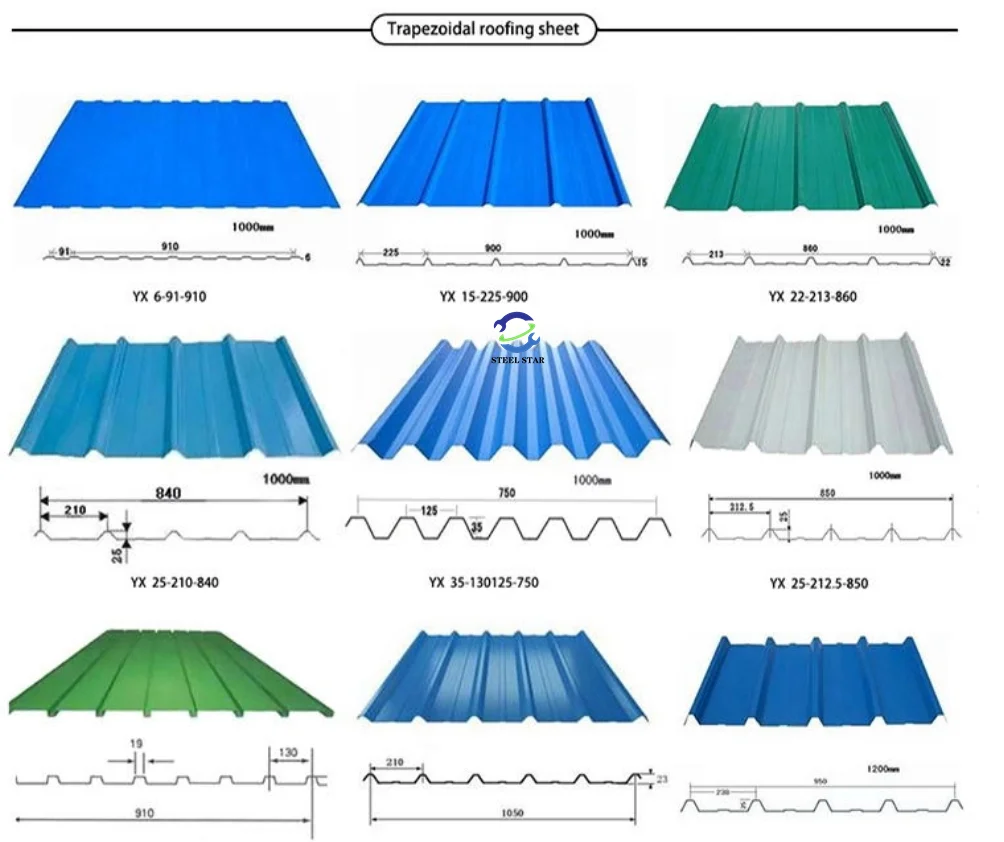

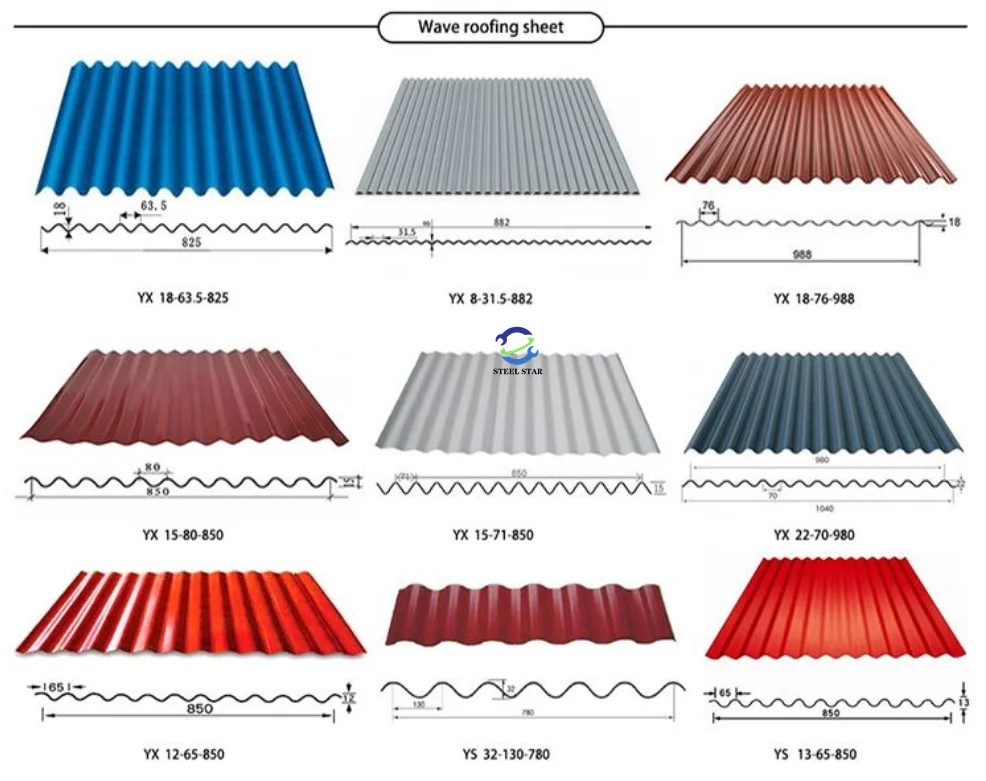

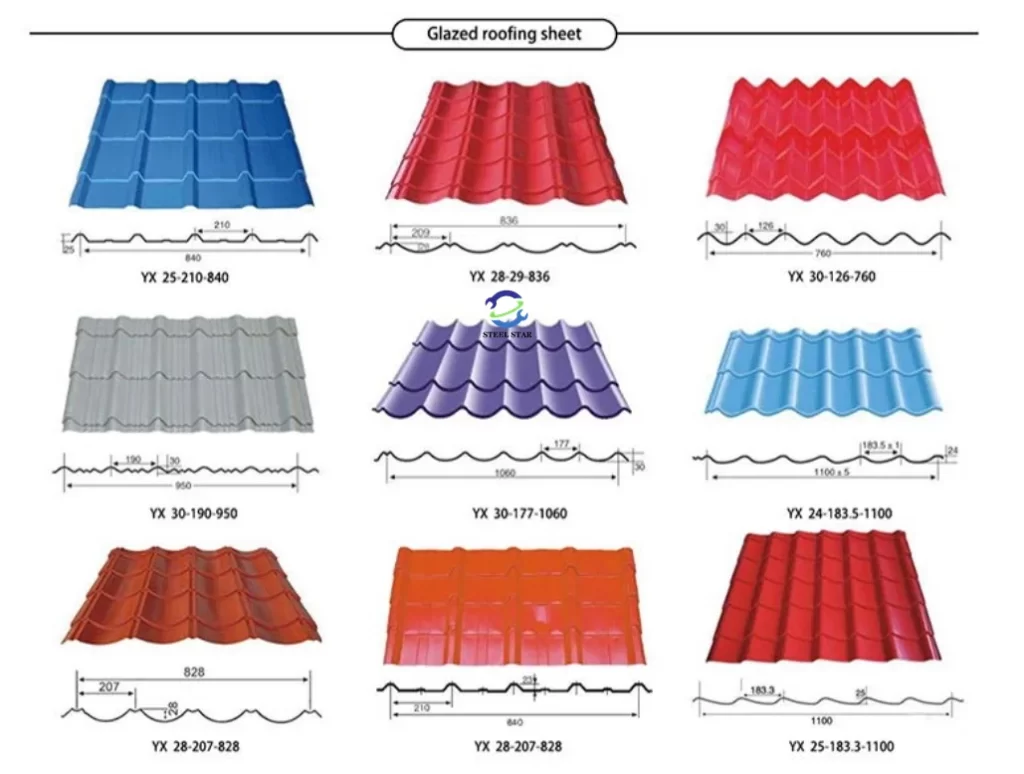

Single-Profile Roll Formers are the workhorses of the industry. These dedicated lines produce one specific panel profile—traditional corrugated, trapezoidal, ribbed, or standing seam—at speeds ranging from 15 to 40 meters per minute. Tooling is fixed to the profile geometry. Changeovers to different profiles require roll set replacement, a process that can take two to four hours. Single-profile machines are ideal for manufacturers focused on high-volume production of standard panels.

Multi-Profile or Quick-Change Machines address the need for flexibility. These systems feature interchangeable roll cartridges or, in the most advanced configurations, servo-adjustable rolls that can alter profile dimensions under computer control. A manufacturer can produce corrugated sheets in the morning, trapezoidal sheets in the afternoon, and standing seam panels in the evening. The capital cost is substantially higher than single-profile lines, but for job shops and regional suppliers serving diverse markets, the flexibility justifies the investment.

Portable or Mobile Roofing Machines represent a distinct category. Mounted in shipping containers or trailers, these machines are deployed directly to construction sites. Coils are fed into one end of the container; finished panels emerge at the other, cut to exact site dimensions. Mobile production eliminates transportation of long panels, reduces damage during transit, and enables just-in-time installation. These systems are widely used in commercial and industrial roofing, as well as in disaster recovery and remote construction.

Key Components and Subsystems

A complete roofing sheet production line is an assembly of interdependent modules, each critical to final product quality.

The Decoiler and Coil Handling System initiates the process. For roofing production, decoilers must accommodate coil weights from 2 to 10 tons, with mandrels sized to standard inner diameters. Motorized decoilers with loop control are standard; double-end configurations are common in high-volume operations. Coil cars, loading arms, and peeler units expedite setup and reduce operator strain.

The Roll Forming Mill is the heart of the line. A typical roofing mill contains 12 to 24 forming stations, each comprising a pair of contoured rolls that incrementally shape the flat strip. Roll materials range from hardened tool steel for long production runs to chrome-plated or even urethane-coated rolls for prepainted or sensitive surfaces. Precision shafting, heavy-duty bearings, and rigid mill frames prevent deflection under load—essential for maintaining consistent panel dimensions.

The Cutting System distinguishes professional-grade lines from hobbyist equipment. Hydraulic or servo-electric flying shears cut panels to length without stopping the material flow. The shear travels with the moving panel, makes a clean, burr-free cut, and returns to home position in milliseconds. Cut length accuracy of ±1 millimeter is standard. High-end systems incorporate punch stations that create fastener holes, ridge vents, or interlocking features during the forming process.

The Stacking and Packing System is often underestimated by first-time buyers. Finished panels must be removed from the exit end, counted, stacked, and prepared for shipment. Manual stacking of long, flexible panels is physically demanding and risks damage. Automated stackers with magnetic or vacuum conveyors, edge alignment, and bundle strapping stations protect product integrity and reduce labor requirements.

Material Considerations

The choice of input material profoundly affects machine design and operational parameters.

Galvanized Steel remains the dominant substrate, offering an optimal balance of strength, formability, and corrosion resistance. Coating weights of Z100 to Z275 (100 to 275 grams per square meter) are typical. Material thickness ranges from 0.30 mm for light residential applications to 0.80 mm or more for industrial roofing.

Galvalume or Zinc-Aluminum Coated Steel provides enhanced corrosion resistance and is increasingly specified in coastal environments and for architectural applications. The coating’s different lubricity characteristics may require adjustments to roll clearances.

Prepainted Steel introduces additional complexity. The paint film, while decorative and protective, alters friction characteristics. Roll surfaces must be carefully finished to avoid marking the coating. Edge trimmers and scrap handling systems must accommodate paint chips and fines.

Aluminum is specified for premium applications requiring absolute corrosion resistance or reflective cooling properties. Aluminum’s lower strength and tendency to gall require slower forming speeds and specialized roll lubrication.

Copper, Zinc, and Stainless Steel occupy niche positions in architectural and heritage markets. These materials demand exceptional care in handling and forming, and are typically processed on dedicated lines.

Facility and Infrastructure Requirements

A roofing sheet manufacturing line imposes specific demands on the production facility.

Building Dimensions must accommodate the full length of the line, typically 30 to 50 meters from coil entry to panel stacker, plus clearance for coil storage and finished goods. Ceiling height must clear overhead cranes or coil handling equipment. Floor loading capacity must support concentrated machine weights and stored coil inventories.

Electrical Service requirements are substantial. Main drive motors for the roll former and decoiler, hydraulic power units, and servo systems may demand 50 to 150 kilowatts or more. Three-phase power is universal; voltage and frequency must match the machine builder’s specifications.

Compressed Air is required for mandrel expansion, shear operation, and accessory functions. A dedicated air compressor with adequate capacity and drying equipment prevents moisture-related control issues.

Overhead Cranes or Forklift Access for coil loading and finished goods removal are essential. Coil weights routinely exceed two tons; manual handling is neither safe nor practical.

Economic Analysis and Return on Investment

The decision to purchase a roofing sheet machine is fundamentally financial. A comprehensive investment analysis must consider both quantifiable returns and strategic positioning.

Revenue Potential is a function of machine capacity, market demand, and selling price. A mid-range line producing 30 meters per minute, operating one shift, can generate 4,000 to 6,000 tons of finished roofing annually. At prevailing market prices, this output translates to millions of dollars in revenue—though competition and market saturation must be realistically assessed.

Cost Structure includes raw material (typically 70% to 80% of selling price), direct labor, electrical consumption, tooling maintenance, facility overhead, and selling expenses. Successful manufacturers achieve gross margins of 20% to 30%, with net margins varying widely based on scale and efficiency.

Payback Periods for well-selected equipment in receptive markets range from 18 to 36 months. Manufacturers serving export markets or differentiated product niches achieve faster returns. Conversely, entry into saturated markets with commodity profiles may extend payback to five years or more.

Global Market Dynamics

The roofing sheet machine market mirrors broader trends in construction and industrial development.

Emerging Economies account for the majority of unit sales. Rapid urbanization, infrastructure investment, and the transition from traditional to modern building methods create sustained demand for metal roofing. Local manufacturers in Southeast Asia, Africa, and Latin America are aggressively investing in production capacity.

Mature Markets in North America, Europe, and Australasia exhibit replacement demand and specialization. Manufacturers upgrade existing lines for higher speed, tighter tolerances, and quick-change capability. Architectural standing seam and concealed fastener panels command premium pricing and require sophisticated machinery.

Export Opportunities for machine builders are substantial. Turkish, Chinese, and Indian manufacturers have gained significant market share with competitively priced equipment. European and North American builders retain leadership in high-speed, high-precision, and highly automated lines.

Selecting a Machine Supplier

The relationship between buyer and machine builder extends well beyond the purchase transaction. Due diligence should include:

Reference Visits to operating installations, ideally in applications similar to the buyer’s intended use. Photographs and videos are insufficient; witnessing production firsthand reveals machine condition, operator skill levels, and actual productivity.

Spare Parts and Service capabilities in the buyer’s region. Response times for technical support, availability of consumable tooling, and proximity of service technicians are critical factors.

Training Commitments specified in the sales agreement. Comprehensive training at the builder’s facility and on-site after installation reduces startup struggles and accelerates achievement of production targets.

Contractual Terms including performance guarantees, warranty periods, payment schedules, and remedies for non-performance. International buyers should carefully address shipping, customs clearance, and currency risk.

The roofing sheet manufacturing machine stands at the intersection of traditional shelter needs and advanced industrial technology. It is at once a mature product with decades of refinement and a dynamic platform for ongoing innovation. For those who master its operation and understand its markets, it offers the means to participate in one of humanity’s most fundamental activities: the creation of durable, affordable shelter.

Whether serving a local village with basic corrugated panels or supplying a global construction conglomerate with precision architectural roofing, the machine and its operator form the critical link between raw material and finished building. In an industry often romanticized for its craftsmanship, the roofing sheet machine demonstrates that manufacturing excellence is itself a form of craft—one measured not in hand tools but in micrometers, kilowatts, and panels per minute.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)