Selling Box Profile Machines: A Comprehensive Guide to Marketing High-Value Roll Forming Equipment

The box profile roofing sheet is among the most widely specified metal cladding products in the world. Its clean, symmetrical ribs, excellent structural performance, and straightforward installation have made it the default choice for industrial buildings, agricultural sheds, commercial developments, and residential projects across every continent. Behind this ubiquitous building product is the box profile machine—a roll forming system that represents a significant capital investment for manufacturers and a substantial revenue opportunity for equipment suppliers.

This article provides a comprehensive examination of the box profile machine market, the factors that drive purchasing decisions, and the strategies that equipment suppliers employ to win business in this competitive sector.

Understanding the Box Profile Product Category

Before attempting to sell box profile machines, one must thoroughly understand the product they produce and the market it serves.

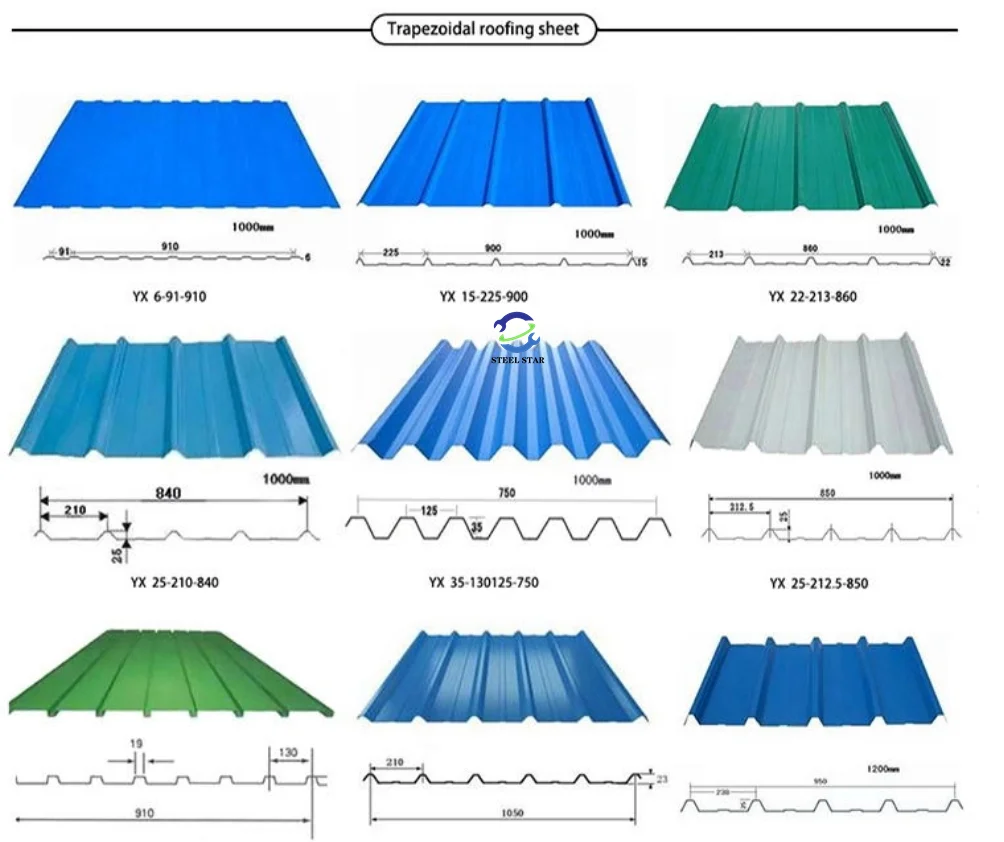

Profile Geometry distinguishes box profile from other roofing sheets. Unlike corrugated sheets with continuous sinusoidal curves, box profiles feature distinct, flat-topped ribs with vertical or near-vertical sidewalls. The ribs are typically spaced at 150 mm to 200 mm centers, with depths ranging from 25 mm for light-duty applications to 40 mm or more for heavy structural requirements. The “box” designation derives from the rectangular cross-section of the ribs, which provides excellent load-bearing capacity and a clean, contemporary appearance.

Material Specifications vary by application. Standard box profile sheets are formed from galvanized steel of 0.35 mm to 0.60 mm thickness for general cladding applications. Industrial and heavy commercial projects may specify 0.70 mm to 1.00 mm material. Galvalume-coated steel is increasingly specified for enhanced corrosion resistance, particularly in coastal and industrial environments. Prepainted steel in an extensive range of colors accounts for a growing share of the market, driven by architectural preferences and the longevity of modern coating systems.

End-Use Segments exhibit distinct requirements. Agricultural buyers prioritize low cost and functional durability. Industrial clients emphasize structural performance and long-span capability. Commercial developers demand consistent appearance and color accuracy. Residential contractors require precise cut lengths and reliable availability. A successful box profile machine seller understands these segment-specific needs and positions their equipment accordingly.

The Box Profile Machine Defined

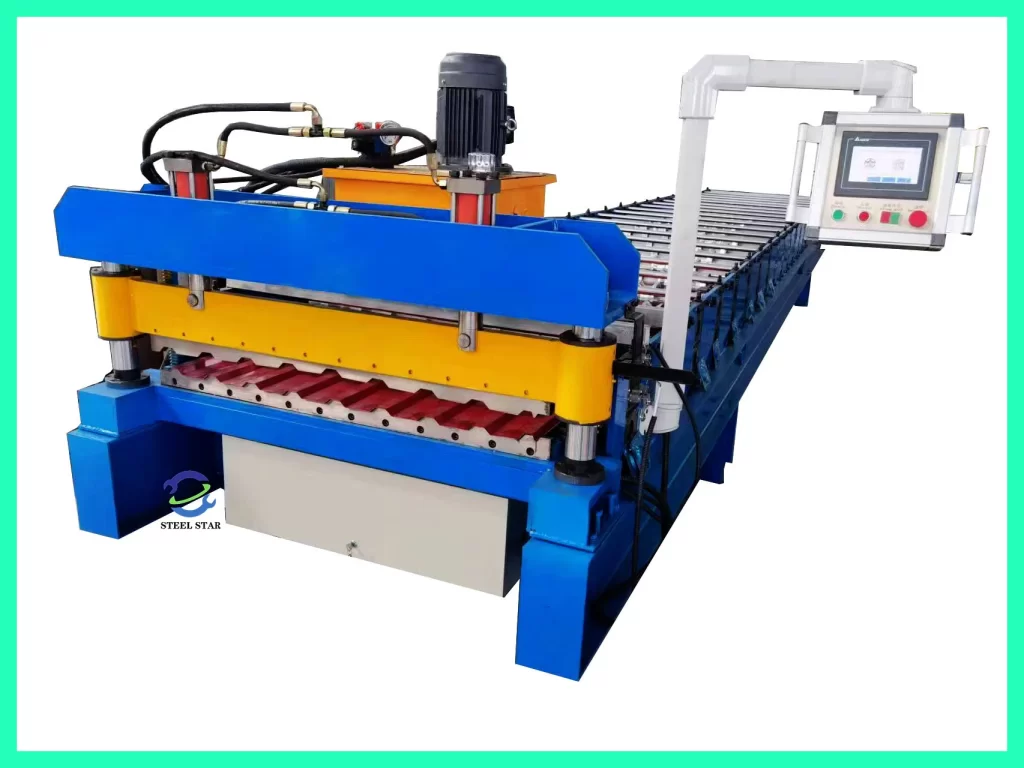

A box profile roll forming line transforms flat steel coil into finished roofing panels through a continuous process of progressive forming. The essential configuration includes:

Decoiling Equipment sized to the coil weights and widths the manufacturer intends to process. Single-end decoilers serve entry-level and mid-volume operations; double-end configurations eliminate downtime for coil changes in high-volume production.

Roll Forming Mill with 12 to 20 forming stations, each incrementally shaping the flat strip until the full box profile geometry is achieved. Mill construction must be sufficiently rigid to maintain precise alignment under the substantial forces generated when forming deep ribs in heavy-gauge material.

Cutting System typically a servo-electric flying shear that cuts panels to length without stopping material flow. Cut length accuracy of ±1 millimeter is standard. Hydraulic shears remain available on entry-level machines but have been largely superseded by servo technology in professional-grade equipment.

Control System integrating all line functions, storing profile recipes, and providing operator interface.

Stacking Equipment that receives cut panels, accumulates them into counted bundles, and presents the bundles for removal. Automation level ranges from manual offloading to fully automatic stacking with protective interleaving.

Optional Features include pre-punching units for fastener holes, side lap crimpers, edge trimmers, and protective film applicators for prepainted material.

The Buyer’s Perspective: Understanding Purchase Motivations

Effective selling begins with empathy—understanding the buyer’s situation, constraints, and objectives. Box profile machine purchasers fall into several distinct categories, each with characteristic motivations.

First-Time Manufacturers are typically entrepreneurs or small construction companies seeking to integrate backward into material supply. They have identified local demand for box profile sheets and wish to capture margin currently earned by distributors. Their primary concerns are capital preservation, rapid return on investment, and technical support during the learning curve. They may lack experience with roll forming, coil handling, or sheet metal processing. They require education as much as equipment.

Established Manufacturers Expanding Capacity operate existing roll forming lines and have proven market demand exceeding current production capability. They understand the technology, the costs, and the market. Their focus is on incremental capacity, improved efficiency, or enhanced capability—faster line speeds, quick-change tooling, or the ability to process heavier gauges. They evaluate proposals against hard financial metrics: cost per panel, labor reduction, and payback period.

Product Line Expanders currently manufacture other roofing profiles—corrugated, trapezoidal, or standing seam—and seek to add box profile capability. They have established sales channels and customer relationships. Their primary question is not whether they can sell box profile sheets, but how quickly they can integrate the new product line and achieve acceptable quality levels. They value rapid changeover, commonality of training and maintenance, and supplier experience with multi-profile operations.

Geographic Entrants are established manufacturers entering new regional markets. They may be domestic companies expanding to other states or international companies establishing local production. Their priorities include local service capability, compliance with regional standards, and supply chain integration.

The Technical Sales Approach

Selling box profile machines requires technical credibility. Buyers are making decisions that will affect their production capability, product quality, and competitive position for ten, twenty, or thirty years. They will not entrust these decisions to salespeople who cannot discuss forming forces, roll metallurgy, control architecture, and maintenance requirements with genuine authority.

Roll Tooling Design is a frequent subject of technical discussion. Buyers should understand that roll quality is the single most important determinant of panel quality and machine longevity. Rolls should be manufactured from certified tool steel, precision machined on CNC equipment, and subjected to rigorous inspection. The supplier should articulate their design philosophy—the number of forming stations, the distribution of deformation, the accommodation of springback, and the protection of coated surfaces.

Mill Construction merits detailed examination. Frame thickness, shaft diameter, bearing specifications, and drive train components distinguish robust machines from those that will develop misalignment and vibration under sustained production. Suppliers should be prepared to discuss material selections, safety factors, and design margins.

Control System Architecture has become a key differentiator. Buyers increasingly expect open-architecture systems using standard industrial components rather than proprietary, supplier-locked platforms. Remote diagnostics, production reporting, and integration capability with business systems are frequently specified requirements.

Service and Support Infrastructure is often the decisive factor when multiple suppliers offer technically comparable machines. Buyers seek assurance that spare parts will be available, that technical support will be responsive, and that field service technicians can arrive within acceptable timeframes. Suppliers should clearly articulate their parts inventory policies, service response commitments, and technical training programs.

Selling box profile machines is demanding work that requires technical competence, market insight, strategic patience, and genuine commitment to customer success. The rewards are correspondingly substantial: significant transaction values, enduring customer relationships, and the satisfaction of enabling customers to build their own successful businesses.

The best machine sellers are not merely vendors of capital equipment. They are consultants who help customers select appropriate technology, educators who train operators and supervisors, and partners who remain engaged throughout the equipment’s long service life. They understand that a box profile machine is not a commodity to be priced and shipped, but a solution to be configured, installed, and supported.

In an increasingly competitive global market, these fundamental principles remain unchanged. Buyers seek confidence before commitment. They want assurance that the machine will perform as promised, that the supplier will respond when needed, and that their investment will generate returns for years to come. Suppliers who provide this confidence, through technical excellence and genuine customer focus, will continue to earn business regardless of economic conditions or competitive pressures.

The box profile machine market will evolve. New entrants will emerge, technologies will advance, and customer expectations will rise. But the essential nature of the transaction—a substantial, long-term commitment based on trust in the supplier’s capability and integrity—will endure. For those who master the art and science of selling these sophisticated systems, the market offers enduring opportunity.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)