The Sheet Metal Decoiler: The Essential Gateway to Automated Metal Forming

In the high-speed, precision-driven world of sheet metal fabrication, every efficient production line begins with a single, critical step: properly feeding the raw material. The Sheet Metal Decoiler, also known as an uncoiler or payoff reel, is the unsung hero that performs this fundamental task. It is the starting point, the gateway that transforms a static, heavy coil of metal into a smoothly flowing, controlled stream of material ready for punching, slitting, roll forming, or stamping.

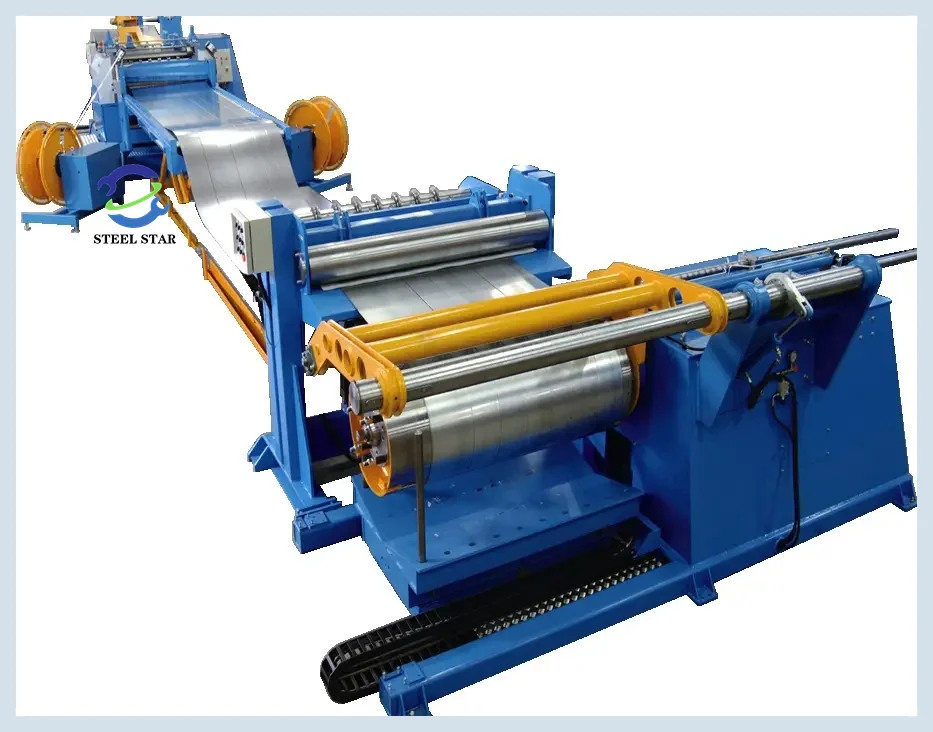

What is a Sheet Metal Decoiler?

A sheet metal decoiler is a powered or passive mechanical device designed to securely hold, support, and unwind a coil of sheet metal (typically steel, aluminum, stainless steel, or copper) and feed it into a downstream processing machine. Its primary function is to provide a stable, controlled pay-off of material while maintaining proper tension and alignment—a prerequisite for any high-quality forming or cutting process.

Core Components and Functionality

While designs vary based on capacity and automation level, a standard decoiler comprises several key components:

- Mandrel (Shaft or Arbor): The expandable central shaft that is inserted through the coil’s inner diameter (ID). It expands mechanically (using segments or wedges) or pneumatically to grip the coil from the inside, ensuring no slippage during unwinding.

- Coil Car or Saddle (Optional but Common): A hydraulically or electrically powered carriage that moves the heavy coil from a loading position onto the decoiler mandrel, eliminating the need for crane operation and enhancing safety.

- Side Guides or Cone Disks: Adjustable plates or cones placed on the mandrel on either side of the coil to control lateral movement and ensure the coil unwinds axially straight, crucial for maintaining material feed alignment.

- Braking System: The heart of tension control. This can be a mechanical friction brake, a pneumatic brake, or, in more advanced models, an electric servo-driven brake. It provides controlled resistance to prevent the coil from unraveling uncontrollably due to its own inertia.

- Support Frame & Base: A robust welded steel structure that provides stability and often includes height adjustment to align the material feed line with the downstream equipment.

- Peel-off Plate or Straightening Guide: A curved or flat plate at the exit point that helps initiate the unwinding (“peeling”) of the first few turns of the coil and guides the material towards the next station.

Types of Decoilers

The choice of decoiler depends on coil weight, material thickness, line speed, and required precision:

- Passive Decoiler (Non-Powered): Relies on the pulling force of the downstream machine (like a press feeder or roll former) to unwind the coil. Braking resistance is manually or pneumatically set. Ideal for lighter coils and simpler applications.

- Powered Decoiler: Incorporates a drive motor (often AC or servo) that actively assists in unwinding the coil. This reduces pull force on the material, minimizes stretching or scratching of sensitive surfaces, and is essential for high-speed lines or processing fragile pre-painted metals.

- Double-Arm / Cantilevered Decoiler: Features a mandrel supported only on one side, allowing for extremely fast and easy loading of coils with a crane or forklift. Common for medium-duty applications.

- Through-Shaft Decoiler: The mandrel is supported by bearings on both ends, providing maximum stability and weight capacity for very heavy, wide coils used in heavy-gauge slitting or processing lines.

- Recoil/Combination Decoiler: A versatile unit that can both unwind and rewind material, used in specific processes like coating or corrective levelling.

Why the Decoiler is Critical to Production Success

A properly selected and maintained decoiler is not just a convenience; it is a vital contributor to overall line performance:

- Ensures Feed Stability & Precision: Consistent, controlled unwinding is the foundation for accurate punching, precise roll forming, and clean slitting. Any inconsistency here amplifies downstream.

- Protects Material Quality: Proper tension control and alignment prevent material scratching, edge damage, and plastic deformation (stretching) of the sheet.

- Enhances Safety: Securely holding multi-ton coils and providing controlled unwinding prevents catastrophic unspooling, protecting both personnel and equipment.

- Maximizes Uptime & Efficiency: Features like motorized coil cars and quick-expand mandrels drastically reduce coil changeover time, increasing overall equipment effectiveness (OEE).

- Enables Automation: As the first link in an automated line, a modern decoiler integrated with PLC controls allows for seamless, synchronized operation with feeders, straighteners, and primary machines.

Key Selection Criteria

When specifying a decoiler, engineers must consider:

- Coil Capacity: Maximum coil weight (tons), outer diameter (OD), inner diameter (ID), and material width.

- Material Specifications: Type, thickness range, and surface sensitivity (e.g., pre-painted, polished).

- Line Speed: Maximum required unwinding speed (meters per minute).

- Tension Control Method: Required precision of braking (mechanical, pneumatic, or servo-driven).

- Integration Level: Compatibility with coil cars, threading systems, and central line PLC.

The sheet metal decoiler is a masterpiece of focused engineering—a machine designed to perform one task perfectly. From simple cantilevered reels to fully automated, servo-controlled power decoilers integrated into smart factories, this equipment ensures that the vital first step in the metal forming process is executed with reliability, precision, and safety. It quietly sets the stage for all that follows, making it an indispensable and foundational component in the modern manufacturing landscape. Without it, the seamless automation of metal fabrication would simply not be possible.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)