Sheet Metal Decoilers: The Essential Guide to Buying the Right Machine for Your Operation

In the world of metal fabrication, efficiency begins at the very start of the production line. Before any roll forming, stamping, cutting, or punching can occur, the coil of sheet metal must be unwound and fed into the processing equipment. This critical first step is performed by a sheet metal decoiler—a machine that often receives less attention than the forming tools it serves, yet is fundamental to productivity, material quality, and operator safety.

For fabricators considering an equipment purchase, the decision to invest in a decoiler is not simply a matter of acquiring a coil holder. It is a strategic choice that affects setup times, material utilization, and the overall flow of production. This article provides a comprehensive overview of sheet metal decoilers available on the market, the factors that distinguish one machine from another, and the considerations that should guide a purchasing decision.

Understanding the Role of a Decoiler

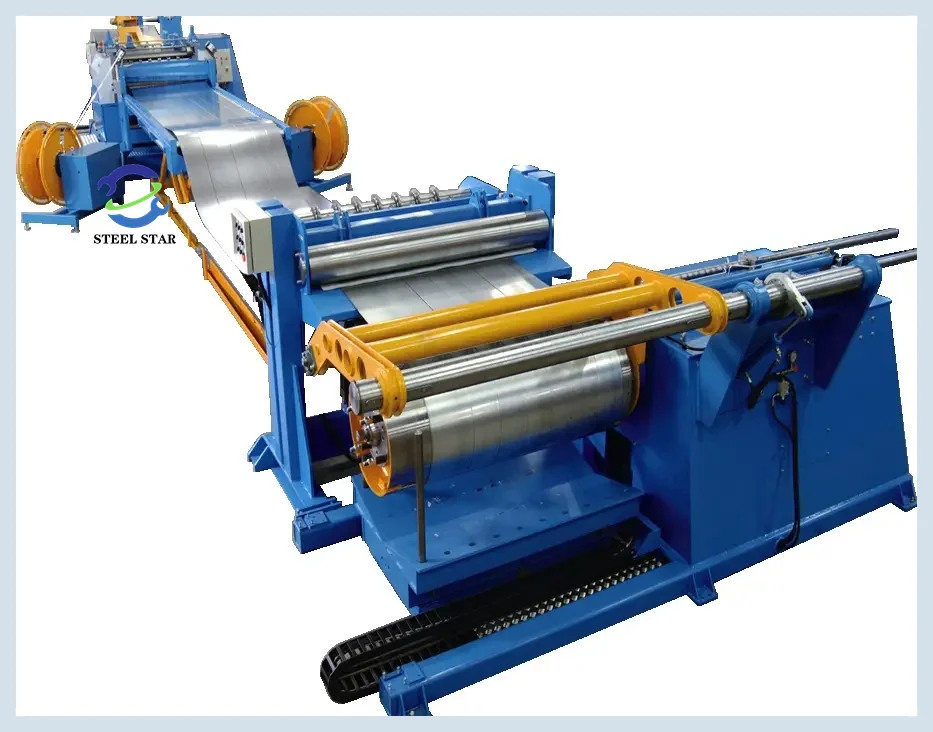

A sheet metal decoiler, also known as an uncoiler or payoff reel, supports a coil of metal and allows it to rotate freely so that material can be unwound under controlled tension. In its simplest form, a decoiler is a passive mandrel that relies on the downstream equipment to pull material. In more sophisticated configurations, the decoiler is motorized, synchronized with the feed line, and equipped with brakes or regenerative drives to maintain consistent loop control.

The importance of a quality decoiler cannot be overstated. A coil that is not properly centered will introduce tracking errors. Inconsistent tension will cause material to flutter or buckle. Damaged edges from poorly maintained mandrels can propagate cracks during forming. The decoiler is the foundation upon which the entire fabrication process rests.

Types of Sheet Metal Decoilers

The market offers several distinct categories of decoilers, each suited to specific production environments and material characteristics.

Manual or Mechanical Decoilers represent the entry level. These machines typically feature a simple spindle with expanding arms operated by a hand crank or wrench. Coil rotation is passive, with material pulled by the feed mechanism of the downstream press or roll former. Manual decoilers are inexpensive, require no electrical connection, and are adequate for light-gauge materials and intermittent production. However, they lack tension control and can be difficult to load without overhead lifting equipment.

Motorized Single-End Decoilers incorporate an electric motor and gearbox to drive the mandrel. The motor is controlled by a loop sensor—typically a photoelectric eye or mechanical arm—that maintains a free-hanging loop of material between the decoiler and the feed line. This configuration provides consistent, drag-free unwinding and is the standard for most continuous roll forming and stamping operations. Single-end machines occupy minimal floor space but require coil changes to be completed before the next coil can be loaded.

Double-End Decoilers, also called dual-mandrel or swing-arm decoilers, feature two spindles mounted on a rotating base. While one coil is feeding material, the operator can load a fresh coil onto the opposite mandrel. When the active coil runs out, the machine swings 180 degrees and the new coil is indexed into position. This arrangement virtually eliminates downtime for coil changes, making it indispensable for high-volume production environments.

Heavy-Duty Cone-Type Decoilers are designed for narrow coils or applications where the coil inner diameter varies significantly. Instead of expanding segments, these machines use opposing cones that grip the coil from both ends. Cone-type decoilers are common in tube and pipe mills and in operations processing slit mults—multiple narrow coils slit from a master coil.

Floor-Mounted Versus Reel-Type distinctions also matter. Floor-mounted decoilers support the coil directly on the shop floor, requiring a pit or ramp for loading. Reel-type machines elevate the coil, allowing forklift or crane loading from the side. The choice is largely dictated by material handling equipment and floor layout.

Key Specifications and Features

When evaluating decoilers for sale, buyers must match machine specifications to their production requirements. Several parameters are non-negotiable.

Coil Capacity is the most fundamental specification, expressed as the maximum coil weight the machine can support. Light-duty decoilers may handle 1,000 to 3,000 pounds, while heavy industrial units can exceed 20,000 pounds. Equally important is the coil width capacity, which determines the maximum material width the machine can accommodate.

Mandrel Expansion Range must match the coil inner diameter. Most coils are supplied with 16-inch, 20-inch, or 24-inch IDs, but metric sizes and specialty dimensions exist. A decoiler mandrel should expand sufficiently to grip the coil securely without collapsing the core, and contract enough for easy removal of the empty core.

Motor Horsepower and Drive Type determine the machine’s ability to handle heavy coils and maintain speed. AC flux-vector drives are now standard, providing precise speed control and regenerative braking. Some machines offer constant tension features, which are essential for sensitive materials or applications requiring tight thickness tolerances.

Snubber Rolls and Peeler Units are valuable accessories that deserve attention. A snubber roll prevents the outer wrap of the coil from springing open during loading. A peeler unit initiates the lead end of the coil and feeds it into the straightener or press. These features reduce setup time and protect operators from sharp, tensioned coil ends.

Threading and Support Systems vary widely. Basic decoilers require the operator to manually pull material from the coil. Higher-end machines include powered threading tables, coil cars for loading, and hold-down arms that prevent telescoping coils from shifting during unwinding.

Installation and Infrastructure

The material handling pathway must also be considered. How will coils be transported from storage to the decoiler? Will a coil ram or floor-mounted coil car be required? Is there adequate clearance for a forklift to position coils onto the mandrel? These logistics are as important as the machine specifications themselves.

Making the Purchase

The decision to purchase a sheet metal decoiler should begin not with the machine itself, but with an analysis of the production process. What are the bottlenecks? Is excessive time spent on coil changes? Does material damage occur during unwinding? Is the existing decoiler limiting the speed of downstream equipment?

Once the operational requirements are defined, the selection process becomes one of matching those requirements to available machines. Reputable suppliers will request detailed information about material specifications, coil dimensions, production volumes, and facility constraints before making recommendations. They should also provide references to customers with similar applications.

A sheet metal decoiler is not the most glamorous machine in a fabrication shop. It does not form intricate profiles or punch complex patterns. But it is the machine that makes all subsequent operations possible. A decoiler that is correctly specified, properly installed, and conscientiously maintained will quietly perform its duty for decades, delivering coil after coil with minimal attention.

For the fabricator considering a purchase, the message is clear: invest in quality, match the machine to the application, and recognize that the decoiler is not merely an accessory but a cornerstone of efficient metal processing. Whether new or used, manual or fully automated, the right decoiler is an investment that pays returns in every foot of material processed.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)