Slab Floor Decking Panel Machine: Revolutionizing Modern Construction Efficiency

The demand for rapid, cost-effective, and structurally sound construction has propelled the adoption of composite floor systems in modern high-rises, commercial buildings, and industrial facilities. At the core of these systems is the Slab Floor Decking Panel, also known as composite metal decking or corrugated steel decking. The specialized equipment that manufactures this vital component with precision and speed is the Slab Floor Decking Panel Machine. This highly engineered production line is critical to meeting the scale and quality requirements of contemporary construction projects.

What is a Slab Floor Decking Panel Machine?

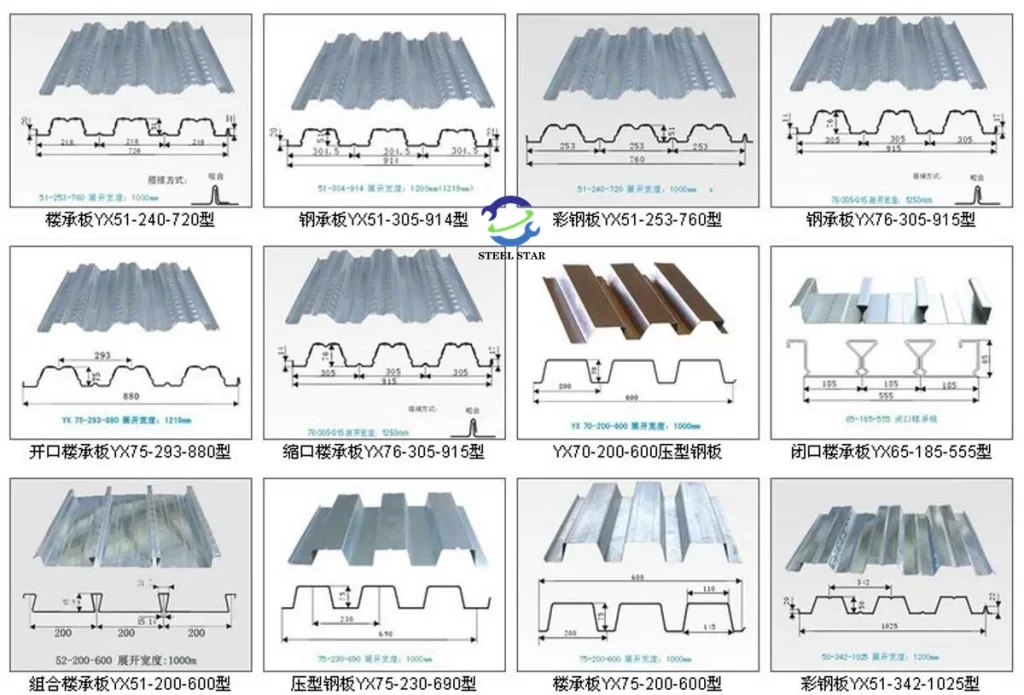

A slab floor decking panel machine is a heavy-duty roll forming production line designed to transform wide, high-tensile steel coils into the long, profiled steel sheets used as permanent formwork in composite concrete floors. These panels are characterized by their trapezoidal or re-entrant rib patterns, which provide structural strength, create a mechanical bond with poured concrete, and often feature embossments for enhanced composite action.

The machine operates on the continuous cold roll forming principle, progressively shaping the flat steel strip through a series of roller dies. The final product serves a dual purpose: it acts as a working platform during construction and as tensile reinforcement within the finished concrete slab.

Core Components and Production Process

A complete and automated decking panel line consists of several integrated stations, each serving a specific function:

- Heavy-Duty Decoiler & Feed-In System: A robust mandrel-type decoiler handles large, heavy coils (often 10-20 tons) of galvanized or galvannealed steel. An entry guide and levelling system ensure flat, aligned material entry.

- Embossing/Punching Unit (Critical Feature): This is a key differentiator. Before forming, servo-controlled presses emboss the steel strip with precise patterns (dots, lines, or lugs). These embossments are engineered to prevent separation and ensure perfect shear connection between the steel deck and the hardened concrete. Some lines may also incorporate inline side-trim and edge-punching for lap joints.

- High-Strength Roll Forming Mill: The heart of the machine, featuring a series of 15-25+ sets of hardened steel roller dies. Each station incrementally bends the steel into the final decking profile—common profiles include deep trapezoidal ribs (for longer spans) and narrow re-entrant ribs.

- Flying Cut-Off System: A high-precision, hydraulic or servo-driven cutting mechanism shears the continuously formed panel to exact, pre-programmed lengths. Advanced systems use an “on-the-fly” rotary shear or flying saw for a clean, burr-free cut without stopping the line.

- Output Conveyor & Stacking System: An automatic run-out table conveys the finished panels. A programmed stacking system counts, aligns, and bundles the panels for strapping and shipment, minimizing manual handling of the long, often heavy sheets.

- Centralized Control System: A PLC (Programmable Logic Controller) with an intuitive HMI (Human-Machine Interface) controls the entire line—from feed speed and embossing pattern to cut length and production count. This ensures consistent quality and easy changeover between different panel profiles and lengths.

Technical Advantages and Impact on Construction

- Engineered Structural Performance: The machine produces panels with consistent, code-compliant geometry and embossment patterns, guaranteeing predictable load-bearing capacity, span capabilities, and composite behavior in the final floor system.

- Unmatched Production Speed and Volume: Capable of producing panels at speeds of 30-80 meters per minute, a single line can supply enough decking for multiple large-scale projects, enabling just-in-time delivery to construction sites and significantly accelerating project timelines.

- Material Efficiency and Reduced Waste: Precise computer-controlled cutting optimizes yield from each coil. The integrated production of a finished structural product from raw coil minimizes on-site fabrication waste.

- Enhanced Site Safety and Labor Efficiency: Pre-manufactured panels delivered to site are immediately ready for installation as a safe working platform, reducing fall hazards and the labor-intensive process of building traditional timber formwork.

- Design Flexibility: Advanced machines can be equipped with quick-change roll systems, allowing a single production line to manufacture various profiles, depths, and widths to meet specific architectural and engineering requirements.

Economic and Industry Significance

Investing in a slab floor decking panel machine represents a major capital decision for steel profile manufacturers, with high-performance lines ranging from $500,000 to over $2 million. This investment is driven by the growing global demand for steel-framed construction. The machine enables manufacturers to become key suppliers to the construction industry, providing a critical component that enhances the speed, safety, and economy of building erection.

The slab floor decking panel machine is far more than a sheet metal former; it is a precision engineering system that fabricates a critical structural building element. By automating the production of composite decking with unwavering accuracy, it underpins the economic and structural logic of modern steel-framed construction. For the industry, it translates into faster project completion, reduced overall costs, and built-in structural integrity. As urbanization and the need for efficient construction methodologies continue to grow, this machine stands as a foundational technology, quite literally forming the floors upon which modern cities are built.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)