A Standing Seam Roll Forming Machine (often just called a Standing Seam Machine) is a specialized piece of equipment used in the roofing industry to create standing seam metal panels, commonly used for high-performance metal roofing systems. Here’s an overview of each of the machine’s functions and its uses:

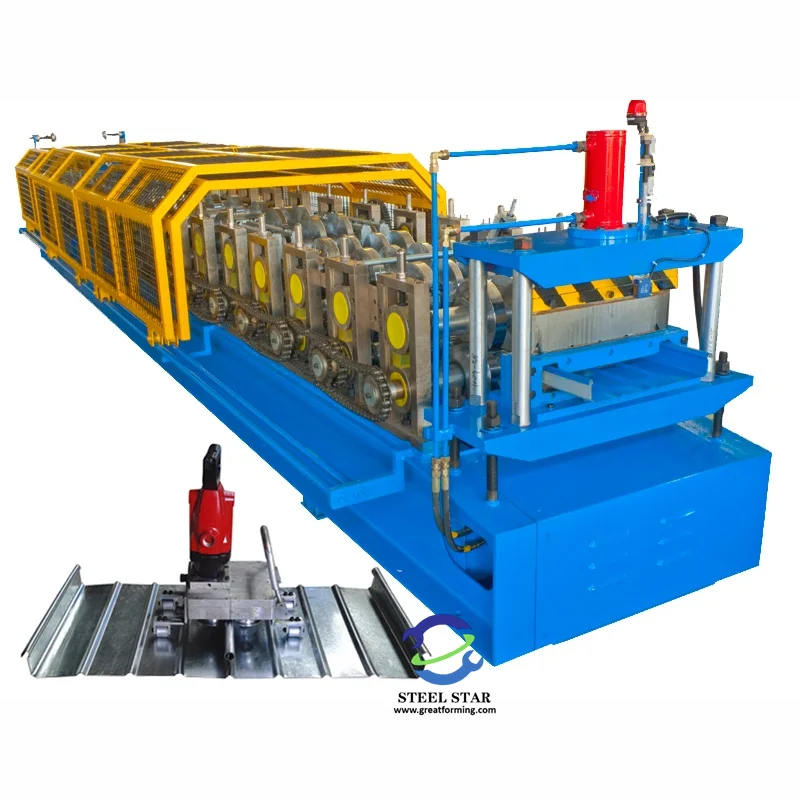

- Standing Seam Roll Forming Machine: This machine transforms metal coils into standing seam roofing panels. It operates by feeding metal through a series of rollers, gradually forming the desired profile. The machine allows for consistent, high-quality panel production suitable for large-scale roofing projects.

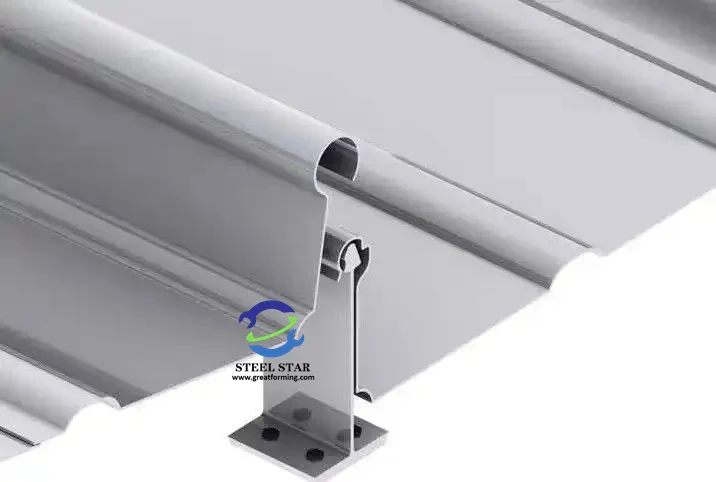

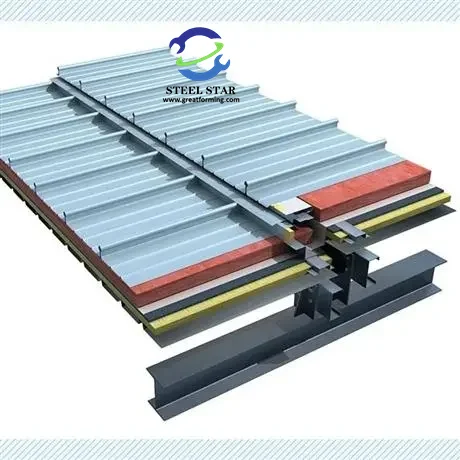

- Standing Seam Forming Machine: Sometimes used interchangeably with roll forming machines, this term specifically refers to machines designed to create the “standing seam” profile. Standing seam roofing panels feature a raised interlocking seam, which is essential for weather resistance and durability.

- Portable Standing Seam Machine: Some machines are portable, allowing contractors to take them directly to job sites, which is beneficial for projects requiring custom lengths or on-site adjustments.

- Key Features:

- Adjustable Width and Height: These machines often allow for adjustments to create various panel sizes.

- High Production Speed: Efficiently creates panels, supporting quick installation on-site.

- Automation Options: Modern models often include automation, allowing for precise cuts and forming with minimal manual intervention.

- Applications: Standing seam panels produced by these machines are widely used in residential, commercial, and industrial roofing due to their durability, resistance to harsh weather, and attractive appearance.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)