Steel Coil Processing Machinery: The Backbone of Modern Manufacturing

Introduction: The Unseen Engine of Industry

From the skeletal frames of skyscrapers and the bodies of automobiles to the humble household appliance, the journey of modern steel often begins in the same form: the massive, tightly wound steel coil. Transforming these heavy coils into usable products is the critical, yet often overlooked, domain of steel coil processing machinery. This sophisticated equipment is the essential bridge between raw steel production and virtually every metal-fabricating industry, enabling efficiency, precision, and scalability.

What is Steel Coil Processing Machinery?

Steel coil processing machinery refers to a broad category of industrial equipment designed to handle, straighten, cut, and form coiled steel sheet or strip metal. These machines automate and streamline the conversion of coils into flat sheets, blanks, or directly formed components, replacing slow, labor-intensive, and inconsistent manual methods.

The core of any coil processing line typically involves three key stages:

- De-Coiling & Feeding: Unwinding the heavy coil under controlled tension.

- Straightening: Removing the inherent coil curvature (“coil set”) through a series of leveling rolls to produce perfectly flat material.

- Processing: The primary operation, such as cutting or forming.

Major Types of Steel Coil Processing Machines

- Cut-to-Length Lines (CTL Lines):

- Function: The most common type, designed to precisely slit a wide master coil into narrower strips (slitting lines) or shear it into flat sheets of specific lengths (cut-to-length lines).

- Key Components: Uncoiler, peeler/feeder, leveler, shear (flying or stationary), stacker.

- Applications: Production of blank sheets for presses, panels for construction, and parts for appliance manufacturing.

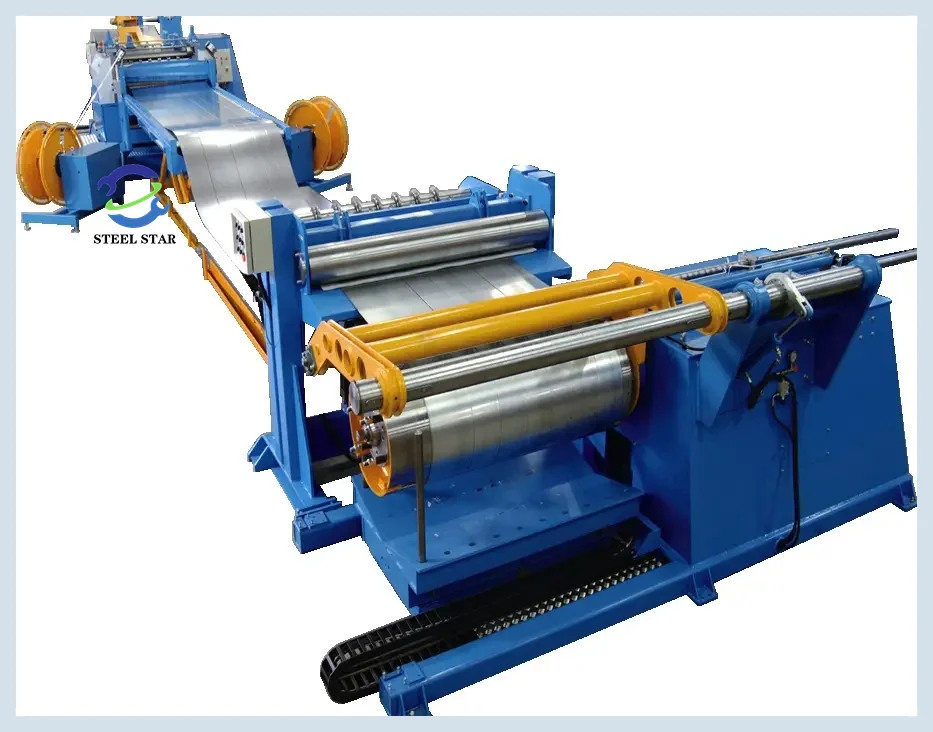

- Slitting Lines:

- Function: A specialized subset of CTL lines focused solely on longitudinal cutting. A wide coil is fed through a set of circular slitter knives to produce multiple narrower coils.

- Key Components: Uncoiler, slitter head with tooling, separator, tension stand, re-coiler.

- Applications: Creating strips for tube mills, edge trim, or specific width requirements for further processing.

- Roll Forming Machines:

- Function: These machines progressively shape flat coil stock into continuous cross-sectional profiles (like purlins, roof panels, guardrails, and door frames) through a series of paired roller dies.

- Key Components: Uncoiler, pre-punching/notching unit, roll forming station with sequential stands, cut-off press, run-out table.

- Applications: High-volume production of long, consistent metal profiles for construction, automotive, and storage systems.

- Blanking Lines/Press Feed Lines:

- Function: Highly automated lines that feed coil stock directly into stamping or punching presses. They often include precision servo-feed mechanisms to advance material at high speeds for each press stroke.

- Key Components: Uncoiler, heavy-duty leveler, servo-feed, scrap chopper.

- Applications: Automotive body parts, electronic chassis, and any high-volume stamped metal component.

Key Technological Advancements

Modern steel coil machines are marvels of integration and control, driven by several key technologies:

- CNC & Servo-Driven Systems: Provide unparalleled precision in length measurement, feed control, and synchronization of cutting/forming actions, minimizing material waste.

- Advanced Leveling Technology: Multi-roll levelers with digital adjustment ensure perfectly flat material, which is crucial for high-quality forming and welding.

- Automated Handling Systems: Robots and automated stackers for finished sheets or profiles reduce labor, increase safety, and protect material surface finish.

- IoT & Predictive Maintenance: Sensors monitor machine health (vibration, temperature, load), enabling data-driven maintenance to prevent unplanned downtime.

- Quick-Change Tooling: Systems that allow for rapid changeover of slitter knives or roll forming dies, crucial for just-in-time manufacturing with small batch sizes.

The Critical Role in Industry

The importance of this machinery cannot be overstated:

- Efficiency: Processes raw steel at speeds impossible by hand, with continuous operation.

- Precision & Consistency: Delivers repeatable accuracy in dimensions and shape, essential for automated assembly and high-quality end products.

- Material Yield Optimization: Advanced controls and precision cutting drastically reduce scrap, saving significant material costs.

- Labor Safety: Automates the handling of heavy, sharp-edged coils, creating a safer work environment.

- Enabler of Mass Production: Makes the high-volume, cost-effective production of everything from cars to canned goods feasible.

Steel coil processing machinery is the indispensable, intelligent heart of secondary steel operations. It transforms a raw, bulky commodity into a refined, ready-to-use industrial material. As demands for lighter, stronger, and more complex steel products grow, the evolution of this machinery—towards greater automation, connectivity, and flexibility—will continue to drive innovation and efficiency across the global manufacturing landscape. For any industry that relies on formed sheet metal, investing in the right coil processing technology is not just an operational cost; it is a fundamental strategic decision for competitiveness.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)