Steel Coil Processing Machines: The Engine of Modern Metalworking

From the skeletons of skyscrapers to the bodies of automobiles and the casings of household appliances, flat-rolled steel in coil form is the foundational material of modern manufacturing. Transforming these massive, compact coils into usable components is the critical task of steel coil processing machines—a sophisticated family of equipment that forms the vital link between steel mills and finished products.

The Starting Point: The Steel Coil

A steel coil is a continuous, ribbon-like sheet of metal, typically ranging from 0.2mm to over 6mm in thickness and weighing several tons, wound tightly onto itself. To convert this raw material, a coordinated processing line is required, comprising several key machines that perform sequential operations with precision and high speed.

Core Machines in a Processing Line

A typical integrated line features the following essential machines, often controlled by a centralized automation system:

1. Decoiler / Uncoiler

- Function: This is the starting point. It securely holds the heavy coil and unwinds it under controlled tension, feeding the steel strip into the line. Modern decoilers are motor-driven with automatic edge alignment (CPC) to ensure straight entry.

- Types: Include single mandrel, double mandrel (for non-stop operation), and cantilever styles for heavier coils.

2. Leveller / Flattener

- Function: Steel coil can have inherent curvature or minor deformations (coil set). A leveller passes the strip through a series of alternating rolls (often 5 to 9 rollers) that apply precise bending stresses to eliminate these imperfections, ensuring perfectly flat material for further processing.

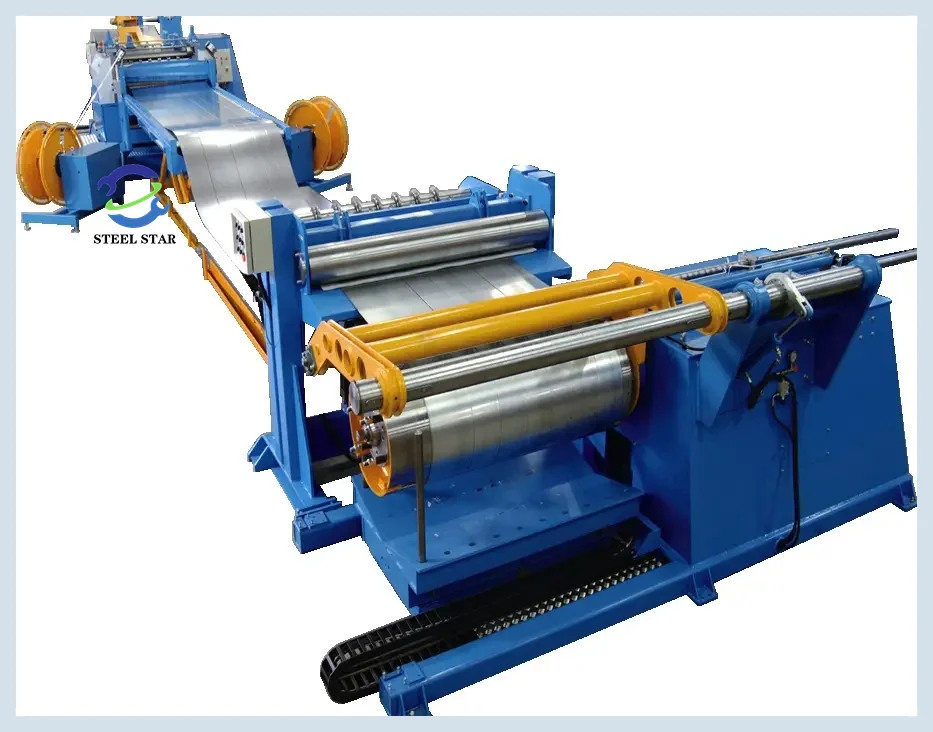

3. Shearing or Slitting Machine

This is a major branch point for two fundamental processing paths:

- Cut-to-Length (CTL) Line: Features a precision flying shear or guillotine shear. It cuts the continuously moving strip into pre-programmed, flat sheets or blanks. Essential for producing panels for appliances, building walls, or automotive parts.

- Slitting Line: Employs a set of hardened, razor-sharp circular slitter knives mounted on arbors. As the coil passes through, it is sliced longitudinally into multiple narrower strips, which are then rewound onto separate recoilers. This is the process for creating narrower coils for subsequent forming, like producing strips for purlin machines or tube mills.

4. Edge Trimmer (in Slitting Lines)

- Function: Removes the irregular, often work-hardened edges of the master coil to ensure clean, smooth edges on the slit strands and to protect downstream equipment.

5. Recoiler / Tension Stand

- Function: In a slitting line, this machine rewinds the slit strands into tight, manageable coils. In advanced lines, it provides critical back tension to ensure stable, consistent processing throughout the system.

6. Stacker / Unloader

- Function: At the end of a CTL line, this automated system neatly collects and stacks the finished sheets onto pallets or skids for forklift removal, often incorporating counting and sheet separation systems.

Advanced Technology and Automation

Modern coil processing lines are marvels of industrial automation:

- Programmable Logic Control (PLC) & HMI: The entire line—speed, tension, cut lengths, and knife positioning—is managed from a central console. Operators input parameters for different coil dimensions and orders.

- Precision Servo Drives: Provide exceptionally accurate control for shearing and positioning, minimizing material waste at the front and tail ends of the coil.

- In-Line Inspection: Laser sensors and vision systems continuously monitor strip profile, width, and surface for defects.

- Hydraulic Systems: Deliver the immense, controlled force needed for leveling, shearing, and maintaining tension.

Applications and Impact

The products from these machines feed countless downstream industries:

- CTL Sheets: For appliance exteriors, automotive frames, building panels, and shipbuilding.

- Slit Coils: For roll-forming lines (roofing, wall panels), tube and pipe mills, stamping presses, and the production of various edge profiles.

Steel coil processing machines are the unsung workhorses of heavy industry. They transform a raw, industrial commodity into a precise, ready-to-use engineering material with remarkable efficiency. By integrating mechanical power, precision tooling, and digital intelligence, these systems enable the mass production of consistent, high-quality components. Their relentless evolution towards greater speed, accuracy, and flexibility continues to drive innovation across the global manufacturing landscape, forming the essential first step in bringing countless metal products to life.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)