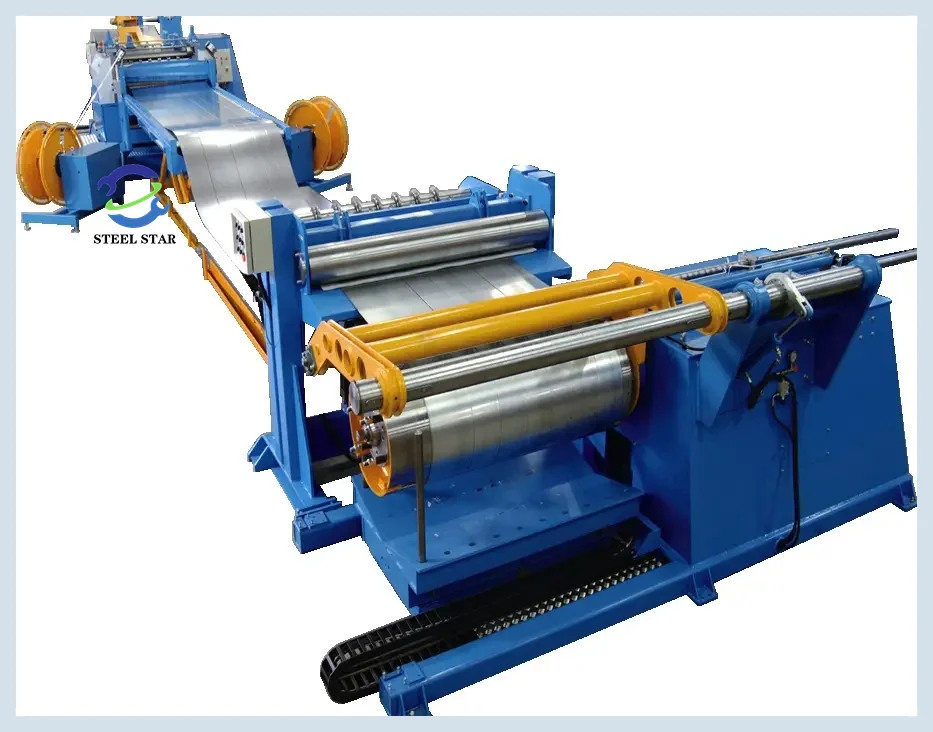

Steel Coil Slitting Machine: Precision in Strip Processing

In the world of metal fabrication and processing, efficiency and precision are paramount. The steel coil slitting machine stands as a critical piece of equipment, transforming wide master coils into multiple, narrower strips of specific widths with consistent accuracy. This process is essential for feeding downstream operations that produce a vast array of products, from automotive components and appliance casings to construction materials and electronic enclosures.

Core Function and Process

At its heart, a slitting machine is designed to longitudinally cut (or slit) a large coil of steel—often weighing several tons—into a number of narrower coils. The basic process involves four key stages:

- Uncoiling: The master coil is loaded onto an unwinding mandrel (decoiler). A peeler arm helps separate the leading edge, which is then fed into the machine.

- Flattening & Guidance: The steel strip passes through a leveler or flattening device to remove any coil set or crossbow, ensuring a flat, uniform material enters the cutting section. Edge guidance systems (EPCs) maintain lateral alignment.

- Slitting: This is the core operation. The strip passes through a set of upper and lower circular slitter knives, mounted on arbors. The arrangement and spacing of these hardened, tool-steel knives determine the number and width of the strips produced. There are three primary slitting methods:

- Wrap Slitting: The strip wraps around the top arbor, providing good stability for thicker materials.

- Pull-Through Slitting: The knives are set in a neutral position, and the strip is pulled through by the downstream tension. Ideal for medium-range thicknesses and high precision.

- Loop Slitting: The strip forms a loop between the slitter head and the tension stand, offering excellent control for thin, sensitive materials.

- Separation & Recoiling: The slit strands are separated by spacers and guided individually onto separate mandrels on the rewind mandrel. Precise tension control during rewinding is crucial to producing tight, even, and properly aligned narrow coils.

Key Components and Technological Features

Modern slitting lines are sophisticated systems integrating several components:

- Decoiler & Recoller: Heavy-duty mandrels with expansion mechanisms to hold coils securely. They are often equipped with hydraulic or electric drives for controlled tension.

- Slitter Head/Base: The rigid frame housing the knife arbors. Quick-change knife systems are now standard, drastically reducing setup time for different width orders.

- Scrap Winders: Automatically collect the edge trim (skeleton) from both sides of the master coil, ensuring a clean production line.

- Drive & Control System: Modern machines use PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) panels for centralized control. They manage speed, tension, alignment, and diagnostic functions.

- Ancillary Systems: These can include precision side trimmers, static eliminators, surface protection films, and automatic strip lubrication systems.

Advantages and Industry Impact

The use of coil slitting machines offers significant benefits:

- Material Efficiency: Minimizes waste compared to other cutting methods, optimizing material yield.

- High Productivity: Capable of processing thousands of meters of steel per hour, far outperforming blanking or shearing individual pieces.

- Superior Edge Quality: Produces clean, burr-minimized edges, which is vital for subsequent forming, stamping, or welding processes.

- Consistency and Precision: Ensures uniform strip width and tension across all strands, batch after batch.

- Flexibility: Quick tooling changes allow manufacturers to respond swiftly to custom orders for various widths.

Applications and Material Range

While primarily for steel, these machines also process aluminum, copper, and other metals. They handle a wide thickness range, from thin, delicate foils (0.1 mm) up to heavy-plate steel (over 6 mm). The resulting narrow coils are directly used in roll forming lines, tube mills, stamping presses, and as blanked parts.

The steel coil slitting machine is more than just a cutter; it is a precision-engineered system that forms the backbone of efficient metal strip preparation. Its continuous evolution—with advancements in automation, digital controls, and predictive maintenance—ensures it remains indispensable in meeting the demanding, high-volume, and high-precision needs of modern metal-intensive industries. By delivering material in the exact required form, it enables manufacturers to enhance productivity, reduce costs, and maintain stringent quality standards.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)