The Architectural Chassis: Unpacking the Power of Steel Frame Machines

In the realm of modern construction, the shift towards speed, precision, and sustainability has found a powerful ally in light gauge steel framing. This structural skeleton, rivaling traditional wood and concrete, forms the walls, floors, and roofs of everything from residential homes to mid-rise apartments and commercial complexes. The technology that makes this revolution possible—and profitable—is the Steel Frame Machine. More than a simple tool, it is a sophisticated, computer-driven factory that transforms raw steel coil into perfectly engineered structural components.

Core Concept and Evolution

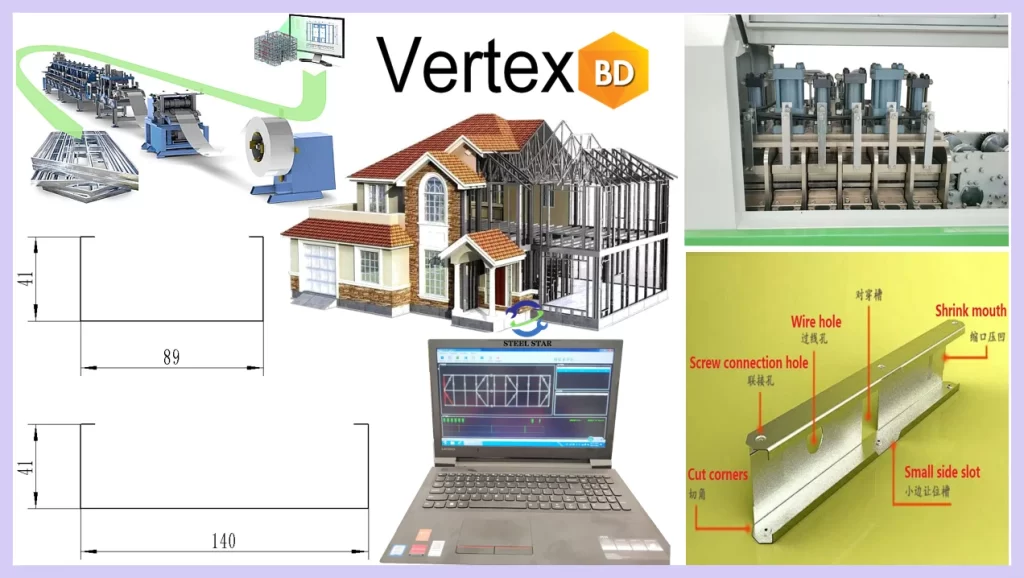

A steel frame machine is an automated roll-forming and fabrication system designed specifically to produce light gauge steel studs, tracks, joists, and trusses. These components are made from high-strength, zinc-coated steel coils, typically ranging from 0.7mm to 2.0mm in thickness. The machine’s evolution from manual punch-and-bend equipment to today’s fully integrated, CNC-driven lines mirrors construction’s own journey toward industrialization and digital fabrication.

The Anatomy of a Modern Steel Frame Machine

A complete framing line is a marvel of sequential engineering:

- Decoiler & Straightener: The process begins with a heavy-duty decoiler holding the raw steel coil, followed by a precision leveling unit that removes any curvature, ensuring a perfectly flat strip of steel enters the system.

- Roll-Forming Mill: The heart of the machine. The flat steel strip passes through a series of progressively shaped rollers. Each station performs a minor bend until the final “C” (stud) or “U” (track) profile is achieved with exceptional consistency. Quick-change roll systems allow a single line to produce multiple profile sizes and types.

- The Punching & Notching Unit: This is where intelligence is embedded. A high-speed, servo-controlled punching unit—guided directly by Building Information Modeling data—precisely punches holes for electrical conduits, plumbing, and mechanical services. It also creates complex web penetrations, end notches for connections, and even pilot holes for screws. This capability for prefabrication is a key value driver, drastically reducing on-site labor and waste.

- Precision Cut-Off: A flying cut system, synchronized with the moving profile, uses hydraulic or servo shears to cut each stud or track to its exact programmed length without stopping the line.

- Automated Stacking & Bundling: Finished components are automatically sorted, aligned, and bundled by wall section or project, ready for direct shipment to the construction site.

The Workflow: From Digital Model to Physical Frame

The machine’s true power is unlocked through software integration:

- Design: An architect or engineer creates a model in Vertex software.

- Optimization: Specialized framing software translates the model into machine instructions. It optimizes material usage, generates cut lists, and details every connection.

- Production: This digital file is sent directly to the machine’s CNC controller. The machine then produces hundreds of unique, labeled components with pinpoint accuracy, ensuring they fit together perfectly on-site like a giant, structural jigsaw puzzle.

Transformative Advantages for Construction

- Speed & Efficiency: A machine can produce a complete house frame in a day, compressing construction timelines by 30-50% and mitigating weather delays.

- Uncompromising Precision & Quality: Components are manufactured to tolerances of less than 1mm, eliminating the inconsistencies of manual labor and ensuring plumb, square, and true walls.

- Material Efficiency & Sustainability: Software-driven nesting minimizes scrap. Steel is 100% recyclable, resistant to rot, pests, and fire, contributing to greener building practices.

- Design Flexibility: Capable of creating complex architectural shapes and long spans that are challenging with traditional materials.

- Labor & Safety Optimization: Shifts skilled labor from the hazardous, weather-dependent construction site to a controlled, safe factory environment, addressing labor shortages.

Applications: Building the Modern World

Steel frame machines produce the primary structural systems for:

- Residential Construction: Low-rise homes, townhouses, and multi-family units.

- Commercial Projects: Hotels, office buildings, schools, and healthcare facilities.

- Ancillary Structures: Mezzanine floors, interior partitions, and roof truss systems.

The Future: Smarter, More Integrated Systems

The next generation of steel frame machines is evolving towards full construction automation:

- IoT & Industry 4.0: Machines equipped with sensors for predictive maintenance and real-time production analytics.

- Robotic Integration: Automated material handling, welding of trusses, and robotic packing to create fully lights-out fabrication cells.

- Advanced Software Connectivity: Deeper, cloud-based integration from architectural BIM through to manufacturing execution systems and on-site augmented reality assembly guides.

The steel frame machine is far more than industrial equipment; it is the physical catalyst for a fundamental shift in how we build. By bridging the digital and physical worlds, it enables a future of construction that is faster, smarter, more sustainable, and less wasteful. It empowers builders to erect durable, resilient structures with the efficiency of manufacturing, making it not just a machine, but a foundational technology for 21st-century architecture. In the quest for better-built environments, the steel frame machine is building the very future, one precise, galvanized stud at a time.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)