Fundamental Manufacturing Processes

Modern steel pipe production employs three primary methods, each requiring specialized machinery and serving different market segments:

1. Seamless Pipe Manufacturing

Seamless pipes, characterized by their uniformity and strength, are produced without welded seams through several specialized processes:

Rotary Piercing (Mannesmann Process)

This century-old technology remains relevant for high-quality seamless pipes:

- Heating Furnaces: Reheat round steel billets to 1,200-1,300°C

- Piercing Mill: Features two barrel-shaped rolls angled in opposing directions that rotate the billet while pushing it over a stationary piercing mandrel

- Elongation: Further reduces wall thickness through mandrel or plug mills

- Sizing: Final dimensional calibration through stretch-reducing or sizing mills

- Modern Advancements: Computer-controlled temperature management and inline ultrasonic testing ensure consistent quality

Extrusion Process

For specialized alloys and difficult-to-work materials:

- Heated billet placed in container with die at opposite end

- Ram applies extreme pressure (up to 12,000 tons) forcing metal through die

- Produces pipes with exceptional dimensional accuracy and surface finish

2. Welded Pipe Manufacturing

Welded pipes account for approximately 65% of global steel pipe production due to their cost-effectiveness and versatility:

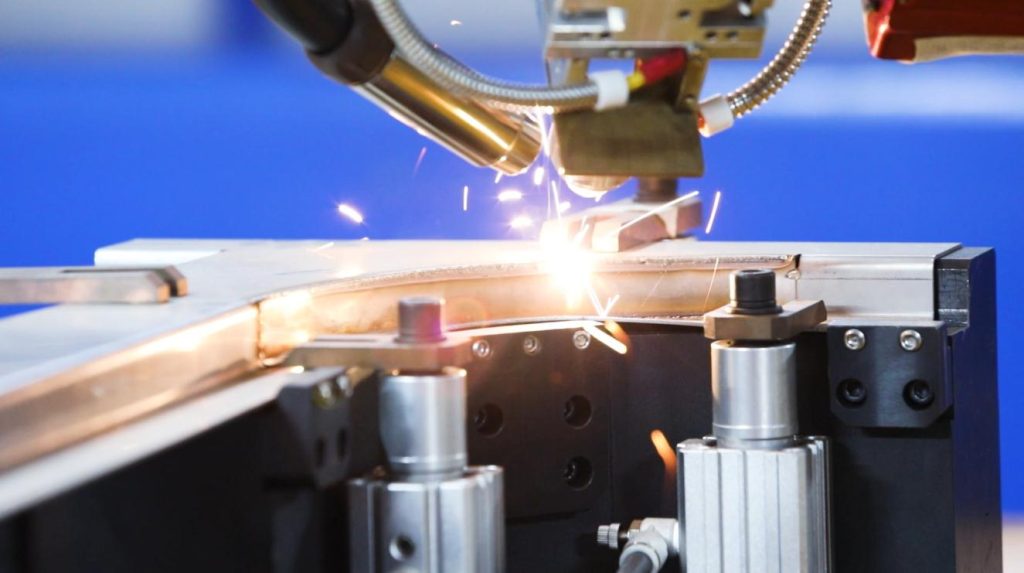

Electric Resistance Welding (ERW)

- Uncoiling and Leveling: Prepares steel coil for processing

- Forming Section: Series of rollers progressively shape flat strip into circular form

- Welding Unit: High-frequency current (100-800 kHz) heats edges to 1,300-1,400°C

- Squeeze Rolls: Forge heated edges together under pressure

- Modern ERW Mills: Operate at speeds up to 200 meters/minute with laser-guided alignment systems

Longitudinal Submerged Arc Welding (LSAW)

For large-diameter pipes (typically 16-64 inches):

- Plate Preparation: Steel plates edge-milled for precise welding

- Forming Presses: U-ing press creates initial shape, O-ing press completes circular form

- Internal/External Welding: Automated welding heads apply multiple passes with flux protection

- Post-Weld Processing: Normalizing, expanding, and hydrostatic testing

Spiral Welded Pipe Manufacturing

Produces large-diameter pipes from narrower coils:

- Continuous Forming: Strip fed at controlled angle to create spiral geometry

- Multi-Head Welding: Simultaneous internal and external welding

- Cutting System: Flying saws cut pipes to length while in motion

Comprehensive Machine Components and Systems

Modern pipe manufacturing lines integrate numerous specialized machines:

Material Preparation Section

- Coil Handling Systems: Heavy-duty cranes, coil cars, and upenders for material logistics

- Decoiling Machines: Motorized uncoilers with tension control systems

- Leveling Equipment: Multi-roller levelers removing coil curvature and imperfections

- Edge Trimming: Rotary shear systems for precise width control

- Surface Treatment: Shot blasting and chemical cleaning for weld quality

Forming and Welding Section

- Progressive Roll Forming Stations: 6-12 stands with precisely contoured rolls

- High-Frequency Welding Generators: Solid-state systems with 400-600 kW capacity

- Impedance Systems: Vee contacts or induction coils for current delivery

- Weld Trimming: Internal and external bead removal systems

- Real-Time Monitoring: Infrared thermography and ultrasonic weld inspection

Finishing and Processing Section

- Sizing Mills: 4-6 stand reducing mills for final dimensional accuracy

- Straightening Machines: Multi-roll crossbow or rotary straighteners

- Cutting Systems: Flying saws with carbide-tipped blades or plasma cutters

- Heat Treatment: Normalizing furnaces and quenching systems

- Surface Coating: Galvanizing, painting, or epoxy application lines

Testing and Quality Control

- Non-Destructive Testing (NDT):

- Ultrasonic testing for wall thickness and defect detection

- Eddy current testing for surface flaws

- X-ray and gamma-ray inspection for weld integrity

- Hydrostatic testing to 1.5-2 times operating pressure

- Dimensional Verification: Laser profilometers and automated caliper systems

- Material Certification: Spectroscopic chemical analysis and mechanical testing

Technological Specifications and Performance Metrics

Modern pipe manufacturing machines exhibit impressive capabilities:

Production Capacity

- Speed: ERW lines operate at 30-200 m/min depending on diameter

- Diameter Range: 0.5 mm capillary tubes to 4,000 mm large-diameter pipes

- Wall Thickness: 0.1 mm to 100+ mm for specialized applications

- Annual Output: Single lines produce 50,000-500,000 tons annually

- Material Utilization: Advanced lines achieve 97-99% yield rates

Precision Standards

- Diameter Tolerance: ±0.5% for standard pipes, ±0.1% for precision applications

- Wall Thickness Control: ±5-7.5% for standard grades

- Straightness: 0.2-1.0 mm per meter depending on application

- Surface Finish: Ra 0.8-6.3 μm for most industrial applications

Industry Applications and Specialized Requirements

Different applications demand specialized manufacturing approaches:

Energy Sector

- Oil and Gas Transmission: API 5L specification pipes with stringent toughness requirements

- Drilling Applications: Heavy-walled, high-strength grades for challenging environments

- Refinery Piping: High-temperature and corrosion-resistant alloys

Construction and Infrastructure

- Structural Applications: ASTM A500 rectangular and circular sections

- Piling: Large-diameter, thick-walled pipes for foundation support

- Scaffolding: Lightweight, high-strength galvanized pipes

Mechanical and Process Applications

- Boiler Tubes: Precision seamless pipes for high-pressure applications

- Hydraulic Systems: Seamless tubes with precise dimensional control

- Automotive: Exhaust systems, fuel lines, and structural components

Specialized Applications

- Nuclear Power: Ultra-clean steel with exacting quality requirements

- Subsea Applications: Corrosion-resistant, heavy-wall pipes for deepwater

- Geothermal: High-temperature alloys for aggressive environments

Automation and Industry 4.0 Integration

Modern pipe mills increasingly incorporate digital technologies:

Smart Manufacturing Systems

- Digital Twins: Virtual replicas of manufacturing lines for optimization

- Predictive Maintenance: Vibration analysis and thermal monitoring preventing failures

- Automated Quality Control: Machine vision systems detecting surface defects

- Energy Management: Optimizing power consumption across operations

Process Control Advancements

- Adaptive Forming: Real-time roll adjustment based on material feedback

- Intelligent Welding: Self-adjusting parameters based on joint conditions

- Robotic Handling: Automated material transfer and packaging

- Data Integration: Complete traceability from raw material to finished product

Environmental Considerations and Sustainability

Contemporary pipe manufacturing prioritizes environmental responsibility:

Resource Efficiency

- Energy Recovery: Recapturing heat from furnaces and cooling systems

- Water Recycling: Closed-loop systems minimizing freshwater consumption

- Material Optimization: Advanced nesting software reducing scrap generation

- Byproduct Utilization: Processing mill scale and slag for other industries

Emission Control

- Fume Extraction: Advanced filtration capturing welding and cutting emissions

- Noise Reduction: Acoustic enclosures and vibration dampening

- Waste Management: Systematic handling of oils, chemicals, and process waste

Economic and Operational Considerations

Pipe manufacturing represents significant capital investment with specific economic dynamics:

Capital Investment

- Greenfield Facilities: $100-500 million depending on capacity and technology

- Modernization Projects: $20-100 million for technology upgrades

- Payback Period: Typically 5-8 years for well-positioned facilities

Operational Economics

- Raw Material Costs: 60-75% of total production cost

- Energy Consumption: 8-15% of operational costs

- Labor Component: 5-12% depending on automation level

- Maintenance Costs: 3-6% of capital investment annually

Global Market and Regional Specialization

The pipe manufacturing industry exhibits distinct regional characteristics:

Leading Manufacturing Regions

- China: World’s largest producer with extensive welded pipe capacity

- Europe: Technology leader in high-value seamless and precision pipes

- North America: Strong in oil country tubular goods and large-diameter pipes

- Japan and South Korea: Advanced materials and automated production

Market Dynamics

- Global Production: Approximately 180 million tons annually

- Growth Drivers: Infrastructure development, energy transitions, urbanization

- Competitive Factors: Technology, quality, logistics, and value-added services

Future Trends and Innovations

The pipe manufacturing industry continues to evolve through several key trends:

Advanced Materials Processing

- Higher Strength Grades: X100+ pipeline steels and advanced alloys

- Composite Solutions: Steel-polymer-steel laminate pipes for corrosion resistance

- Smart Pipes: Embedded sensors for structural health monitoring

- Lightweight Solutions: Advanced manufacturing enabling thinner walls with maintained strength

Manufacturing Technology Evolution

- Additive Manufacturing: 3D printing of complex pipe fittings and components

- Laser-Based Processes: Laser welding and hybrid manufacturing approaches

- Sustainable Technologies: Hydrogen-based heating and carbon capture integration

- Modular Design: Flexible manufacturing systems adapting to changing demands

Digital Transformation

- Artificial Intelligence: Optimizing production parameters and predictive quality control

- Blockchain: Secure material traceability and quality documentation

- Augmented Reality: Maintenance assistance and operator training

- Cloud Integration: Remote monitoring and centralized process optimization

Challenges and Opportunities

The industry faces several significant challenges alongside substantial opportunities:

Technical Challenges

- Material Consistency: Managing variations in steel chemistry and properties

- Energy Intensity: Reducing carbon footprint while maintaining competitiveness

- Skill Requirements: Developing workforce for increasingly complex technology

- Regulatory Compliance: Meeting evolving environmental and safety standards

Market Opportunities

- Energy Transition: Pipes for hydrogen, carbon capture, and renewable energy

- Infrastructure Renewal: Replacement of aging water and gas distribution networks

- Emerging Markets: Urbanization driving demand in developing economies

- Value-Added Services: Engineering, coating, and fabrication services

Steel pipe manufacturing machines represent a remarkable convergence of mechanical engineering, materials science, and digital technology. From the massive scale of spiral welded mills producing 4-meter diameter pipelines to the precision of capillary tube mills operating at microscopic tolerances, this industry demonstrates extraordinary technical sophistication.

The continuous evolution of pipe manufacturing technology—from manual processes to today’s fully automated, digitally integrated systems—reflects broader industrial advancement. As global challenges in infrastructure, energy, and sustainability intensify, the importance of efficient, reliable pipe manufacturing will only increase.

Future developments will likely focus on greater sustainability through reduced energy consumption and material usage, enhanced digital integration enabling unprecedented quality and efficiency, and advanced materials meeting increasingly demanding application requirements. The steel pipe manufacturing machine, in its many forms, will continue to serve as a fundamental enabler of modern civilization—transporting essential resources, supporting structures, and facilitating industrial processes that underpin economic development and quality of life worldwide.

In an era of rapid technological change, the pipe manufacturing industry demonstrates how traditional heavy industry can successfully embrace innovation while maintaining its essential role in the global economy. The machines that transform raw steel into precisely engineered pipes remain critical infrastructure in their own right—the backbone supporting countless other industries and applications that define the modern world.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)