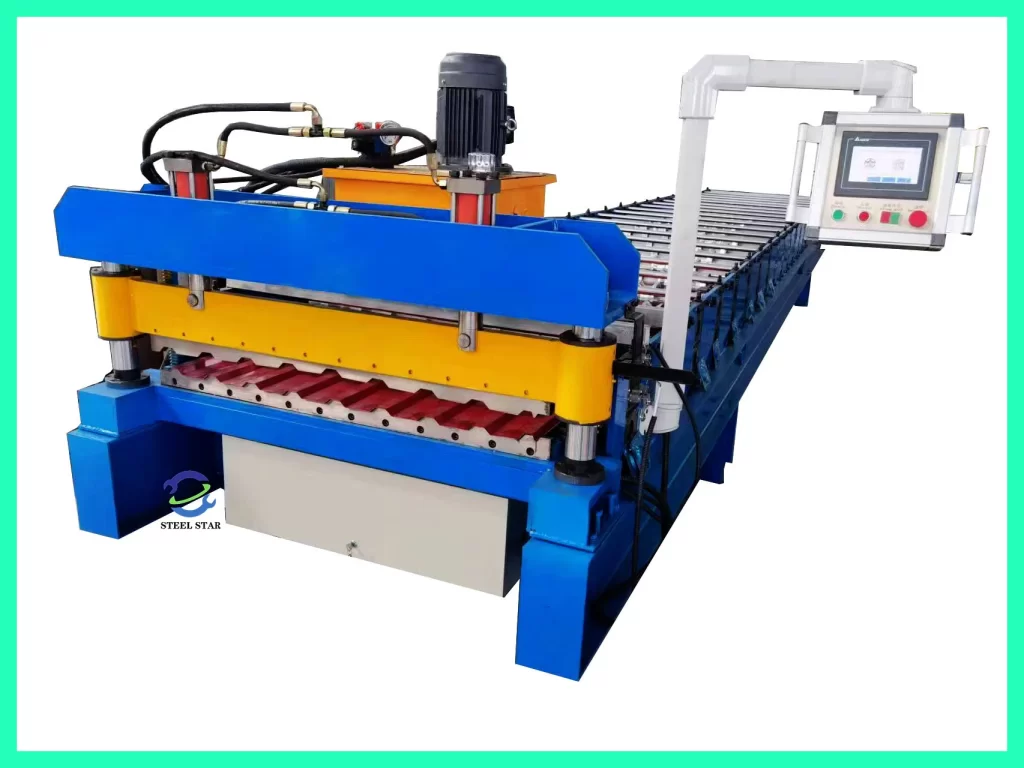

A Metal Roof Making Machine, also known as a Steel Roof Machine or Metal Roofing Machine, is specialized industrial equipment used to manufacture metal roofing sheets. These machines play a crucial role in producing durable and customizable roofing panels for various types of construction. Below are some key details:

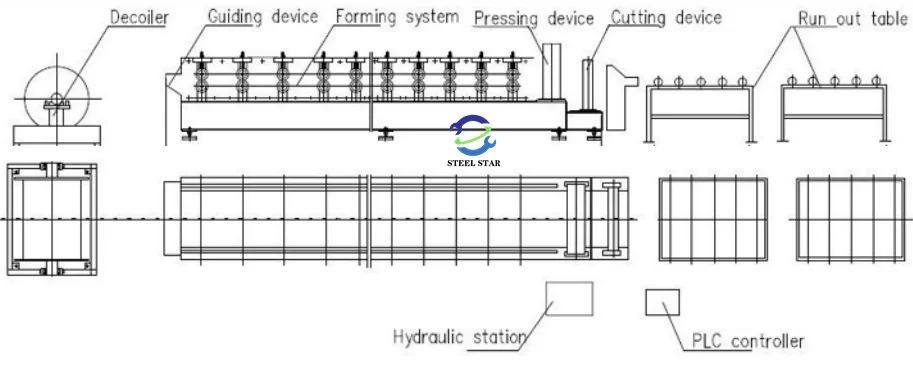

1. Features and Components:

- Decoiler: Holds and unwinds large metal coils for feeding into the machine.

- Roll Forming Unit: Composed of multiple rollers that progressively shape the flat metal sheet into a specified profile, such as corrugated, standing seam, or trapezoidal shapes.

- Hydraulic Cutting System: Precisely cuts the panels to desired lengths without distorting the profile.

- Control Panel: Often equipped with a PLC (Programmable Logic Controller) for automated control, allowing operators to set parameters such as panel length and quantity.

- Output Conveyor/Table: Where the completed panels are deposited for collection.

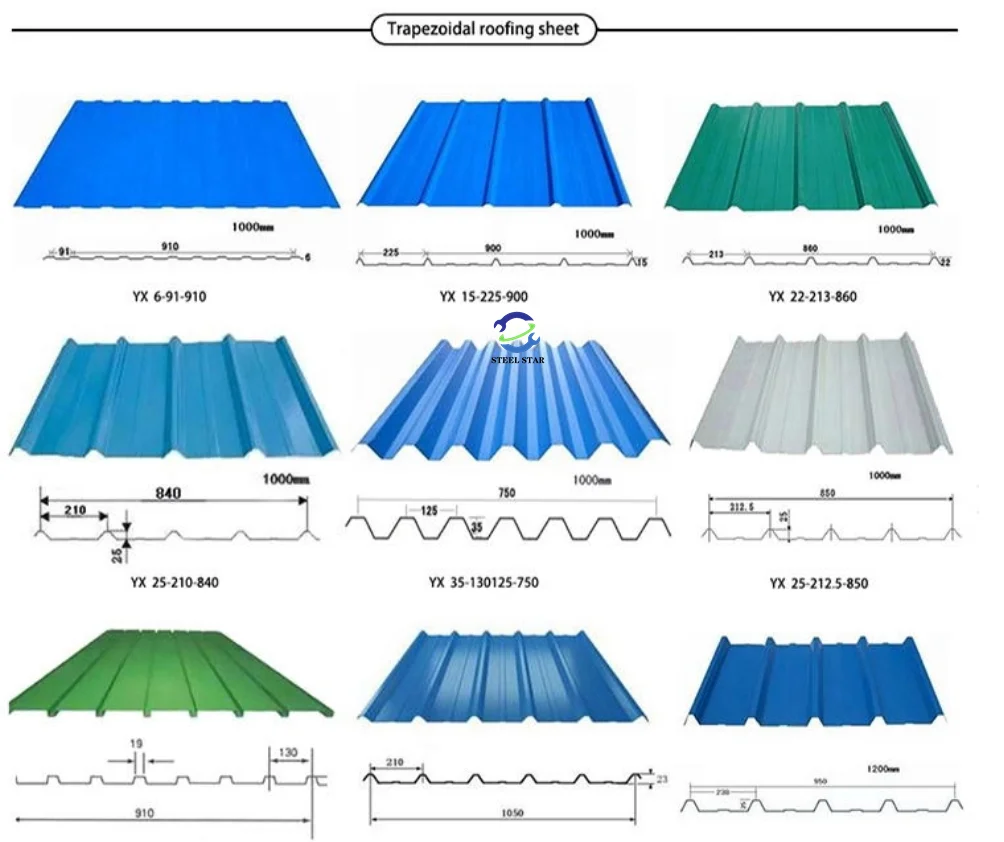

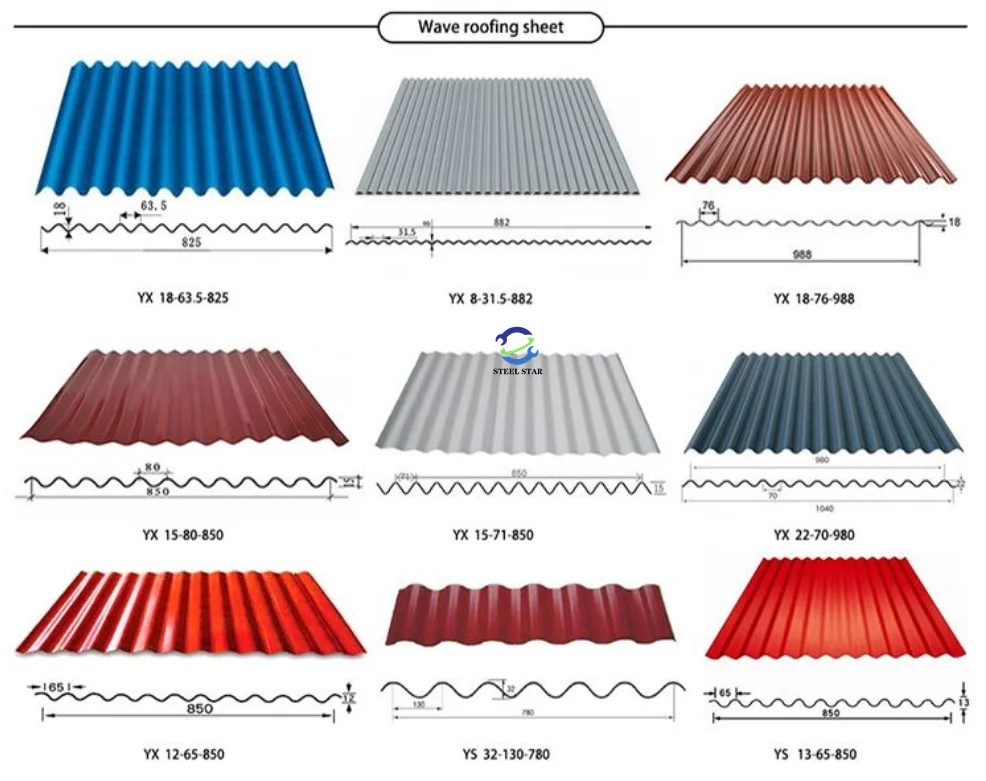

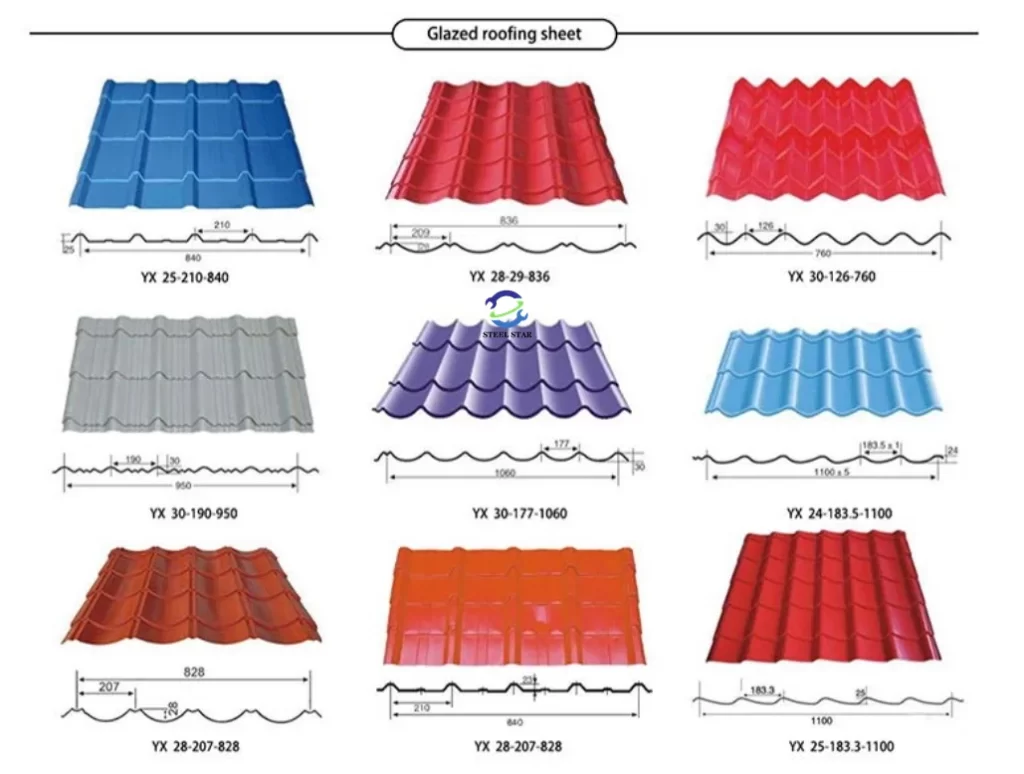

2. Types of Roof Profiles Created:

- Standing Seam Panels: Ideal for modern roofing, known for durability and weather resistance.

- Corrugated Sheets: Characterized by a wavy pattern that offers structural integrity and traditional appearance.

- Trapezoidal Panels: Feature an angular shape that provides strong load-bearing capacity.

- Tile Effect Profiles: Mimic the appearance of traditional roof tiles but are made from metal for enhanced longevity.

3. Benefits of Using Metal Roofing Machines:

- High Precision: Ensures consistent production with minimal variation.

- Automation: Reduces manual labor and increases production speed, enhancing overall efficiency.

- Versatility: Can produce panels in various lengths and designs as needed.

- Durability: The resulting roofing panels are resistant to corrosion and can withstand harsh weather conditions.

- Cost-Effective: Reduces waste material and boosts productivity.

4. Common Applications:

- Commercial Buildings: Factories, warehouses, and commercial complexes.

- Residential Projects: Houses, condominiums, and apartment buildings.

- Agricultural Constructions: Barns, storage units, and livestock shelters.

- Industrial Facilities: Workshops and production halls.

5. Additional Features and Options:

- Embossing Units: To create texture or patterns on the metal sheets.

- Automatic Stacker: To organize finished panels for easy collection.

- Custom Die Options: For creating unique panel designs tailored to specific requirements.

Roof panel products equipment can be customized in various sizes:

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)