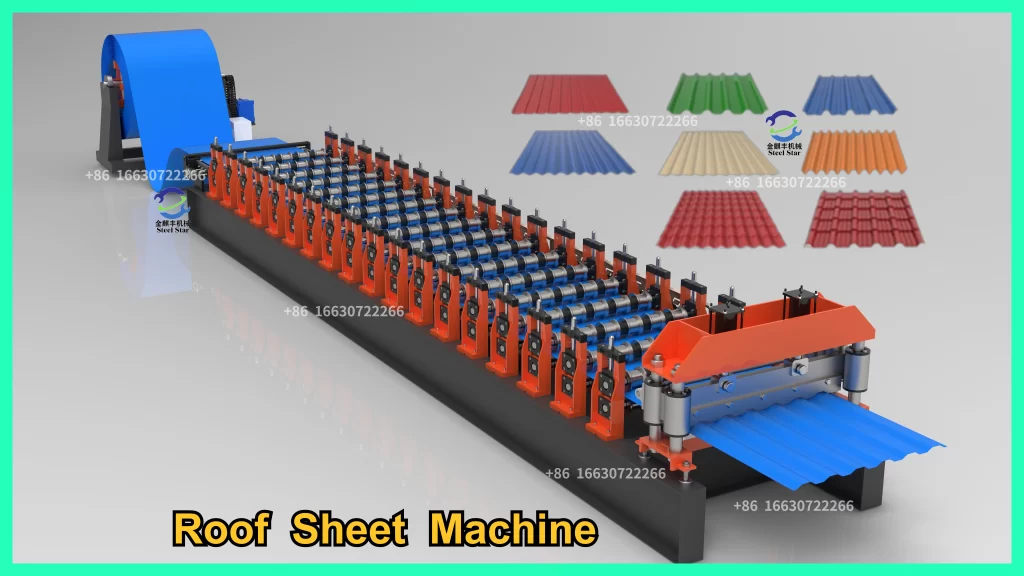

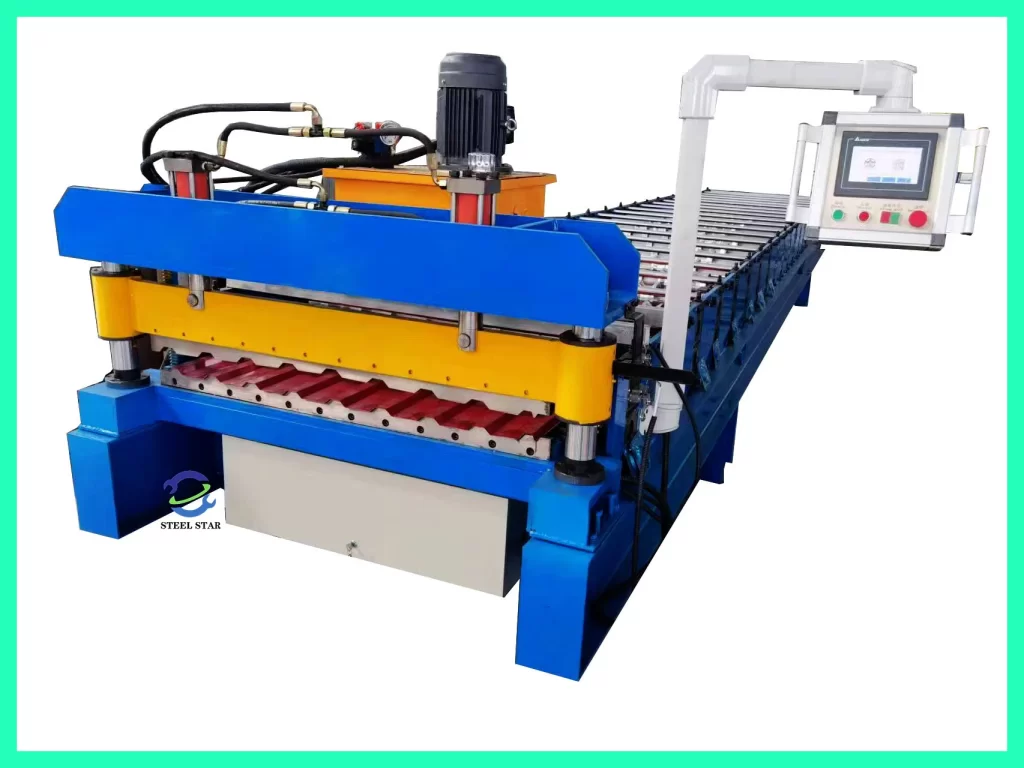

Steel roofing machine and metal roofing machine are specialized equipment used to manufacture metal roof panels and tiles. These machines are designed to create different types of metal roofing sheets, such as standing seam panels, corrugated panels, and trapezoidal panels. Here’s a breakdown of how they work and what they do:

1. Components of Metal Roofing Machines:

- Decoiler: Feeds the metal coil into the machine.

- Roll Forming System: Consists of a series of rollers that gradually shape the flat metal coil into the desired profile.

- Cutting Mechanism: A hydraulic or mechanical cutter trims the metal panels to the required length.

- Control System: Often equipped with a programmable logic controller (PLC) for automation and precision control.

- Output Table: Holds the finished roofing sheets.

2. Types of Roofing Profiles Produced:

- Standing Seam Panels: Provide a sleek, waterproof look ideal for modern structures.

- Corrugated Panels: Known for durability and used in both residential and industrial buildings.

- Trapezoidal Panels: Offer strong structural support and are used in various construction projects.

3. Advantages of Using Metal Roofing Machines:

- Efficiency: High production speed and consistency.

- Customization: Can produce panels of various lengths, widths, and profiles.

- Cost-Effectiveness: Reduces the need for manual labor and ensures precision, minimizing material waste.

- Durability: Produces panels that are resistant to harsh weather conditions and corrosion.

4. Applications:

- Commercial Buildings: Warehouses, factories, and shopping centers.

- Residential Roofing: Homes and apartment complexes.

- Agricultural Structures: Barns and storage facilities.

These machines are valuable investments for roofing manufacturers or construction companies looking to produce their own metal roofing materials with high quality and consistency.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)