The Precision Engine of Modern Steel Supply: An In-Depth Look at Steel Slitting Machines

Beneath the organized efficiency of metal fabrication shops and service centers lies a critical process that transforms raw material inventory into usable product: the precision slitting of wide steel coils into narrower strips. This fundamental operation is performed by a sophisticated piece of industrial equipment—the Steel Slitting Machine. As the indispensable gateway between mill production and downstream manufacturing, this machine ensures material flows efficiently through the global supply chain, delivering the exact specifications required by countless industries.

Core Function and Operational Principle

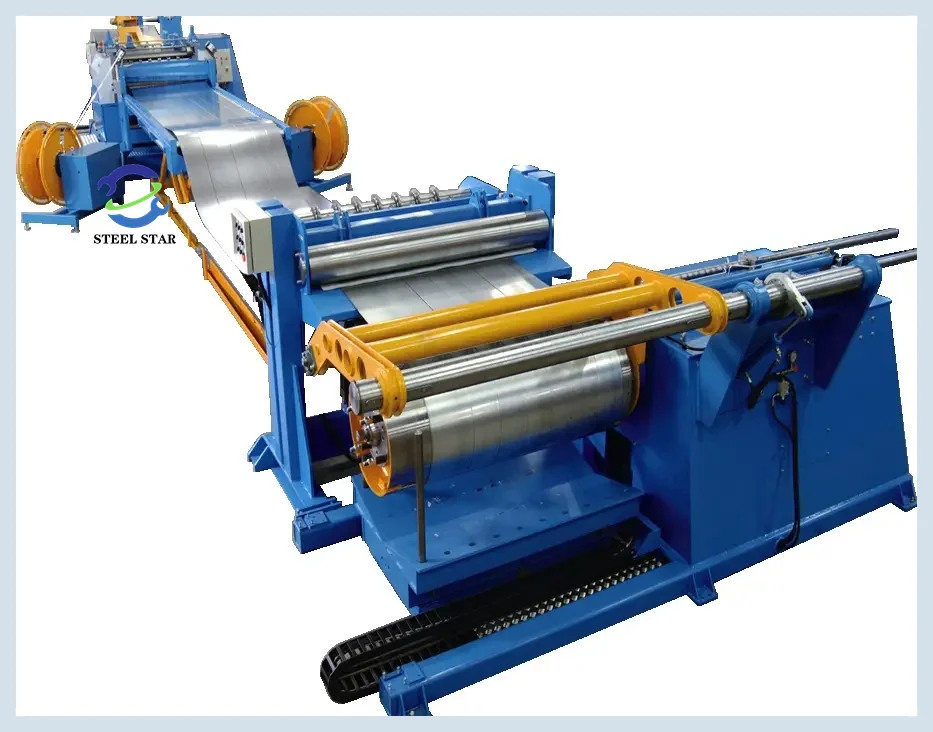

A steel slitting machine (or slitter) is a high-precision, semi-continuous or continuous processing line designed to longitudinally shear a wide master steel coil into multiple, narrower strips of predetermined widths. The process maintains the original coil’s thickness, coating (e.g., galvanized, painted), and metallurgical properties while dramatically increasing its utility.

The standard operational sequence is methodical and precise:

- Loading & Feeding: A heavy master coil, often weighing 10-30 tons, is loaded onto a powered mandrel uncoiler. The leading edge is fed into the machine entry section.

- Pre-Slit Leveling: The material passes through a multi-roll leveler. This critical step removes coil set, crossbow, and edge wave, ensuring perfectly flat material enters the cutting section—a prerequisite for achieving consistent strip width and edge quality.

- The Slitting Head: The heart of the machine. The coil passes through a stacked set of hardened steel rotary knives:

- Top and Bottom Arbors: These are shafts that hold the circular slitting knives. The precise spacing of these knives on the arbors, determined by spacers and shims, dictates the final strip widths.

- Side Trimmers: Positioned on the outside edges to cleanly remove damaged or irregular coil edges before slitting.

- Separation & Recoiling: After the longitudinal cuts are made, the resulting strips must be separated to prevent interlocking. This is achieved using a “thread-up” system with divider plates or tip guides. The individual strips are then independently wound onto separate tension mandrels on the dual-head or multi-head recoiler, forming tight, uniform “slit” coils.

- Control & Scrap Handling: The entire process is managed by a Programmable Logic Controller (PLC) that coordinates line speed, tension, and edge guidance. A scrap chopper system typically cuts the side trim into manageable pieces for recycling.

Key Components and Technological Sophistication

- Uncoiler with Tension Braking: Provides controlled, variable back-tension to prevent material looping and ensure a stable feed.

- Precision Leveler: Essential for processing high-strength steels and coated materials, equipped with adjustable rolls to counteract specific flatness defects.

- Slitting Head Configuration: Machines are categorized by their knife arbor design. Loop-type (Pull-Through) slitters are common for thinner gauges, while Double Arbor slitters offer superior precision and are standard for most modern, high-volume applications.

- Tooling (Knives & Spacers): The quality of the machined, hardened slitter knives and the precision-ground spacers directly determines cut edge quality, tool life, and dimensional accuracy. Clearance between top and bottom knives is meticulously set based on material thickness and grade.

- Tension Recoiler: A central component that uses either a center-wind (with tension control) or a surface-wind drive to build tightly wound, cylindrical slit coils without telescoping.

The Transformative Advantages of Precision Slitting

- Supply Chain Efficiency: Allows service centers to stock a wide range of widths from standard master coils, dramatically reducing customer lead times and inventory costs for end-users.

- Material Yield Optimization: Precise width control minimizes edge trim loss, maximizing usable material from expensive master coils.

- Edge Quality Superiority: Rotary slitting produces a cleaner, more consistent edge than traditional shear cutting, often eliminating the need for secondary edge finishing in stamping, roll forming, or tube production.

- Productivity: Modern lines can process coils at speeds exceeding 600 meters per minute, offering unparalleled throughput for high-volume consumers.

Applications and Industry Impact

Slit coils are the essential feedstock for a vast array of manufacturing processes:

- Roll Forming: For producing roofing panels, wall cladding, purlins, and structural sections.

- Tube & Pipe Mills: As the raw material for both welded and seamless tube production.

- Stamping & Blanking Presses: Supplying precision-width coils for automotive parts, appliances, and electrical components.

- Building Materials: Creating strapping, framing components, and trim.

Evolution and Future Trends

Technology continues to advance the capabilities of the modern slitting line:

- Automated Width Change (AWC): Systems using robotic arms or servo-driven carriages to change spacers and knife setups automatically, drastically reducing changeover time from hours to minutes.

- Advanced Measurement & Control: Integration of laser width gauges, optical edge guidance systems, and in-line surface inspection cameras for 100% quality verification.

- IoT & Predictive Analytics: Sensors monitor knife wear, arbor vibration, and hydraulic pressure, enabling predictive maintenance and minimizing unplanned downtime. Production data is fed into central Manufacturing Execution Systems (MES).

- Handling Advanced Materials: Adaptations to handle the increasing demands of ultra-high-strength steels (UHSS), aluminum alloys, and sophisticated coated products without damaging the surface.

The steel slitting machine is far more than a simple cutter; it is a precision instrument of material optimization and supply chain fluidity. It bridges the gap between the massive scale of steel mill production and the specific, varied needs of downstream manufacturers. By delivering material with exact width, superior edge quality, and impeccable consistency, it forms the critical first step in countless value-added processes. In an industry where precision and efficiency define competitiveness, the modern slitting line stands as a foundational technology, quietly ensuring that the right material is in the right place, at the right time, and in the right form to build the modern world.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)