Steel Star Roof Panel Machine: Precision Engineering for Superior Building Envelopes

In the construction industry, the quality, efficiency, and durability of roofing systems are paramount. The machinery that produces these critical components must therefore operate with unwavering precision and reliability. The Steel Star Roof Panel Machine stands as a benchmark in this field, engineered to transform high-strength steel coils into perfectly formed, consistent roof panels with exceptional speed and accuracy. This article explores the core features, technological advantages, and tangible benefits that make this machine a preferred choice for manufacturers worldwide.

Core Design Philosophy: Built for Performance and Durability

Steel Star engineers each roof panel machine with a singular focus: to be the most reliable and productive asset on a client’s factory floor. The design philosophy centers on three pillars:

- Structural Robustness: The machine frame is constructed from heavy-duty, reinforced steel to withstand the constant stresses of high-volume production. This ensures long-term stability, minimizes vibration, and guarantees consistent panel geometry year after year.

- Production-Centric Efficiency: Every component, from the uncoiler to the final cut-off system, is optimized for minimal downtime. Features like quick-change tooling systems allow for rapid profile switches, while servo-controlled precision cutting eliminates material waste.

- User-Focused Operation: Intuitive controls and accessible design simplify operation and routine maintenance, reducing skill barriers and ensuring smooth daily workflow.

Key Technological Features and Components

A Steel Star Roof Panel Machine is a synchronized system where each part plays a vital role in the final output quality.

- High-Precision Forming Stations: The heart of the machine. Each forming roll is machined from premium alloy steel and undergoes precise heat treatment for extended wear resistance. The stations are meticulously aligned to progressively shape the metal without stretching or marring the surface, ensuring a flawless finish on pre-painted or galvanized coils.

- Advanced Cutting System: Equipped with a high-performance hydraulic or servo flying cut-off system, the machine delivers clean, burr-free cuts at full line speed. The length control is digitally managed, providing absolute accuracy for every panel, which is critical for on-site installation efficiency and material cost control.

- Intelligent Control Center: A centralized PLC-based control panel, often featuring a user-friendly touchscreen HMI (Human-Machine Interface), allows operators to manage all parameters—speed, length, count, and diagnostic data—from a single station. This enables precise control and quick troubleshooting.

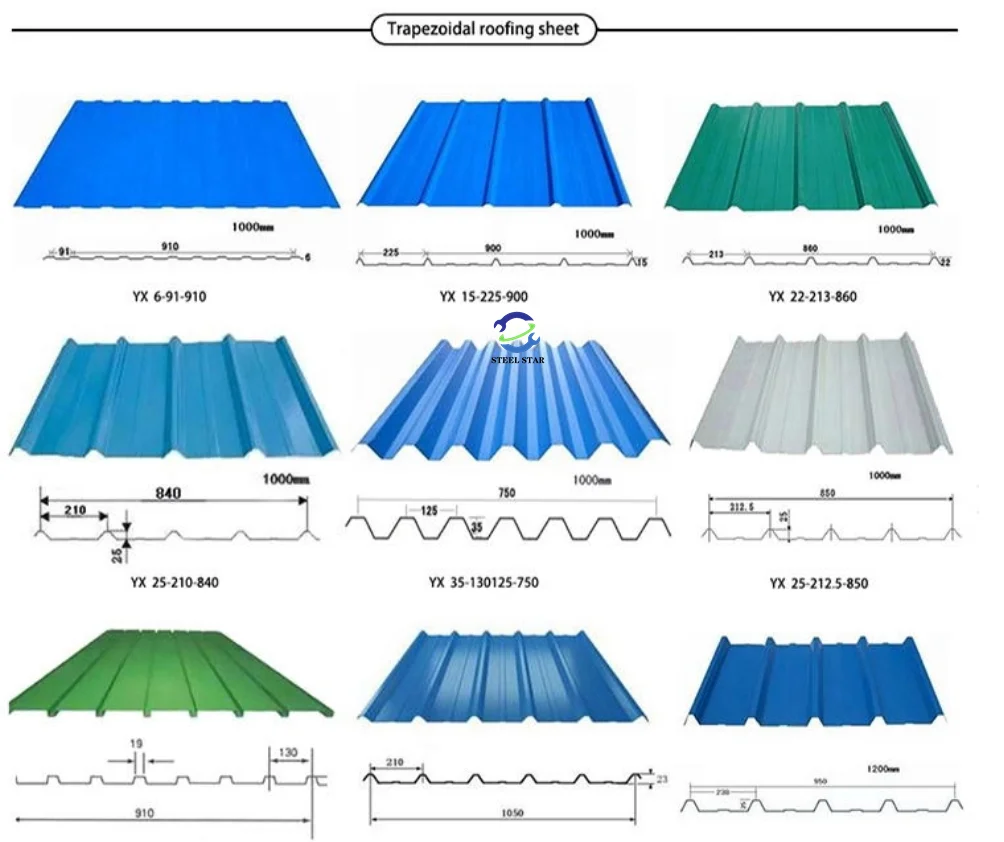

- Customization for Diverse Profiles: Steel Star machines are not one-size-fits-all. They are engineered to produce a wide range of industry-standard and custom roof profiles, including versatile standing seam panels, classic corrugated sheets, and trapezoidal designs, catering to various architectural and climatic requirements.

Tangible Benefits for Manufacturers

Investing in a Steel Star machine translates directly into competitive advantages for panel producers:

- Unmatched Output Quality: Produces panels with consistent dimensions, tight seals, and excellent structural integrity, leading to superior performance in weather resistance and longevity.

- High Production Speed & Yield: Maximizes output per shift and significantly reduces material waste through precise forming and cutting, directly improving profitability.

- Operational Reliability: The robust build and quality components ensure high uptime, predictable maintenance schedules, and a long operational lifespan, protecting the capital investment.

- Technical and After-Sales Support: Steel Star provides comprehensive support, from installation and training to ongoing technical assistance and readily available spare parts, ensuring uninterrupted production.

For contractors and building owners, a roof is the first line of defense against the elements. For the manufacturer producing that roof, the machinery is the foundation of their business integrity. The Steel Star Roof Panel Machine embodies this principle. It is more than just equipment; it is a precision tool engineered to deliver products that builders trust and that stand the test of time. By combining robust construction, advanced technology, and a deep understanding of industry needs, Steel Star provides manufacturers with the capability to excel, making it a defining choice in the global market for roofing solutions.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)