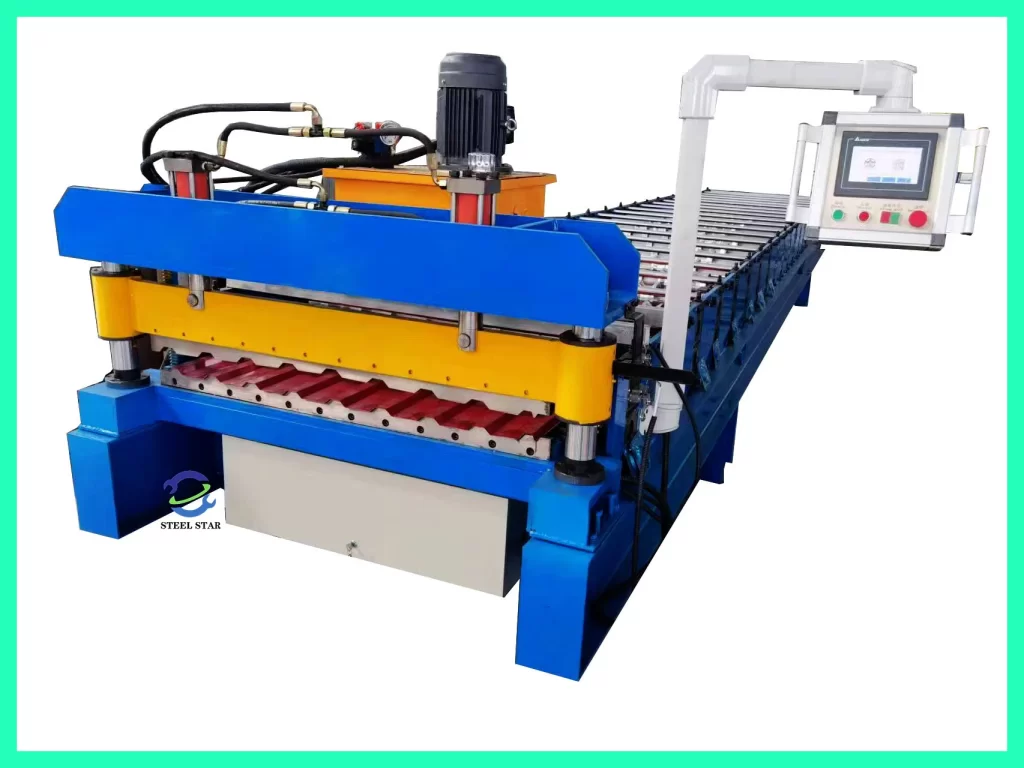

The Wall Panel Roll Forming Machine and the Wall Sheet Roll Forming Machine are both industrial machines used in the construction industry for manufacturing metal cladding materials. While they serve similar purposes, there are distinctions in their applications, the types of profiles they create, and their uses in building construction.

1. Wall Panel Roll Forming Machine

- Purpose: Specifically designed for creating structured wall panels, these machines produce high-strength, shaped panels that are typically used for wall cladding in commercial, industrial, and sometimes residential buildings.

- Profiles Produced: Wall panel roll forming machines create deeper, more complex profiles, like ribbed, standing seam, or interlocking panels. These panels add both structural support and aesthetic appeal.

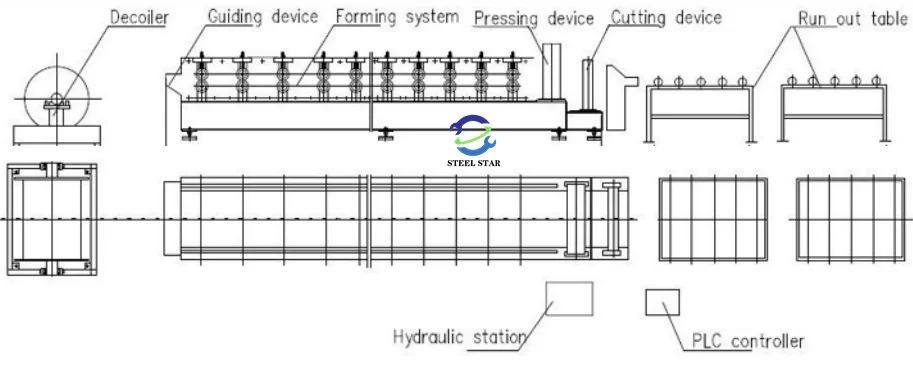

- Features:

- Complex Roller Systems: Engineered to shape metal sheets into precise, load-bearing profiles.

- Adjustable Settings: Often capable of producing multiple types of panel profiles from a single machine.

- Precision Cutting: Includes automated cutting systems for producing customized panel lengths.

- Applications:

- Exterior and Interior Walls: Wall panels offer weather resistance and aesthetic options for external walls and are sometimes used for interior partitioning.

- Roof Panels: Some machines also produce roofing panels, making them versatile for construction needs.

2. Wall Sheet Roll Forming Machine

- Purpose: Used to manufacture simpler metal wall sheets, primarily for cladding large areas. These sheets are suitable for covering broad wall and roof surfaces in industrial or agricultural buildings.

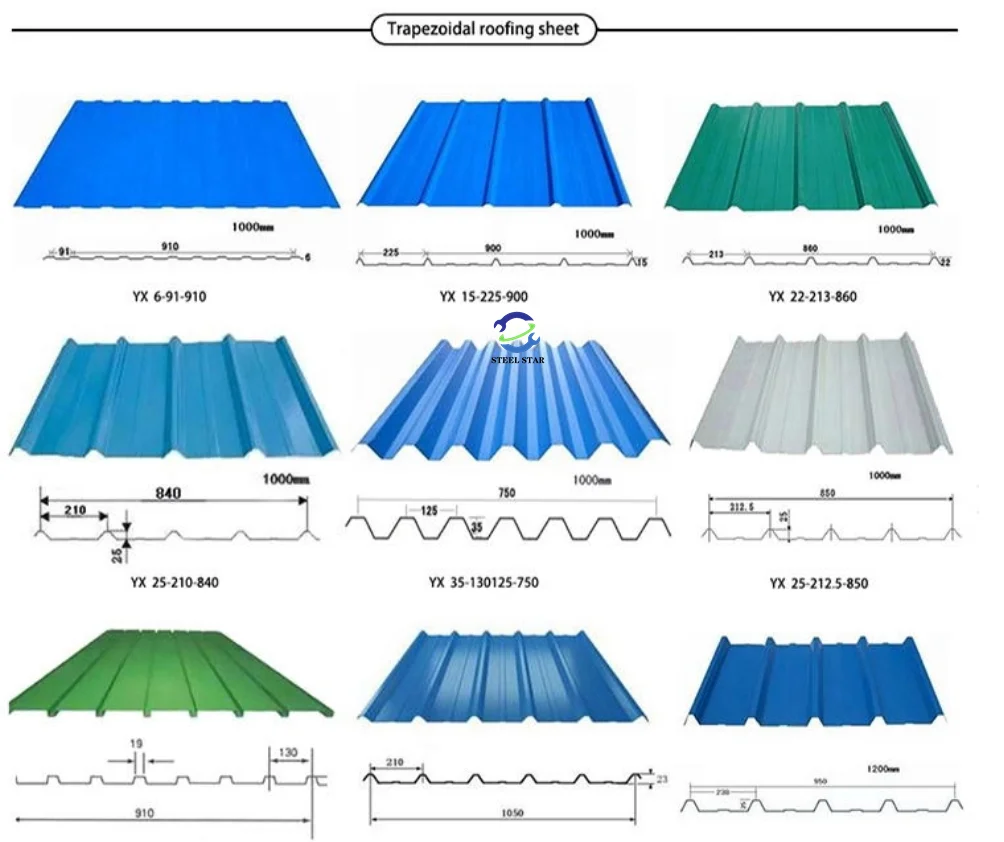

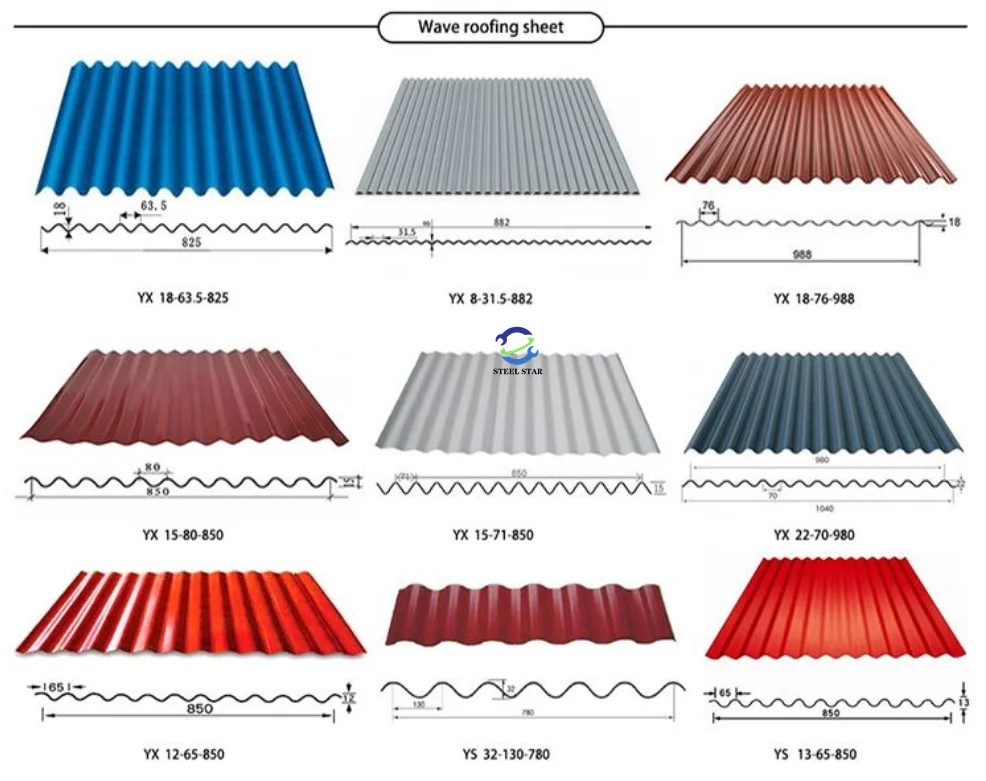

- Profiles Produced: Common profiles include corrugated, trapezoidal, or wave-like patterns, which are primarily designed for coverage rather than structural support.

- Features:

- Straightforward Roller System: Focused on shaping metal sheets into wide, often shallow, profiles.

- Wide Coverage Design: Designed to create sheets that cover larger surface areas, making it efficient for mass production.

- Automatic Cutting: Equipped with precise cutting mechanisms for consistent sheet length.

- Applications:

- Exterior Wall and Roof Cladding: Wall sheets are ideal for covering large areas, offering a balance between weather resistance and lightweight construction.

- Agricultural Buildings: Frequently used in barns, warehouses, and storage facilities where durability and cost-efficiency are priorities.

Key Differences

- Profile Depth and Complexity: Wall panel machines produce deeper, structurally supportive profiles, while wall sheet machines create simpler profiles for broad coverage.

- Aesthetic Options: Wall panels often come with more architectural design options, whereas wall sheets are typically functional and focus on coverage.

- Application Scope: Wall panels are used in both high-end and functional structures, while wall sheets are commonly used in industrial and agricultural settings.

Both machines provide durable, weather-resistant solutions for construction but cater to slightly different needs based on design and structural requirements.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)