The Welded Pipe Making Machine: A Pillar of Modern Industry

From the water flowing through our taps to the oil and gas traversing continents, and the structural frames of towering buildings, welded steel pipes are the silent, essential arteries of modern civilization. At the heart of their production lies a marvel of industrial engineering: the Welded Pipe Making Machine. This sophisticated equipment transforms flat steel strips into strong, continuous tubes through a process that blends precision, force, and heat.

Core Principle: From Strip to Tube

The fundamental operation of a welded pipe mill is a continuous, high-speed process. It takes a coil of steel strip (skelp), forms it into a cylindrical shape, and then creates a permanent longitudinal seam along its length using welding. The specific method of forming and welding defines the machine’s primary type.

Key Types and Their Processes

Welded pipe machines are primarily categorized by the welding technique employed, each suited for different diameters, thicknesses, and applications.

1. ERW (Electric Resistance Welding) Mill

This is the most common type for pipes in the range of approximately ½ inch to 24 inches in diameter.

- Process: The formed strip edges are brought together under pressure. A high-frequency electrical current (AC or DC) is passed through the edges. The resistance to the current generates intense, localized heat, bringing the steel to a forging temperature. The pressure then forges the edges together without filler metal, creating a seamless bond.

- Machine Components: Uncoiler, forming section (with a series of cage rolls), high-frequency welder, cooling system, sizing section (to calibrate diameter), and cutting saw.

- Applications: Water and gas distribution, structural tubing, automotive components, and mechanical engineering.

2. SAW (Submerged Arc Welding) Mill

Used for large-diameter, thick-walled pipes (typically from 16 inches up to over 60 inches), essential for major infrastructure.

- Process: The pipe is formed using a series of rollers (U-O-E process: U-ing, O-ing, Expansion) or a cage former. Welding is performed on the inside and outside using an electric arc under a blanket of granular flux, which prevents contamination and allows for deep weld penetration. Filler wire is used.

- Machine Components: Heavy-duty plate edge mill, pre-forming press, U-ing press, O-ing press, internal/external SAW stations, expanding machine, and end-finishing stations.

- Applications: Oil and gas transmission pipelines, piling, offshore structures, and wind turbine monopiles.

3. HFI (High-Frequency Induction) Welding Mill

A subset of ERW, it uses an induction coil to generate the heating current without physical contact with the pipe, offering very clean, precise welds for high-specification tubing.

- Applications: Automotive fuel and brake lines, heat exchanger tubes, and hydraulic cylinders.

The Anatomy of a Modern Pipe Mill

A complete welded pipe making line is a symphony of integrated stations:

- Entry & Preparation: Uncoilers, shears for coil joining, and a live accumulation loop ensure continuous material flow.

- Forming Section: The heart of shaping. A series of precisely contoured rolls progressively bend the flat strip into an open-seam circular profile.

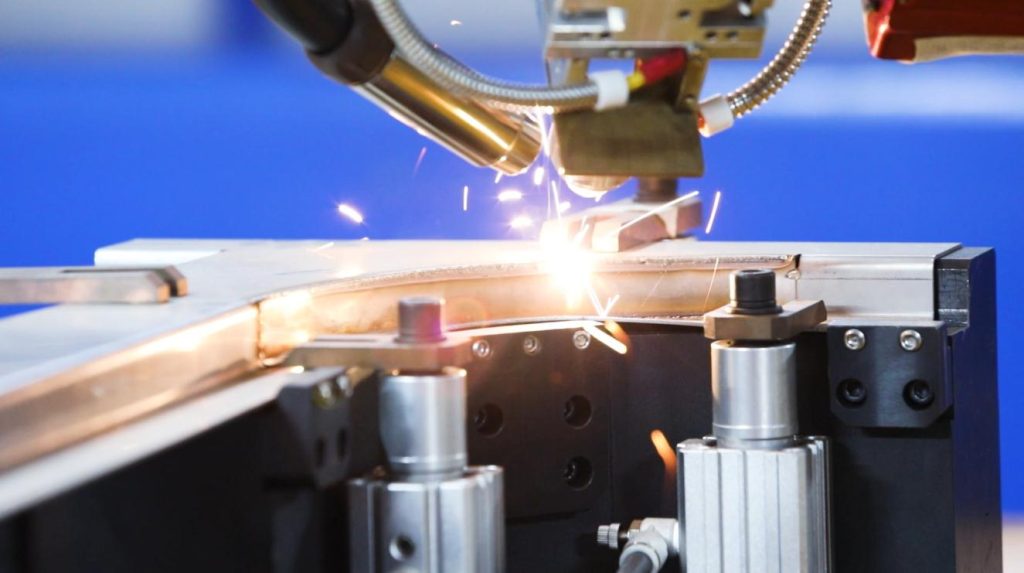

- Welding Station: The critical point where the seam is permanently fused using ERW, SAW, or another technology.

- Post-Weld Treatment: This includes weld bead trimming (scarfing), heat treatment to normalize the weld zone, and cooling.

- Sizing & Calibrating: A set of stands that fine-tune the pipe to its final, exact diameter and roundness.

- Cutting & Handling: Flying saws or torches cut the continuous pipe to length, followed by automated stacking, bundling, and testing equipment.

Technological Advancements and Quality Control

Modern machines are hubs of digital integration and precision:

- Automation & PLC Control: Entire processes are managed by Programmable Logic Controllers, ensuring consistent speed, alignment, and weld parameters.

- In-Line NDT (Non-Destructive Testing): Critical quality checks are embedded in the line. For ERW pipes, ultrasonic testing probes instantly inspect the entire weld length for flaws. For SAW pipes, X-ray inspection is commonly used.

- Hydraulic & Servo Systems: Provide the immense, yet precisely controlled, force required for forming and sizing thick-walled pipe.

- Laser Guidance & Vision Systems: Ensure perfect strip alignment into the mill, crucial for weld integrity.

The welded pipe making machine is a cornerstone of industrial manufacturing. Its evolution has enabled the production of stronger, more reliable, and more cost-effective pipes that meet the ever-growing demands of global infrastructure, energy transition, and construction. By continuously integrating advanced welding science, robotics, and real-time quality assurance, this machinery does more than bend metal—it forges the durable backbone of modern society, ensuring that the essential conduits for fluids, gases, and structural support are manufactured to the highest standards of safety and performance.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)